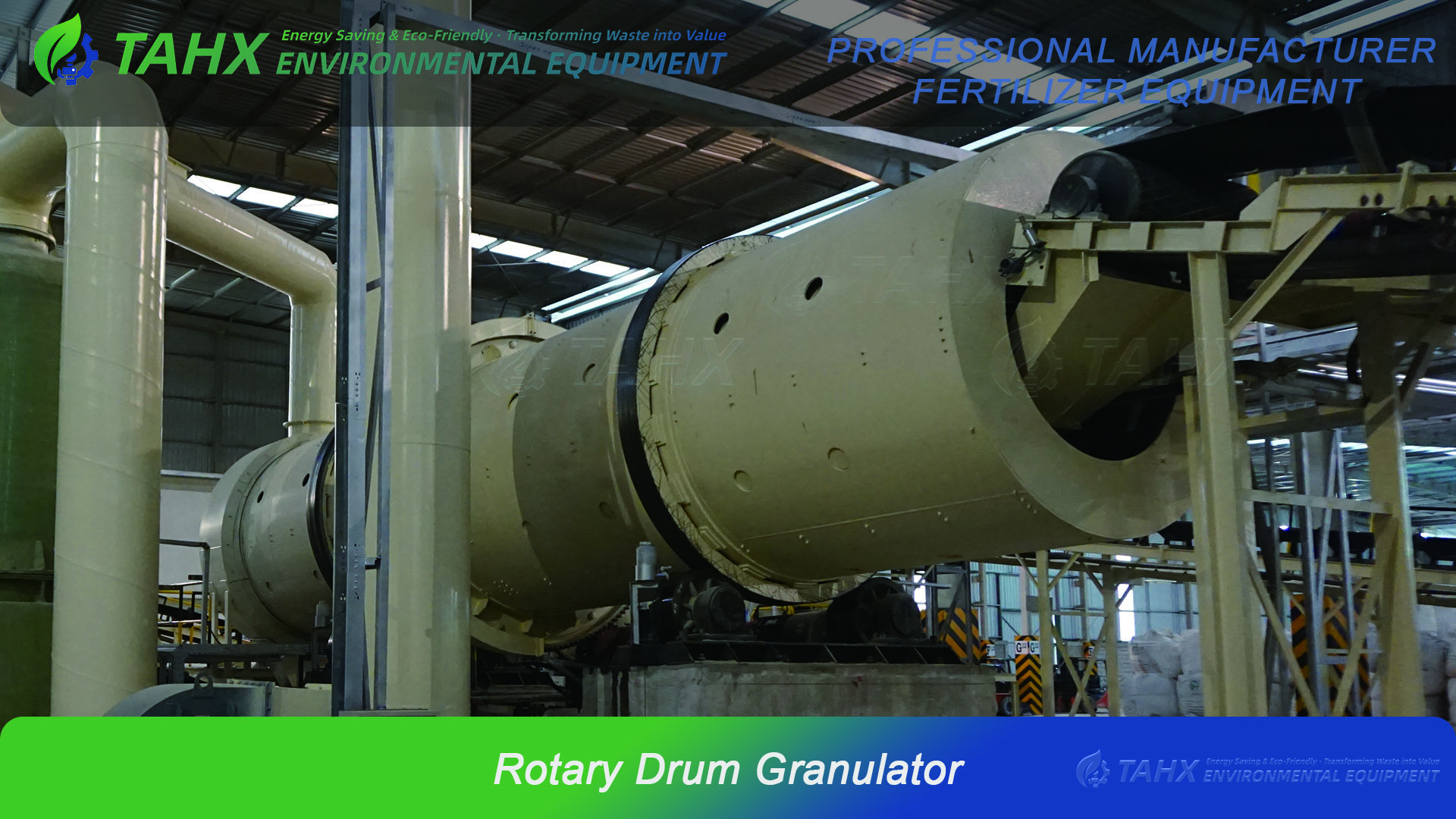

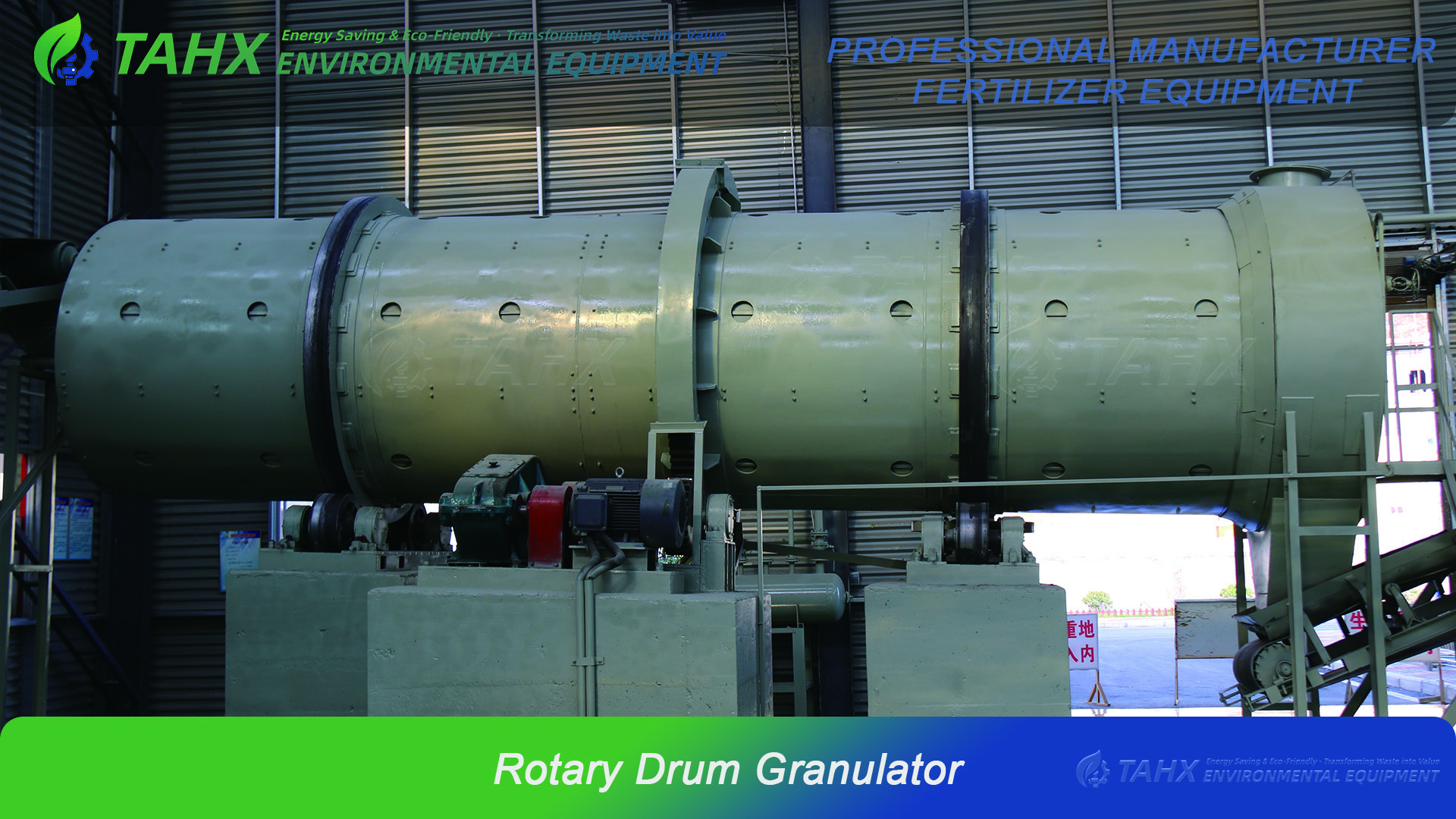

The Rotary Drum Granulator is a specialized machine that converts materials into spherical granules through a wet granulation process. It features a robust design consisting of a long horizontal cylinder mounted on heavy-duty support roller assemblies, driven by a high-torque motor and reducer via a large girth gear.

Description

1. Product Introduction

The Rotary Drum Granulator is a specialized machine that converts materials into spherical granules through a wet granulation process. It features a robust design consisting of a long horizontal cylinder mounted on heavy-duty support roller assemblies, driven by a high-torque motor and reducer via a large girth gear.

-

Applications: Primarily used for processing livestock manure, municipal sludge, household waste, fly ash, and various compound fertilizer formulations.

-

Structural Features: The interior is typically lined with specialized rubber sheets that are corrosion-resistant, acid-alkali resistant, and high-temperature tolerant. This prevents material from sticking to the walls (anti-caking) and significantly extends the equipment's lifespan.

-

Output: Produces dense, spherical granules with a typical diameter range of 2mm to 5mm.

2. Performance Characteristics

The Rotary Drum Granulator is a leading choice in the industry due to its high efficiency and stable operational profile:

-

High Granulation Rate: Under standard operation, the granulation rate exceeds 70%. It features a low return rate, and the return material has a small particle size, allowing for easy re-granulation.

-

Large-Scale Production: Compared to disc granulators, the rotary drum offers significantly higher single-machine capacity, making it ideal for continuous large-scale industrial production.

-

