Description

A belt scale is a dynamic and continuous weighing device primarily used for the real-time and cumulative measurement of bulk materials (such as coal, ore, grain, and sand) transported on a belt conveyor. By integrating weighing sensors with the conveyor system, it performs non-contact or contact-based weight detection as materials move continuously on the belt, enabling precise monitoring of material flow, cumulative weight, and other data.

1. Key Features of Belt Scales

1. High Measurement Accuracy

- Accurate Dynamic Weighing: Utilizing advanced sensor technology and digital filtering, a belt scale can effectively suppress interfering factors like mechanical vibration and belt tension fluctuations during material transportation, achieving high-precision weighing. For example, the ICS-14 electronic belt scale has a dynamic cumulative error of less than ±0.125%.

- Multi-Point Measurement: By installing multiple weighing sensors and idlers on the weighing frame, multi-point load distribution is measured to ensure accurate material weight and minimize the impact of off-center loading on precision, as seen in the ICS-17A/B electronic belt scale.

2. Stable and Reliable Operation

- Modular Design: Components are designed with a modular structure, which facilitates easy installation, disassembly, and maintenance. If a component fails, it can be quickly replaced, reducing equipment downtime.

- Excellent Sealing and Protection: Key electrical components are sealed, and the scale frame has good sealing properties to effectively prevent dust, moisture, or corrosive substances from entering the equipment. This extends its service life and ensures long-term stable operation in harsh environments.

- High Belt Stability: Optimized belt tensioning mechanisms and anti-deviation devices ensure the stability of the belt during operation, reducing belt run-off and slippage to guarantee smooth material transport and weighing.

3. Intelligent Control Capabilities

- Adaptive Adjustment: Equipped with an adaptive PID control system, it can automatically adjust the feeding rate based on instantaneous flow deviations, keeping the feed rate within the set range for precise batching control.

- Self-Diagnosis: Some high-end models feature self-diagnosis functions that monitor operational parameters like belt deviation, sensor status, and feeding conditions in real time. If an anomaly is detected, it triggers an alarm and identifies the cause of the fault, allowing maintenance personnel to quickly troubleshoot the issue.

- Data Transmission and Integration: It can be seamlessly connected with control systems like DCS and PLC to transmit real-time weighing data and equipment status to the central control room, enabling remote monitoring and automated management. Integration with IoT modules also allows for remote monitoring and big data analysis.

4. Wide Range of Applications

- Broad Industry Coverage: Widely used in heavy industries such as metal mining, cement plants, and thermal power plants to precisely control the ratio and transport volume of bulk materials like ore, clinker, and pulverized coal. In chemical production, it's used for the batching and continuous feeding of granular and powdered raw materials. It also plays a crucial role in agricultural processing, such as grain drying and feed mixing. In environmental industries, like wastewater and sludge treatment, and waste-to-energy plants, it enables quantitative addition of treatment agents and precise mixing for high-calorific-value waste incineration.

- Diverse Material Types: Capable of weighing various bulk materials, including coal, ore, grain, fertilizer, cement, and pulverized coal, accurately measuring lump, granular, or powdered materials.

5. Optimized Structural Design

- Full Suspension Structure: The ICS-14 electronic belt scale, for instance, uses a full suspension weighing frame with no pivot points or moving parts. This reduces friction and errors in the force transmission process while also minimizing maintenance.

- Rectangular Steel Tube Main Beam: The main beam of the weighing frame typically uses a rectangular steel tube design, providing high rigidity and low self-weight. This design also minimizes the surface area for dust accumulation, helping to maintain weighing accuracy.

2. Application Scenarios of Belt Scales

As a dynamic and continuous weighing device, the belt scale is widely used across various industries and scenarios due to its ability to measure weight in real time during material transport. It plays a critical role in production monitoring, trade settlement, and cost control.

1. Industrial Production

Belt scales are very common in industrial production.

- Coal Industry: Used at mine shafts, coal preparation plants, and power plant coal transport systems to monitor coal flow in real time, helping companies track production progress, control energy consumption, and provide accurate data for internal accounting and sales.

