Description

A urea melt granulation production line is a piece of equipment used for producing granular urea fertilizer. Here is an overview of its process principles, main equipment, production flow, and process features.

I. Process Principles

- Urea Melt Creation and Function: Granular urea is heated in a melter, quickly transforming it into a molten urea liquid. This process fundamentally reduces the formation of biuret since no water is added and no stirring is needed. The molten urea acts not only as a raw material but also as a liquid phase and binder, helping to form granules and providing heat to accelerate drying.

- Granulation Mechanism: The molten urea is fed in precise amounts into the granulation system, where it's mixed with fresh materials and recycled fines. Inside the granulator, the materials are bound by the molten urea, gradually forming granules through rolling and agglomeration. The heat provided by the urea also raises the material's temperature, reducing its moisture content and promoting the spheroidization and drying process.

II. Main Equipment

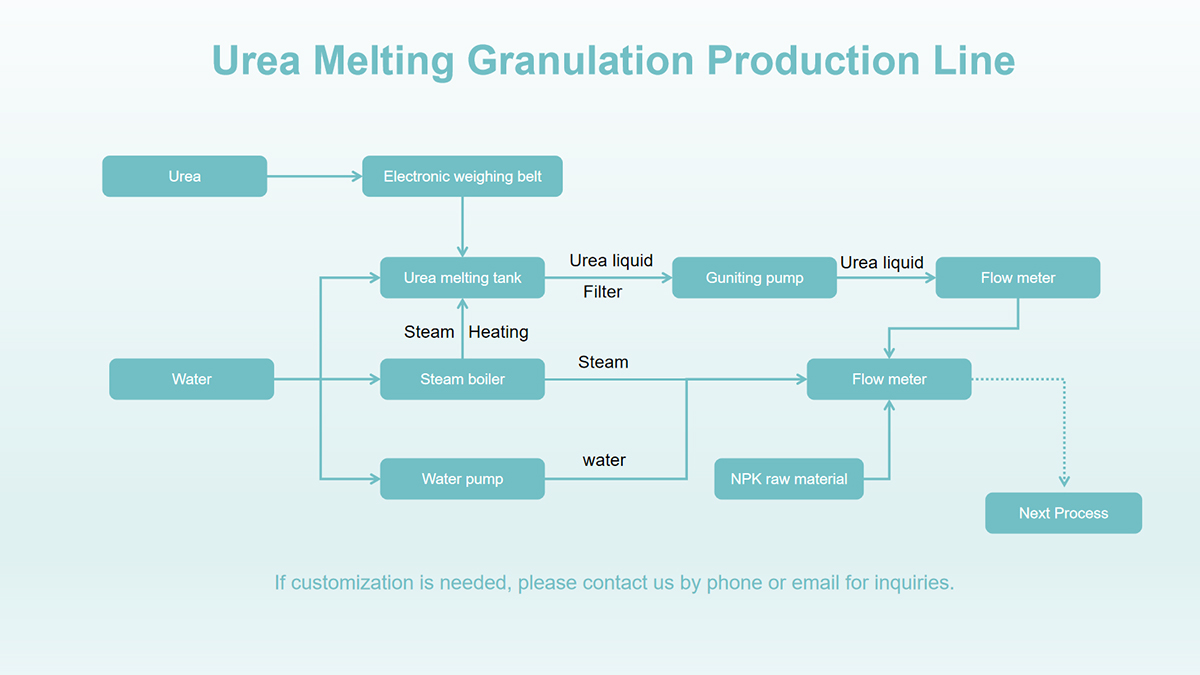

- Melting System: This includes a melting tank and heating device used to heat and melt urea into a liquid. The melting tank is typically made of stainless steel to prevent corrosion and is equipped with automatic temperature and liquid level controls to ensure a stable melting process.

- Conveying System: Consisting of a urea pump and pipelines, this system transports the molten urea from the melting tank to the granulation system. The pipelines are insulated with steam jackets to prevent the molten urea from solidifying and clogging them during transport. They are also equipped with steam purging devices to clear residual urea after shutdown.

