Description

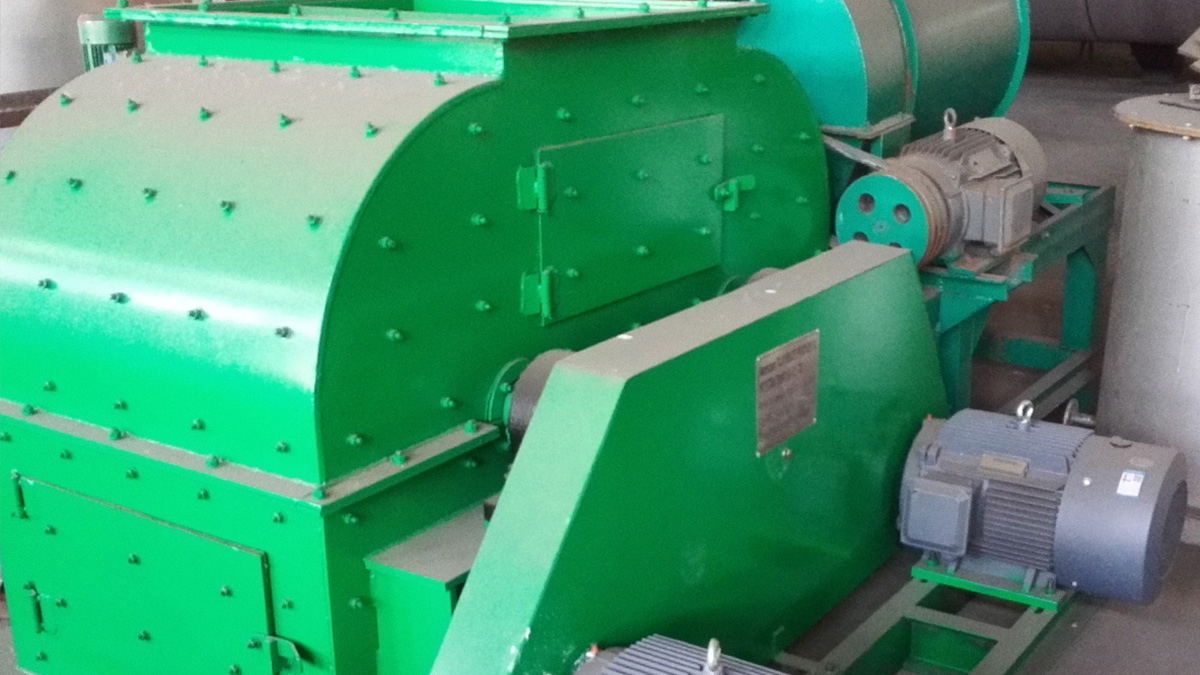

A dual-shaft horizontal shredder is a crushing machine characterized by its twin-shaft synchronous drive and horizontal structure. It is widely used in solid waste treatment, resource recovery, and other industries. Its core function is to shred large or tough materials into small particles by using the shearing, tearing, and squeezing action of two parallel rotating chain-equipped shafts.

1. Key Features

As an efficient shredding machine, the dual-shaft horizontal shredder is widely used across many fields due to its unique structure and performance. Here are its main features:

- Smart Structural Design: The shredder features a dual-shaft horizontal layout with two parallel main shafts equipped with staggered shredding chains. This design allows the material to be fully squeezed, sheared, and impacted between the two shafts, improving shredding efficiency. The compact overall structure also saves space, making it easy to install and arrange in a workshop.

- Excellent Shredding Performance: It can effectively shred a wide range of materials. It achieves an ideal shredding size for hard materials like ores and metal scrap, as well as tough materials like plastic and rubber. The shredding action is consistent, resulting in a uniform particle size that simplifies subsequent processing.

- High Production Efficiency: Since both shafts work simultaneously, the machine increases the contact opportunities between the material and the shredding chains, which speeds up the shredding process. Compared to a single-shaft shredder, it can handle a significantly higher volume of material in the same amount of time, making it ideal for large-scale industrial production.

- Simple and Safe Operation: The equipment has a complete control system, allowing operators to easily start, stop, and adjust the speed via a control panel. It also has multiple safety features, such as overload protection and feed port guards, to effectively prevent equipment damage and accidents caused by improper operation or material anomalies.

- Easy Maintenance: The shredding chamber is designed for easy access, which simplifies maintenance tasks like replacing and cleaning the shredding chains. The machine's critical components are made of high-strength, wear-resistant materials, which extends their service life and reduces maintenance frequency and cost. Additionally, a well-designed lubrication system makes it easy to add lubricant regularly to ensure normal operation.

- Wide Range of Applications: It can be used in mining, metallurgy, construction, chemical, and environmental industries. For example, it shreds ore in the mining industry and processes solid waste for resource recovery in the environmental sector. Different industries can choose the appropriate chain type and specifications based on their material properties and shredding requirements.

