Description

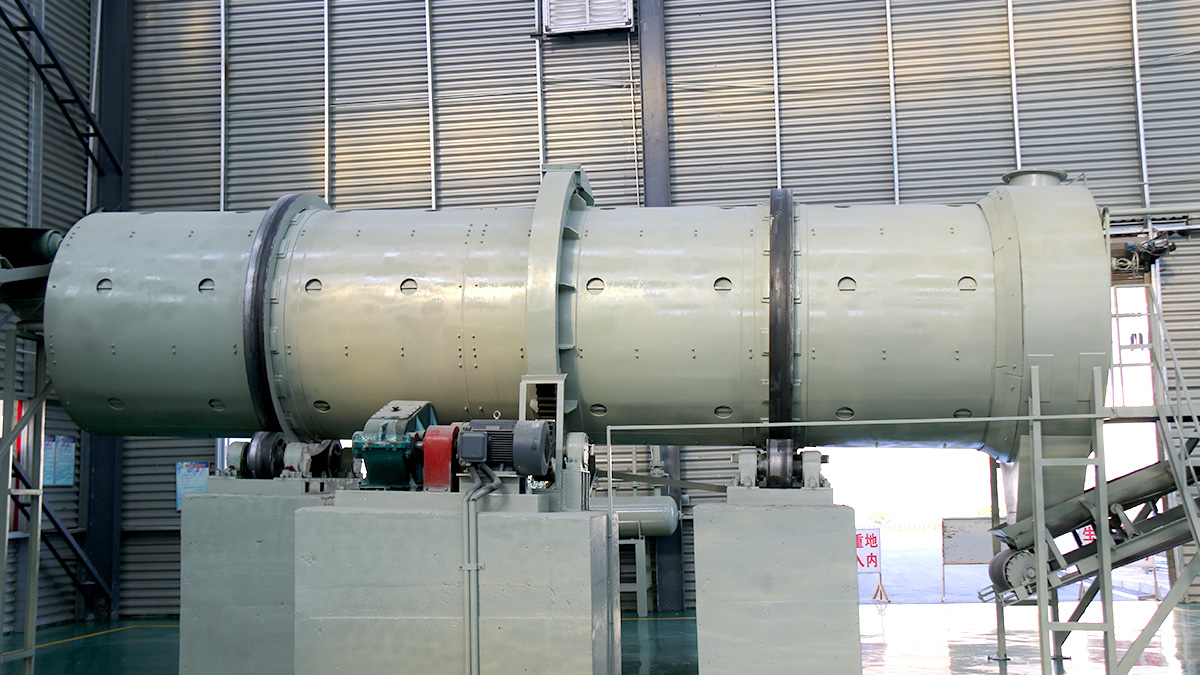

The drum granulator is a molding machine that processes powdered or slurry materials into spherical particles. It is widely used for large-scale production in industries like fertilizer and chemicals.

1. Key Features of the Drum Granulator

1.1 Structural Design

- Special Liner: The cylinder features a special rubber or acid-resistant stainless steel liner. This design automatically removes buildup and prevents lumping, eliminating the need for traditional scrapers. This not only reduces equipment failures and maintenance but also improves the equipment's corrosion and wear resistance, extending its service life.

- Robust and Durable Construction: The support frame is welded from medium carbon steel plates and channel steel, allowing it to withstand the significant forces from the rotating parts. The main body is also welded from high-quality medium carbon steel, ensuring a sturdy structure and high stability.

1.2 Operation and Maintenance

- Simple Operation: The equipment is user-friendly and doesn't require advanced technical skills to operate. Its high level of automation saves labor costs and reduces manual labor intensity.

- Low Maintenance Cost: With a relatively simple structure, stable operation, minimal wear, and few wearing parts, the drum granulator has low costs for repairs and part replacement. This reduces production downtime and ensures continuous operation for your business.