- Granulation System: Examples include a rotary drum granulator, a pan granulator, or a high-tower granulation spray head. The drum and pan granulators form granules through the rolling and agglomeration of materials within the rotating drum or pan. The high-tower granulation spray head sprays the molten slurry from the top of a tower; as the slurry falls, it interacts with rising air currents, cooling and solidifying into granules.

- Drying System: A dryer, such as a rotary dryer, is typically used to dry the granulated material further, reducing its moisture content and improving granule stability and quality. Hot air is introduced into the dryer to exchange heat with the material, causing moisture to evaporate.

- Screening System: Composed of a trommel screen or vibrating screen, this system screens the dried granules to separate oversized and undersized particles that do not meet the required size. Oversized particles are crushed and returned to the granulation system, while undersized particles are also recycled back into the process to ensure uniform product granules.

III. Production Flow

- Urea Melting: Granular urea is fed into a melting tank and heated to 110-135°C (230-275°F) to melt into a liquid state. The concentration of the molten urea is kept at over 95% and the liquid level is maintained between 80-85%. The heating steam pressure is held at 0.5-1.2 Mpa.

- Material Mixing: The molten urea is transported by a pump to the granulator, where it is thoroughly mixed with pre-prepared fresh materials and recycled fines. Fresh materials typically include other fertilizer raw materials like ammonium phosphate and potassium chloride. Recycled fines are the small particles or powders from the previous production run that did not meet the size requirements. They are uniformly mixed with the molten urea in the granulator, forming material clumps with a certain viscosity and flowability.

- Granulation and Forming: Under the action of the granulator, the material clumps gradually form granules through rolling and agglomeration. In a rotary drum granulator, the material continuously tumbles and collides within the rotating drum, and the granules gradually grow and form due to the binding action of the molten urea. In high-tower granulation, the molten slurry is sprayed from a nozzle at the top of the tower, forming fine liquid jets that break into droplets upon contact with air. The droplets cool and solidify into granules as they fall.

- Drying and Screening: The granulated particles enter the dryer to be dried, reducing their moisture content to around 3%. The dried granules are then screened using a vibratory or trommel screen. Qualified granules proceed to the next stage, while non-conforming oversized and undersized granules are crushed and returned to the system for reprocessing.

- Cooling and Packaging: The screened, qualified granules enter a cooler to lower their temperature and increase their stability. The cooled granules are then ready for packaging and are stored in a warehouse as finished fertilizer products.

IV. Features of the Urea Melt Granulation Production Line

The urea melt granulation production line, as a key process in the fertilizer industry, has several significant features due to its unique technical principles and design.

- Simplified and Efficient Process Urea melt granulation eliminates the evaporation and crystallization pretreatment stages found in traditional granulation processes. The raw urea is directly melted into a liquid at a specific temperature and can then be fed directly into the granulation equipment. This streamlined process reduces the number of equipment units and production steps, lowering the probability of equipment failure and boosting overall production efficiency. It's ideal for large-scale, continuous, and stable production.

- Excellent and Stable Product Quality The urea granules produced by this method have good uniformity, a concentrated particle size distribution, and a smooth, rounded appearance. Because the urea molecules are more tightly arranged in their molten state, the resulting granules have high strength and are very resistant to breakage, caking, and powdering during storage, transport, and application. The ability to precisely control parameters like temperature and pressure during granulation also ensures the stability and consistency of the product's composition, meeting the needs of various agricultural applications.

- Low Energy Consumption and Environmental Friendliness Compared to traditional granulation processes, urea melt granulation does not require a large amount of energy for urea evaporation and crystallization. The main energy consumption is concentrated in the melting stage, where energy utilization is highly efficient. The process also generates less dust and waste gas, and effective exhaust treatment systems can control pollutant emissions. Additionally, water consumption is relatively low, which aligns with energy-saving and environmentally friendly production requirements, reducing environmental costs and pressure on the company.