- Metallurgy: In steel plants, belt scales ensure the precise proportioning of raw materials like iron ore and coke during transport, which guarantees the stability of the smelting process and improves product quality.

- Chemical Industry: Belt scales can meet the continuous and accurate weighing needs for various granular and powdered chemical raw materials, assisting in the automated control of chemical production processes.

- Fertilizer Manufacturing: Crucial for the accurate proportioning and transport of various fertilizer raw materials, which affects key factors like composition and efficacy.

2. Transportation

The transportation industry also relies on belt scales.

- Ports and Terminals: Large quantities of bulk goods (e.g., grain, ore, sand) are loaded and unloaded via belt conveyors. Belt scales can provide real-time data on the weight of goods, offering a reliable basis for cargo handling, delivery, and transportation cost settlement, improving logistics efficiency and reducing weighing disputes.

- Railway Freight Stations: For bulk goods transferred via belt conveyors, a belt scale can quickly complete the weighing process, facilitating freight volume statistics and scheduling.

3. Construction and Building Materials

This is another key application area for belt scales.

- Cement Plants: The production process requires precise weighing and proportioning of raw materials like limestone, clay, and iron powder. A belt scale can reliably perform this task, ensuring the quality of cement raw meal and clinker.

- Concrete Batching Plants: The weighing of aggregates like sand, stone, and cement directly affects the strength and performance of concrete. The real-time weighing function of a belt scale ensures accurate proportioning of each component, improving the stability of the final product.

- Stone Quarries and Gravel Yards: Belt scales are used to weigh mined and processed aggregates, which is convenient for sales and inventory management.

4. Grain Processing and Storage

Belt scales are highly useful in this sector.

- Grain Acquisition: When acquiring grain like wheat, corn, or rice, a belt scale can quickly weigh it as it's transported on a conveyor, improving efficiency and avoiding the tediousness and errors of manual weighing.

- Grain Processing Plants: Belt scales provide precise data for material transport and flow during processing, helping companies with production control and cost accounting.

- Warehouse In/Outbound: Belt scales accurately record the amount of grain entering and leaving the warehouse, ensuring the accuracy of inventory data.

Besides these major industries, belt scales are also used in environmental protection and mining. For example, they enable efficient and precise weight monitoring of waste transport in waste treatment plants and ore transport in mines, providing strong support for production management and decision-making.

3. Components of a Belt Scale

A belt scale is mainly composed of a weighing frame, a weighing sensor, a speed sensor, and a control instrument. Here is a detailed breakdown:

1. Load-Bearing and Transport Unit

- Weighing Frame: A vital component of the belt scale. It supports the belt and the material, and transmits the material's weight to the weighing sensors. Common structures include single-lever, dual-lever, cantilever, and full suspension types.