1.3 Production Capacity

- High Output: The drum granulator is designed for continuous production. As the material tumbles inside the cylinder, it forms granules that gradually grow and flow out of the discharge port. This enables large-scale, high-volume production to meet a variety of needs.

- Flexible Production: Its production capacity is highly flexible. You can easily adjust the output by changing parameters like feeding speed, cylinder rotation speed, and inclination angle, making it adaptable to different production scales and output requirements.

1.4 Product Quality

- High Granulation Rate: The granulation rate can reach approximately 70%. The small amount of return material can be re-granulated, effectively increasing raw material utilization and reducing waste.

- Superior Strength and Appearance: The resulting granules have high compressive strength and stability, making them resistant to breakage during storage and transportation. They also have excellent appearance, with high sphericity and uniform particle size, meeting market demands for quality products.

- High Drying Efficiency: By introducing steam for heating, the material temperature increases, resulting in lower moisture content after granulation. This improves efficiency in the subsequent drying process and reduces drying costs.

1.5 Material Adaptability

- Wide Application Range: The drum granulator is highly adaptable and can process various types of materials. These include organic materials like livestock manure, straw, and sludge, as well as basic fertilizers like nitrogen, phosphorus, and potassium, and other additives. It is suitable for producing various fertilizers, including compound, organic, bio-organic, and controlled-release fertilizers, and can be used for granulation in other industries as well.

- Flexible Formulation: The equipment places minimal restrictions on raw material formulation. You can easily adjust the ratio and types of materials to produce different granulated products with varying nutrient contents and properties, based on specific product requirements.

2. Applications in Fertilizer Production

The drum granulator has a wide range of applications, especially in fertilizer production:

- Compound Fertilizer Production: It is suitable for large-scale production of high, medium, and low concentration compound fertilizers. It can uniformly mix and granulate various basic fertilizer raw materials like urea, monoammonium phosphate, and potassium chloride, forming composite fertilizer granules with specific strength and size.

- Organic Fertilizer Production: It can process organic waste from livestock manure, crop straw, municipal solid waste, and the food and beverage industry. After fermentation, these organic materials can be directly granulated into organic fertilizer, which helps improve soil fertility and structure.

- Bio-Organic-Inorganic Fertilizer Production: The granulator can mix various organic waste materials with inorganic fertilizers. It is an ideal piece of equipment for producing bio-organic-inorganic fertilizers, which combine the benefits of both organic and inorganic fertilizers.

3. Equipment Components

The drum granulator is composed of several basic and auxiliary components:

3.1 Basic Components

- Support Roller Section: This part supports the entire rotating body. The roller base is typically welded from medium carbon steel plates and meets strict quality standards. The rollers are made of high-quality anti-corrosion and wear-resistant materials (usually cast steel) to extend their service life. Each roller bearing seat has a tensioning device for position adjustment, and lifting hooks are provided on the four corners of the roller frame for easy loading and unloading.

- Transmission Section: This includes the main motor, belt pulleys, V-belts, a reducer, a main shaft, and a nylon pin coupling. The main motor, mounted on the transmission frame, drives the pulleys and V-belts. The reducer then transmits power to the main shaft to operate the machine. The reducer and main shaft are coupled using a nylon pin coupling to transmit the drive.

- Large Gear: Fixed to the main body, it meshes with the transmission pinion to drive the machine. It is typically made from a cast steel blank, machined on a vertical lathe, and then hobbed on a gear hobbing machine.

- Roller Ring: Fixed at both ends of the cylinder, it supports the entire body.

- Cylinder Body: This is the core component of the drum granulator. It is welded from high-quality medium carbon steel plates and features a special rubber or acid-resistant stainless steel liner that automatically removes buildup, eliminating the need for traditional scrapers.

3.2 Auxiliary Components

- Feeding Device: This usually includes a feeding box, which allows materials to enter the front end of the rotating cylinder. The inclination of the feeding box must be greater than the material's natural angle of repose to ensure a smooth flow.