- Strong Production Flexibility This production line has strong flexibility, allowing for easy adjustments to product parameters like particle size and nutrient content to meet different market and agricultural needs. By adding various types and proportions of micronutrients, slow/controlled-release agents, or other additives to the molten urea, it's possible to produce a diverse range of specialty fertilizers and compound fertilizers. This meets the specific fertilization needs of different soil conditions and crop types, broadening the product's application range.

- High Degree of Automation Modern urea melt granulation production lines typically use advanced automation control systems to provide real-time monitoring and precise regulation of key production parameters such as melting temperature, granulation speed, and material flow. The use of automation reduces manual intervention, minimizes the impact of human factors on product quality, and enhances production stability and reliability. It also enables real-time data collection and analysis, providing powerful support for production management and optimization.

- Good Raw Material Adaptability The production line has good adaptability to the purity and physical properties of the raw urea. It can process urea from different purities; as long as the raw urea purity meets a certain standard, it can be appropriately pretreated and then used for melt granulation. This reduces strict requirements for raw material supply, ensuring production continuity and stability, and minimizing the impact of fluctuations in raw material quality.

V. Application Fields of the Urea Melt Granulation Production Line

The urea melt granulation production line is a key process for turning raw urea into granular products. The resulting urea granules have advantages like high strength, uniform particle size, good slow-release properties, and resistance to caking, making them widely used in agriculture, industry, and ecological and environmental protection.

- Agricultural Planting Agriculture is the primary application field for this production line. Urea is a high-nitrogen fertilizer (with about 46% nitrogen) and an essential nutrient source for crop growth. Urea granules produced by melt granulation are widely used in agriculture:

- In grain crop cultivation (e.g., wheat, corn, rice), urea granules can be used as a base or top dressing fertilizer. Their uniformity ensures an even distribution of nutrients, preventing damage to roots from overly high local concentrations. Their high strength reduces breakage during transport and application, increasing fertilizer utilization.

- In economic crop cultivation (e.g., cotton, rapeseed, tobacco), which have a high demand for nitrogen, urea granules can meet the nutrient supply needs throughout their growth cycle. The slow-release effect of some melt-granulated urea can also be achieved through process adjustments, reducing the frequency of top dressing and lowering cultivation costs.

- In fruit and vegetable cultivation, urea granules can be applied by methods like trench or hole application. Slow-release urea granules can continuously provide nitrogen to fruit trees and vegetables, preventing excessive growth or quality decline due to a short-term oversupply of nitrogen, and helping to improve fruit and vegetable yield and quality.

- Compound Fertilizer Production The urea melt granulation production line plays an important role in compound fertilizer production. Compound fertilizers require mixing multiple nutrients like nitrogen, phosphorus, and potassium in a specific ratio to form granular products. Urea, as the main nitrogen source, can be uniformly mixed with other raw materials like ammonium phosphate, potassium chloride, and potassium sulfate in its molten state. The granulation equipment then forms compound fertilizer granules containing multiple nutrients.

- This process produces compound fertilizer granules with high strength and uniform nutrient distribution, meeting the combined nutrient needs of crops and saving farmers the trouble of applying multiple fertilizers separately.

- For example, in the production of specialty compound fertilizers for corn, the urea melt granulation process can integrate nitrogen, phosphorus, and potassium in an appropriate ratio, making the fertilizer better suited to the nutrient needs of corn growth and improving fertilization effectiveness.

- Industrial Production Urea granules produced by this line also have important applications in industry:

- In the production of wood-based panels, urea is one of the main raw materials for producing urea-formaldehyde resin. Melt-granulated urea has high purity and stable composition, which ensures the quality of the resin synthesis and, in turn, improves the bonding strength and stability of the wood-based panels.