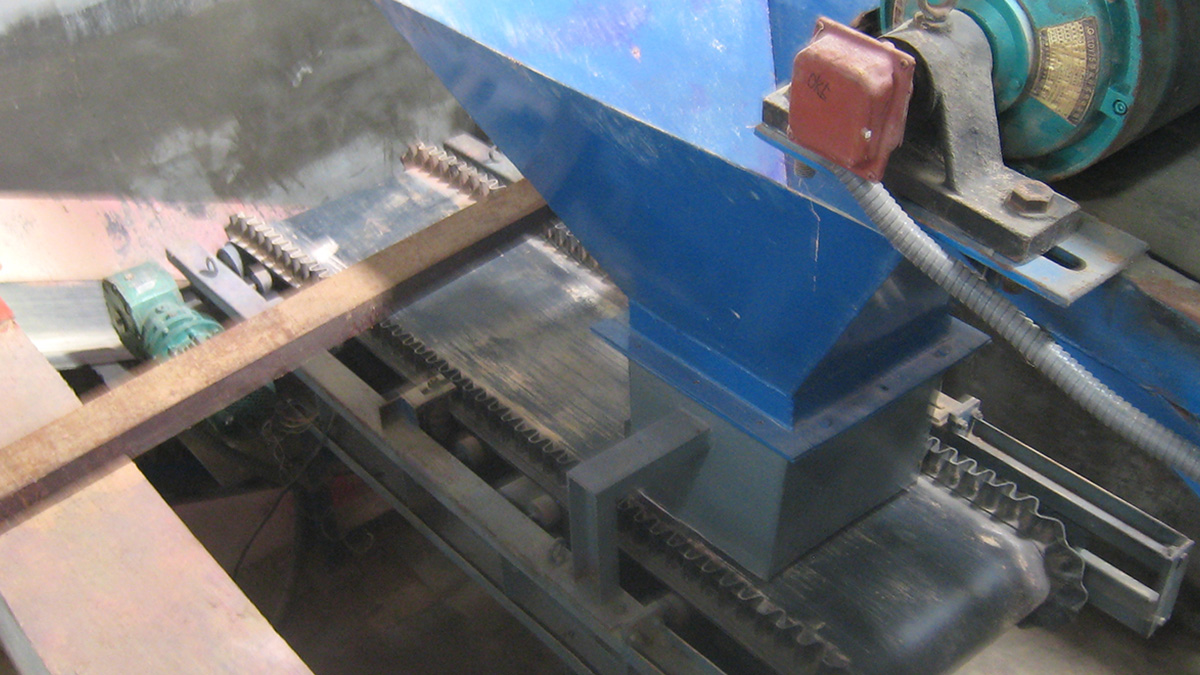

- Belt Conveyor: Used for transporting materials. The stability of its performance significantly impacts the accuracy of the belt scale. It includes components like the belt, idlers, rollers, and drive unit. When materials on the belt pass over the weighing frame, their weight is detected.

2. Detection Unit

- Weighing Sensor: One of the core components. Its primary function is to convert the weight signal from the weighing frame into an electrical signal. It typically uses a resistance strain gauge or a high-precision metal sealed sensor, characterized by high accuracy, stability, and reliability.

- Speed Sensor: Used to measure the running speed of the belt. Common types include DC pulse speedometers and digital brushless pulse generators. The speed sensor is installed on the tail pulley, speed-measuring pulley, or speed-measuring wheel. It emits a series of pulse signals to indicate the belt's speed, with the pulse frequency being proportional to the belt speed.

3. Signal Processing and Control Unit

- Control Instrument: Also known as the integrator, it is the "brain" of the belt scale. It receives signals from the weighing and speed sensors, processes them, and displays parameters like instantaneous flow and cumulative weight. It can also perform control and adjustments based on preset parameters, such as controlling the feeding speed of the feeding equipment for accurate batching.

- Data Collector: Collects signals from the weighing and speed sensors and converts them into digital signals for processing and analysis by the control instrument. Common data acquisition devices include centralized multi-channel AD acquisition boards or distributed digital signal collectors.

4. Auxiliary Units

- Tensioning Device: Adjusts the belt tension to ensure it maintains proper tightness during operation, reducing slippage and deviation, and improving weighing accuracy. Common tensioning methods include screw, gravity weight, and hydraulic tensioning.

- Anti-Deviation Device: Prevents the belt from running off-center, ensuring even material distribution on the belt, and thereby improving weighing accuracy. This is typically achieved by installing deviation switches and self-aligning idlers.