- Spraying Device: Installed inside or above the cylinder, it uniformly sprays liquid binders or water to achieve the optimal moisture content for granulation and promote material agglomeration.

- Hot Air System: Some drum granulators are equipped with a hot air system to evaporate moisture during granulation, enhance particle strength, and improve drying efficiency. This system typically includes a hot air furnace, ducts, and a hot air distributor.

- Material Retainer Ring: Fixed to the front and rear walls of the drum, it prevents internal materials from being discharged too early.

4. How to Choose a Drum Granulator

Choosing a drum granulator requires a comprehensive evaluation of your production needs, material properties, equipment performance, and long-term operating costs. This approach helps avoid issues like low production efficiency and rapid equipment wear due to improper selection. Here are the key factors to consider:

4.1 Define Core Production Needs: Capacity and Application

- Capacity: This is the primary indicator. Determine your required daily or hourly output (e.g., 5, 20, or 50 tons per hour) to select the right equipment size. Small models (under Φ1.2×4m) are suitable for small workshops with an annual output of thousands of tons. Medium models (around Φ1.8×6m) are a good fit for medium-sized factories with an annual output of 100,000 to 300,000 tons, while large models (over Φ2.2×8m) are for large-scale production exceeding 500,000 tons annually.

- Application: Consider the specifics of your production scenario. For batch production, a single machine with a simple production line may suffice. For continuous production, pay attention to how the equipment integrates with upstream and downstream processes (e.g., crushing, drying, screening), and if it has interfaces for automation.

4.2 Match Material Characteristics: Avoiding Incompatibility Different material properties directly impact the granulation outcome. You need to choose a model that's a good match:

- Moisture Content: For high-moisture materials (e.g., over 30% for fermented organic fertilizer), select a model with a hot air jacket to control moisture. For low-moisture materials (e.g., dry powder feed), you'll need a wetting device to prevent the granules from being too loose.

- Stickiness and Hardness: For sticky materials (e.g., molasses feed), choose a drum with a non-stick coating (like Teflon) or scrapers to prevent material from sticking to the cylinder wall. For materials with coarse fibers or hard particles (e.g., straw-mixed fertilizer), ensure the internal mixing blades are strong enough to prevent blockages or wear.

4.3 Focus on Core Configuration: Materials, Energy, and Stability

- Material Contact Parts: The material of these parts is crucial for equipment lifespan. For standard materials (like inorganic fertilizer), Q235 carbon steel is a good choice. For corrosive materials (like fertilizers containing NPK), opt for 304 or 316 stainless steel. For high-hardness materials (like mineral powder), the cylinder liner should be high-manganese steel or wear-resistant cast iron to reduce wear.

- Transmission and Drive System: A quality drum granulator should use a gear reducer instead of a belt drive for stable speed (typically 5-15 RPM). The motor should be a high-quality copper-wire motor with power that matches the capacity (e.g., a 10-ton/hour capacity usually requires a 15-22kW motor) to prevent overloading or energy waste.

- Wearing Parts: Check the materials and ease of replacement for wearing parts like mixing blades, support rollers, and seals. For example, detachable mixing blades are easier to replace, which reduces downtime.

4.4 Balance Cost and Long-Term Return: Beyond the Purchase Price

- Initial Investment vs. Operating Cost: A low-priced machine may use inferior motors or thin steel plates, saving money initially but leading to costly repairs later (e.g., motor burnout, cylinder deformation). A higher-quality machine may cost more upfront but has lower energy consumption (e.g., 10-20% less power for the same output) and a longer service life for wearing parts (e.g., stainless steel blades can last 2-3 years vs. 6-12 months for carbon steel).

- Automation vs. Labor Costs: Highly automated equipment (with PLC control, automatic temperature control, and fault alarms) can save on labor costs by reducing the need for 2-3 operators, though the initial investment may be 10-30% higher. For small-scale production with low labor costs, a basic model with manual adjustments may be more cost-effective.