- In power plants and industrial boiler denitrification, urea granules can be used as a reducing agent in Selective Catalytic Reduction (SCR) or Selective Non-Catalytic Reduction (SNCR) processes. Urea granules are dissolved to create a urea solution, which is then sprayed into the flue gas to react with nitrogen oxides, reducing their emission and meeting environmental requirements. The granular form of urea is easy to store, transport, and meter, ensuring a stable and efficient denitrification process.

- Ecological and Environmental Protection In this field, the slow-release urea granules produced by the line can be used for soil improvement and ecological restoration:

- In saline-alkali soil remediation, the proper application of urea granules can adjust soil pH, improve soil structure, and create a suitable environment for plant growth. The slow-release properties reduce nitrogen loss, preventing pollution of surrounding water bodies.

- In mine ecological restoration, urea granules serve as a nitrogen source for plant growth, promoting vegetation recovery. Their resistance to caking and slow-release characteristics can provide nutrients to vegetation over a longer period, improving plant survival rates.

In short, the urea melt granulation production line has irreplaceable value in agriculture, industry, and ecological and environmental protection due to the superior properties of its products. Its application scope will continue to expand as the technology is further optimized.

VI. Key Selection Criteria for a Urea Melt Granulation Production Line

Choosing a urea melt granulation production line directly affects product quality, production efficiency, operating costs, and environmental compliance. You need to comprehensively consider multiple factors like production needs, raw material characteristics, equipment performance, and environmental safety. Here are the key selection criteria:

- Define Production Needs and Scale Production scale is the fundamental prerequisite for selection. You must determine key metrics like annual capacity and daily output based on your company's medium- to long-term plans. For small to medium-sized companies with an annual capacity of 50,000-100,000 tons, a single medium-scale production line may be suitable. For large companies with an annual capacity of over 300,000 tons, you'll need to consider a combination of multiple lines or a large-scale integrated system. You also need to specify product specifications, such as particle size (typically 2-4.75mm), granule strength (≥2.5N), and moisture content (≤0.5%), as different specifications require different parameter settings for the granulation equipment.

- Analyze Raw Material Adaptability The purity, impurity content, and moisture of the raw urea directly affect the melting and granulation results. Raw urea purity should be above 99.5%. If the impurity content (e.g., biuret) is too high, it will increase the viscosity of the molten liquid, affecting the atomization. Raw material moisture should be controlled to below 0.3%; higher moisture will increase melting energy consumption and can cause the granules to cake during granulation. Therefore, when selecting a line, ensure the pretreatment system (e.g., screening, drying) is compatible with your raw material characteristics. You may need to configure raw material purification equipment if necessary.

- Evaluate Core Equipment Performance

- Melting System The melting system needs precise temperature control. The urea melting temperature should be stable at 132-138°C (270-280°F). Temperatures that are too high can cause urea decomposition (forming biuret and ammonia gas), which lowers product quality. Temperatures that are too low will result in incomplete melting and affect the uniformity of granulation. It's best to choose a melter that uses indirect heating (e.g., thermal oil heating) as it has smaller temperature fluctuations (within ±1°C) and introduces less moisture compared to direct steam heating. Also, check the melter's heat exchange efficiency to ensure heat utilization is over 85%.

- Granulation Equipment The granulator is the core of the production line. The main types include rotary drum granulators, spray granulation towers, and fluidized bed granulators. Your choice should depend on your product needs:

- Rotary drum granulators: Suitable for medium capacity, they produce highly rounded granules. The equipment investment is low, but energy consumption is higher, and granule strength uniformity is average.

- Spray granulation towers: Ideal for large-scale production. They produce uniform granules and have high production efficiency, but they require strict control over the molten liquid atomization and have higher maintenance costs.

- Fluidized bed granulators: Produce granules with high strength, have low energy consumption, and can operate continuously. However, they require strict control over operating parameters and are suited for high-quality product production. In addition, you should evaluate the performance of key components of the granulator, such as the atomization device (e.g., nozzle material, orifice size) and the stability of the transmission system (e.g., speed adjustment range).