Superior Adaptability: Capable of handling various raw material formulas. It is particularly effective for materials involving steam or heat, utilizing the thermal energy to reduce the downstream drying load.

-

Exceptional Durability: The specialized lining system solves the common industry problem of material buildup while providing a powerful anti-corrosion barrier.

-

User-Friendly Operation: Features a high degree of automation, low maintenance costs, and low operational noise levels.

3. Working Principle

The operational logic of the Rotary Drum Granulator centers on the "Agglomeration" process, which can be broken down into four stages:

-

Feeding & Moistening: Base powdered materials enter the rotating drum via a belt conveyor. Simultaneously, water, steam, or chemical reactants (such as phosphoric acid or ammonia) are injected through spray pipes to achieve the optimal moisture and temperature for bonding.

-

Rolling Motion: As the drum rotates slowly, centrifugal force and friction carry the material upward. Upon reaching a certain height, the material rolls back down under the influence of gravity.

-

Nucleation & Growth: This continuous tumbling and squeezing creates shear and compressive forces. Fine powders begin to adhere to central nuclei, layer by layer, gradually forming spherical granules.

-

Polishing & Discharge: The drum is installed at a slight inclination (typically 2° to 5°). As the granules migrate toward the lower end, they are further polished and compacted by the rolling action. The finished granules are then discharged for the subsequent drying and cooling phases.

Tai'an Hongxin Environmental:

Supply of High-Quality and Efficient Fertilizer Production Equipment, Straw Processing Equipment, Waste Treatment Equipment and Mining Equipment. If you are looking for fertilizer production equipment and production lines, feel free to contact us at any time.- Whatsapp(Tel): + 86 139-0548-5429( Mr. Li)

- E-mail: tahongxin@gmail.com