4.5 Research the Manufacturer and After-Sales Service

- Choose Reputable Manufacturers: Prioritize manufacturers with over 10 years of experience and a track record of granulating materials similar to yours. Avoid small factories that simply assemble parts from other suppliers. Check if their workshop has large-scale processing equipment (like CNC lathes) to ensure key components are made in-house.

- After-Sales Support: Clarify the scope of after-sales service. Does it include free installation, a warranty of at least one year, and lifetime technical support? Also, confirm the lead time for wearing parts (e.g., a 72-hour delivery guarantee). For remote locations, check if the manufacturer can coordinate with local service partners to avoid production delays.

In short, the core logic for choosing a drum granulator is "needs matching + solid configuration + controllable costs." First, define your capacity, material properties, and budget. Then, compare materials, energy consumption, and manufacturer reputation. Finally, make your decision based on after-sales service and long-term benefits.

5. Drum Granulator Pricing

Pricing is determined by customer requirements, including product specifications, material of construction, and capacity. Please contact our sales team for a specific quote.

6. About Our Company and Products

Founded in 1997, Tai'an Hongxin Environmental Protection Technology Co., Ltd. is located at the foot of Mount Tai, one of China's most famous mountains. Our facility spans 100,000 square meters, with 66,000 square meters of floor space. We hold an A2 pressure vessel manufacturing license and are ISO9001 certified. We are a high-tech enterprise in Shandong Province, a strategic partner of the Shandong Academy of Agricultural Sciences, and a member of the National Fertilizer Industry Technology Innovation Alliance.

Our team consists of 216 technical staff and over 100 sets of large, precision, and specialized processing equipment. Our professional technical and manufacturing teams provide comprehensive services, including technical consultation, process design, installation, commissioning, personnel training, and full turnkey project solutions. We also guarantee excellent after-sales service. Our products are sold both domestically and internationally, with exports to countries like Indonesia, the UAE, Malaysia, Vietnam, Bangladesh, and Myanmar.

Specification

| Specifications | Cylinder | Capacity |

External dimensions L*W*H |

||||

| Inclination | Inner diameter | Length | Rotating Speed | Power | |||

| ° | mm | mm | r/min | Kw | t/h | mm | |

| ZG1405 | 2-2.5 | 1400 | 5000 | 14 | 7.5 | 3-8 | 5000*1950*2100 |

| ZG1606 | 2-2.5 | 1600 | 6000 | 11.5 | 11 | 5-8 | 6000*2100*2400 |

| ZG1807 | 2-2.5 | 1800 | 7000 | 11.5 | 18.5 | 8-10 | 7000*2200*2800 |

| ZG2008 | 2-2.5 | 2000 | 8000 | 11 | 22 | 10-15 | 8000*2600*3200 |

| ZG2210 | 2-2.5 | 2200 | 10000 | 10.5 | 37 | 15-20 | 10000*2800*3400 |

| ZG2410 | 2-2.5 | 2400 | 10000 | 9 | 45 | 20-25 | 10000*3220*3900 |

| ZG2610 | 2-2.5 | 2600 | 10000 | 8.3 | 55 | 25-30 | 10000*3500*4200 |

| ZG3010 | 2-2.5 | 3000 | 10000 | 8.3 | 75 | 30-35 | 10000*3900*4600 |

| ZG3210 | 2-2.5 | 3200 | 10000 | 8.3 | 90 | 35-40 | 10000*4100*4800 |

For customization, please contact us by phone or email.

Tai'an Hongxin Environmental:

Supply of High-Quality and Efficient Fertilizer Production Equipment, Straw Processing Equipment, Waste Treatment Equipment and Mining Equipment. If you are looking for fertilizer production equipment and production lines, feel free to contact us at any time.- Whatsapp(Tel): + 86 139-0548-5429( Mr. Li)

- E-mail: tahongxin@gmail.com