- Match Product Quality Indicators The production line must ensure stable product quality. Pay close attention to these indicators:

- Particle Size Distribution: A passing rate of over 90% is required. When selecting, check if the granulator's classification and screening system can effectively control the particle size range.

- Granule Strength: This affects the product's transport and storage performance. You must ensure the strength meets standards through optimizing equipment parameters (e.g., cooling air volume, granulation speed).

- Biuret Content: This must be controlled to below 1.0%. This is directly related to the melting temperature control accuracy, so you should choose a melting system with intelligent temperature control and feedback adjustment.

- Control Energy Consumption and Operating Costs The line's energy consumption is mainly concentrated in melting, cooling, and power transmission. When selecting, compare the unit energy consumption of different equipment. For example, the comprehensive energy consumption per ton of product should be controlled within 80-120 kWh. Also, consider equipment maintenance costs, such as the replacement cycle and cost of wear parts (nozzles, transmission belts). It's best to choose equipment with long-lasting wear parts (e.g., nozzle lifespan of ≥3000 hours) and easy maintenance. You should also evaluate the equipment's operating efficiency, aiming for an uptime of over 90% to reduce unplanned downtime.

- Environmental and Safety Compliance Environmental and safety compliance are mandatory requirements for selecting a production line. The urea melting process generates a small amount of ammonia gas, so an efficient waste gas treatment system (e.g., a spray absorption tower) must be configured to ensure emissions comply with the "Integrated Emission Standard of Air Pollutants" (GB 16297). The equipment must also have complete safety protection facilities, such as thermal insulation for high-temperature equipment, emergency shutdown devices, and explosion-proof measures, in compliance with the "Safety and Health Design Standards for Chemical Enterprises" (HG 20571). The production line should also have a leak detection and alarm system to prevent safety risks from molten urea leaks.

- Equipment Stability and After-Sales Service Equipment stability directly affects production continuity. You should choose equipment made of high-quality materials (e.g., the melter made of 316L stainless steel) with a reasonable structural design to reduce equipment failure frequency. The supplier's after-sales service capability is also crucial. Investigate their technical support response time, spare parts supply capability, and the quality of their equipment installation, commissioning, and training services to ensure the line can be put into operation quickly and run stably. It's best to choose a supplier with a good reputation and rich experience in the industry.

- Automation and Intelligence Level A high level of automation can improve production efficiency and product quality stability. When selecting, consider the line's automated control system, which should be able to automatically adjust parameters like melting temperature, granulation speed, and cooling air volume, and should have data collection, remote monitoring, and fault diagnosis functions. An intelligent system can use data analysis to optimize production process parameters, reduce manual intervention, and improve the precision of production.

- Compatibility with Ancillary Facilities The production line must be compatible with ancillary facilities (e.g., raw material storage, finished product conveying, and packaging systems). Raw material storage silos need to have moisture-proof and anti-caking features. Finished product conveying equipment (e.g., belt conveyors, bucket elevators) should prevent damage to the granules. The packaging system must match the granule specifications, ensuring accurate measurement and good package sealing. When selecting, you should plan the entire system to ensure a smooth transition between all stages and prevent a loss of production efficiency due to incompatible ancillary facilities.

In summary, the selection of a urea melt granulation production line is a systematic process. You must comprehensively weigh production needs, technical performance, economic costs, environmental safety, and other factors. By combining these with your company's actual situation and industry development trends, you can choose a line that has a high cost-performance ratio and strong adaptability, laying the foundation for efficient, stable, and environmentally friendly production.

Tai'an Hongxin Environmental:

Supply of High-Quality and Efficient Fertilizer Production Equipment, Straw Processing Equipment, Waste Treatment Equipment and Mining Equipment. If you are looking for fertilizer production equipment and production lines, feel free to contact us at any time.- Whatsapp(Tel): + 86 139-0548-5429( Mr. Li)

- E-mail: tahongxin@gmail.com