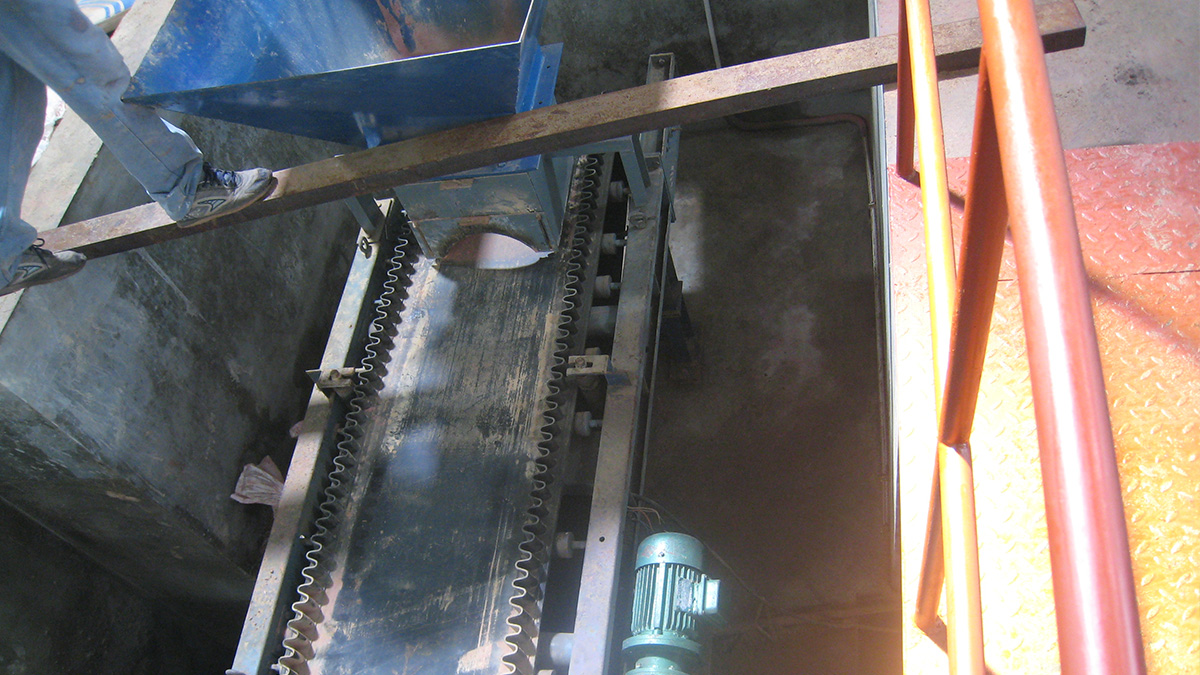

- Cleaning Device: Removes residual material from the belt, preventing it from affecting the scale's accuracy and also protecting the belt to extend its service life. Common cleaning devices include scraper cleaners and brush cleaners.

- Calibration Device: Used for regular calibration and verification of the belt scale to ensure its accuracy meets requirements. Common calibration methods include static weight calibration, chain weight calibration, and material calibration.

4. How to Choose a Belt Scale

When selecting a belt scale, you need to consider the specific operating conditions, measurement requirements, and environmental factors. Improper selection can lead to measurement errors, equipment damage, or production downtime. Here is a detailed guide on how to choose the right one:

1. Define the Application and Core Requirements

- Process Control / Material Monitoring: Focus on stability and real-time performance. Accuracy requirements can be relaxed to ±1% to ±2%. For example, for material proportioning on a production line, a simple and easy-to-maintain weighbridge belt scale is a good choice.

- High-Flow / Heavy-Duty Applications: For scenarios like mine conveyors (with flow rates of hundreds of tons per hour), focus on the equipment's load-bearing capacity. Choose a heavy-duty scale body that is impact-resistant and durable to prevent sensor damage from material impact.

2. Match Belt and Material Characteristics

The accuracy of a belt scale is directly affected by the belt and material properties. Pay close attention to these parameters:

- Belt Parameters:

- Belt Width (common range 500mm-2000mm) determines the scale length. It must match the conveyor belt width exactly (with an error no greater than ±50mm), otherwise, material spillage or measurement blind spots can occur.

- Belt Speed (typically 0.5-3m/s) must be compatible with the scale's speed sensor. High-speed belts require sensors with high-frequency sampling to prevent data lag.

- Material Characteristics:

- For granular materials (e.g., sand), focus on the scale's impact resistance to prevent measurement fluctuations from falling material.

- For powdered materials (e.g., cement), choose a sealed structure to prevent dust from entering the sensor and affecting accuracy.

- For corrosive materials (e.g., chemical raw materials), select a scale body made of 304 stainless steel to prevent corrosion.