2. Application Scope

With its powerful shearing, tearing, and impacting capabilities, the dual-shaft horizontal shredder has wide and significant applications across several industries, including:

- Solid Waste Treatment: It's an indispensable tool for processing various types of solid waste. For municipal solid waste like kitchen scraps, waste paper, plastic bottles, and old clothes, the shredder can break it down into smaller particles, facilitating subsequent transportation, landfilling, incineration, or recycling. For industrial solid waste such as discarded rubber products, plastic offcuts, metal shavings, and wood chips, it effectively reduces their volume, creating favorable conditions for recycling. For example, shredded plastic can be re-pelletized, and metal shavings can be melted down and re-used.

- Medical Waste Disposal: Medical waste contains a large number of pathogens and harmful substances. Improper disposal can lead to severe contamination. This shredder can break down used syringes, IV tubes, and discarded medicine packaging into unrecognizable fragments, reducing their volume while also minimizing the risk of pathogen spread. This provides a crucial foundation for subsequent sterilization and harmless disposal.

- Agricultural Applications: It plays a vital role in agriculture by shredding crop stalks. The shredded stalks can be used as feed for livestock or returned to the fields as organic fertilizer to improve soil structure. Additionally, the shredder can effectively process agricultural waste like discarded plastic film and pesticide bottles, supporting green agricultural development.

- Resource Recovery: The dual-shaft horizontal shredder is an essential piece of equipment in the resource recovery industry. For example, in old tire recycling, it can shred tires into rubber granules of different sizes, which can then be used to make rubber tracks, recycled rubber products, and more. In waste paper recycling, it can shred waste paper into pulp, providing raw material for new paper production. For discarded appliances like refrigerators, washing machines, and TVs, the shredder can break down their casings and internal components, making it easier to separate recyclable materials like metal and plastic.

3. Components of a Dual-Shaft Horizontal Shredder

- Power System

- Motor: Provides the power source for the shredder, driving the reducer, which in turn drives the rotation of the shafts. Common motors include ordinary three-phase asynchronous motors. The type and power of the motor are selected based on the shredder's power requirements and the working environment.

- Shredding System

- Main Shafts: Two high-strength main shafts are the core power transmission components. They have welded chain seats connected to the chains with pins.

- Chains: The shredding chains are typically made of high-strength alloy steel, which offers high strength and wear resistance, allowing them to withstand the immense forces generated during shredding.

- Shredding Chamber: The space enclosed by the casing and other components. It's where the shredding chains shear, tear, and squeeze the material to complete the shredding process. The design of the chamber should consider material flow, shredding efficiency, and smooth discharge.

- Feeding and Discharge System

- Feed Port: Located at the top of the shredder, it's where the material to be shredded is fed into the chamber. The size and shape of the feed port are designed based on the shredder's processing capacity and material characteristics. Some shredders are also equipped with a feeding conveyor belt, hopper, and forced feeding mechanism to ensure uniform and consistent material entry.

- Discharge Port: Located at the bottom or side of the shredding chamber, it's used to discharge the shredded material. The size and shape of the port affect the discharge speed and particle size. Some shredders also have an adjustable plate at the discharge port to flexibly control the fineness of the discharged material.

- Support and Protection System

- Frame: Typically welded from high-quality carbon steel plates and channels, the frame is the supporting structure for the entire shredder. It is required to have sufficient strength and stability to ensure the shredder doesn't shake or deform during operation.

- Bearing Housing and Bearings: Used to support the shafts and bear the huge radial and axial loads generated during rotation. The bearing housings are typically made of high-strength cast iron. The bearings are selected based on the shaft speed and load requirements, with rolling bearings commonly used.

- Casing: A robust welded structure that supports all components and provides the shredding chamber. It also acts as a protective shield, preventing material from splashing out during shredding, which protects the safety of operators and the surrounding environment. To prevent some materials from sticking to and corroding the chamber, it is often lined with a PP or stainless steel plate.

- Protective Guards: These are used to cover moving parts of the transmission system and V-belt mechanism, preventing operators from coming into contact with them and ensuring safety. They also help prevent dust and debris from entering.

- Control System

- Electric Control Box: The core electrical components use products from brands like Schneider and Siemens. It controls the equipment's startup, operation, and shutdown. It includes safety features such as an emergency stop button, an overload protection relay, and a safety interlock device to ensure the shredder's safe operation and prevent equipment damage and accidents.

4. How to Choose a Dual-Shaft Horizontal Shredder

When choosing a dual-shaft horizontal shredder, you need to make a comprehensive decision based on your actual production needs, material characteristics, and the machine's core performance. An incorrect selection can lead to low production efficiency or wasted costs. Here is a specific analysis of key factors:

- Define Material Characteristics: A Fundamental Premise Different materials have vastly different requirements for the equipment. You must first clarify these core parameters:

- Material Hardness: The hardness of materials like construction waste (containing concrete and rebar), plastic scrap, and wood offcuts varies significantly. You need to match the appropriate chain strength. For high-hardness materials (e.g., ore, metal shavings), use high-alloy chain hammers. For low-to-medium hardness materials (e.g., straw, fabric), high-manganese steel chain hammers can be used to reduce costs.

- Material Moisture: If you're processing materials with a moisture content over 20% (e.g., kitchen waste, wet straw), you need to ensure the equipment has an anti-clogging design. The chains should be arranged in a staggered pattern to prevent material from sticking and accumulating.

- Material Viscosity: Highly viscous materials (e.g., rubber, resin) require a chamber with an anti-stick coating (like Teflon) and an increased chain speed (300-500 RPM is recommended) to use centrifugal force to reduce material adhesion.

- Match Equipment Specifications to Production Needs

- Throughput Requirements: Choose a model based on your required throughput per hour (e.g., 5 tons/hour, 20 tons/hour). Note that manufacturers' "theoretical throughput" is often based on ideal conditions (e.g., dry, loose material). For actual selection, it's recommended to build in a 20% buffer. For example, if you need 10 tons/hour, choose a machine with a capacity of 12-15 tons/hour to avoid accelerated wear from long-term full-load operation.

- Shredded Particle Size Requirements: Define the required size range for the finished product (e.g., 2-5mm, 10-20mm). The finer the required size, the higher the equipment's precision needs to be. If you need to flexibly adjust the size, choose a model with an adjustable screen. The screen mesh size can be changed within a range of 5-50mm.

- Focus on Core Equipment Performance: Durability and Stability

- Key Component Materials: The material of the core components in contact with the shredded material directly impacts their lifespan. The casing is recommended to be made of Q345 steel plate (at least 10mm thick) for better resistance to deformation than ordinary steel. The chains should be chosen based on the material: high-carbon steel (HRC55-60) for crushing ore, or Cr12MoV alloy for plastic (improves wear resistance by 30%). For bearings, choose imported brands (like SKF, NSK) to ensure stability at high speeds.

- Power System Configuration: The motor power must match the throughput and material hardness (e.g., 37-45kW motor for 10 tons/hour of construction waste). Prioritize a variable-frequency motor, which can automatically adjust speed based on material load to reduce energy consumption (saving 15%-20% compared to ordinary motors). It should also have an overload protection device (like an electromagnetic clutch) to prevent the motor from burning out during a jam.

- Sound Structural Design: The dual shafts' speed is critical—a high speed increases shredding force and efficiency. The feed port size must meet shredding needs, and the discharge port should have a slanted design to accommodate different conveying equipment (e.g., belt conveyors, screw conveyors).

- Consider Operating Costs and Safety: A Long-Term Guarantee

- Ease of Maintenance: Choose a design with quick-release chains (e.g., pinned instead of welded). The chamber should have a reserved inspection door for easy cleaning of residual material. A centralized lubrication system is recommended to reduce the frequency of manual maintenance.

- After-Sales Service and Value: Prioritize manufacturers with over 10 years of industry experience. Check their case studies (e.g., do they have successful applications in your industry?). After-sales service should include free installation and commissioning, and a list of spare parts (e.g., replacement cycle and cost of chains and bearings).

In short, when making your selection, follow this logical chain: "material characteristics → production needs → equipment performance → long-term cost." Combine this with a site visit (e.g., a test run at the manufacturer's facility using your actual material) to choose the best-suited dual-shaft horizontal shredder.

5. Rotary Drum Screen Pricing

The price is determined by factors such as product specifications, material of construction, and capacity, based on customer requirements. Please contact our sales team for a specific quote.

6. Company and Product Introduction

Founded in 1997, Tai'an Hongxin Environmental Protection Technology Co., Ltd. is located at the foot of Mount Tai, one of China's most famous mountains. Our facility spans 100,000 square meters, with 66,000 square meters of floor space. We hold an A2 pressure vessel manufacturing license and are ISO9001 certified. We are a high-tech enterprise in Shandong Province, a strategic partner of the Shandong Academy of Agricultural Sciences, and a member of the National Fertilizer Industry Technology Innovation Alliance.

Our team consists of 216 technical staff and over 100 sets of large, precision, and specialized processing equipment. Our professional technical and manufacturing teams provide comprehensive services, including technical consultation, process design, installation, commissioning, personnel training, and full turnkey project solutions. We also guarantee excellent after-sales service. Our products are sold both domestically and internationally, with exports to countries like Indonesia, the UAE, Malaysia, Vietnam, Bangladesh, and Myanmar.

Specification

| Specifications | Rotating Speed | Power | Capacity | External dimensions L*W*H |

| r/min | Kw | t/h | mm | |

| WSF600 | 1460 | 11*2 | 10-15 | 1680*1516*1100 |

| WSF800 | 1460 | 22*2 | 13*20 | 2000*1870*1700 |

Tai'an Hongxin Environmental:

Supply of High-Quality and Efficient Fertilizer Production Equipment, Straw Processing Equipment, Waste Treatment Equipment and Mining Equipment. If you are looking for fertilizer production equipment and production lines, feel free to contact us at any time.- Whatsapp(Tel): + 86 139-0548-5429( Mr. Li)

- E-mail: tahongxin@gmail.com