3. Evaluate Installation and Environmental Conditions

Environmental and installation conditions are key to long-term stable operation. Check these factors in advance:

- Installation Space: The belt scale must be installed on a straight section of the conveyor belt. There should be a sufficient "empty section" (usually 5 times the belt width before and 3 times after) to prevent belt run-off or tension changes from affecting measurement. If space is limited, a compact cantilever belt scale can be used, but note that its accuracy may be slightly reduced by belt tension.

- Environmental Factors:

- For high-temperature environments (e.g., steel mills), choose a high-temperature resistant sensor (operating temperature -40°C to 120°C).

- For humid/dusty environments (e.g., cement plants), the equipment's protection rating should be IP65 or higher, and it should have an automatic cleaning function (e.g., with a scraper to remove sticky material).

- For explosion-proof areas (e.g., coal mines), select an explosion-proof certified model (Ex dⅡCT4) to prevent sparks from igniting hazards.

4. Consider Functions and Maintenance Costs

Choose additional features based on your needs to avoid over-investment.

- Calibration Functions: Automatic calibration (e.g., with a chain weight or cyclic chain weight) can reduce manual maintenance costs and is suitable for continuous production lines. Manual calibration is suitable for smaller production lines with frequent shutdowns.

- Data Integration: For applications that need to interface with ERP or MES systems, choose a smart model with 4G/Ethernet ports and support for the Modbus protocol for real-time data uploading.

- Maintenance Costs: The ease of replacing wear parts (e.g., idlers, sensors) is very important. Well-known brands (like Cimo Electric, Siemens) have strong parts compatibility, leading to lower long-term maintenance costs.

5. Verify Certifications and After-Sales Service

- Certifications: Prioritize products certified by OIML (International Organization of Legal Metrology), NTEP (National Type Evaluation Program), or China's CMC (Manufacturing Measuring Instruments License) to ensure legal metrology compliance.

- After-Sales Service: Belt scales require regular calibration (usually every 3-6 months). Confirm whether the manufacturer provides on-site calibration services. For remote areas, check the response time (a 24-hour on-site arrival is recommended) to prevent production stoppages due to equipment failure.

Summary: The Four-Step Selection Method

- Determine the application (settlement / control / heavy-duty) → 2. Match belt and material parameters (belt width / speed / material characteristics) → 3. Assess installation and environmental constraints (space / temperature and humidity / explosion-proof needs) → 4. Select functions and services (calibration / data integration / after-sales support). By following these four steps, you can significantly reduce the risk of selection errors and ensure the belt scale provides accurate weighing value to your production process.

5. Belt Scale Pricing

Pricing depends on the customer's required product specifications, material, and capacity. For a specific quote, please contact customer service.

6. Company and Product Profile

Tai'an Hongxin Environmental Protection Technology Co., Ltd. was established in 1997. Located at the foot of Mount Tai, one of China's Five Great Mountains, the company covers an area of 100,000 square meters with a building area of 66,000 square meters. It holds an A2-level pressure vessel manufacturing license and is certified under the ISO 9001 quality management system. The company is a Shandong Province High-Tech Enterprise, a strategic partner of the Shandong Academy of Agricultural Sciences, and a member of the National Fertilizer Industry Technology Innovation Alliance.

The company has a technical staff of 216 and over 100 large, precision, and rare product processing equipment sets. Our professional technical team and highly skilled manufacturing and installation crew provide customers with technical consulting, process design, installation, commissioning, personnel training, and turnkey project services. We also guarantee comprehensive after-sales support. Our products are sold both domestically and internationally, with exports to Indonesia, the UAE, Malaysia, Vietnam, Bangladesh, Myanmar, and other countries.

Tai'an Hongxin Environmental:

Supply of High-Quality and Efficient Fertilizer Production Equipment, Straw Processing Equipment, Waste Treatment Equipment and Mining Equipment. If you are looking for fertilizer production equipment and production lines, feel free to contact us at any time.- Whatsapp(Tel): + 86 139-0548-5429( Mr. Li)

- E-mail: tahongxin@gmail.com