Description

The compound fertilizer drum granulation production line is a widely used equipment for producing compound fertilizers. The following will provide an introduction to its process flow, equipment composition, process characteristics, and other aspects:

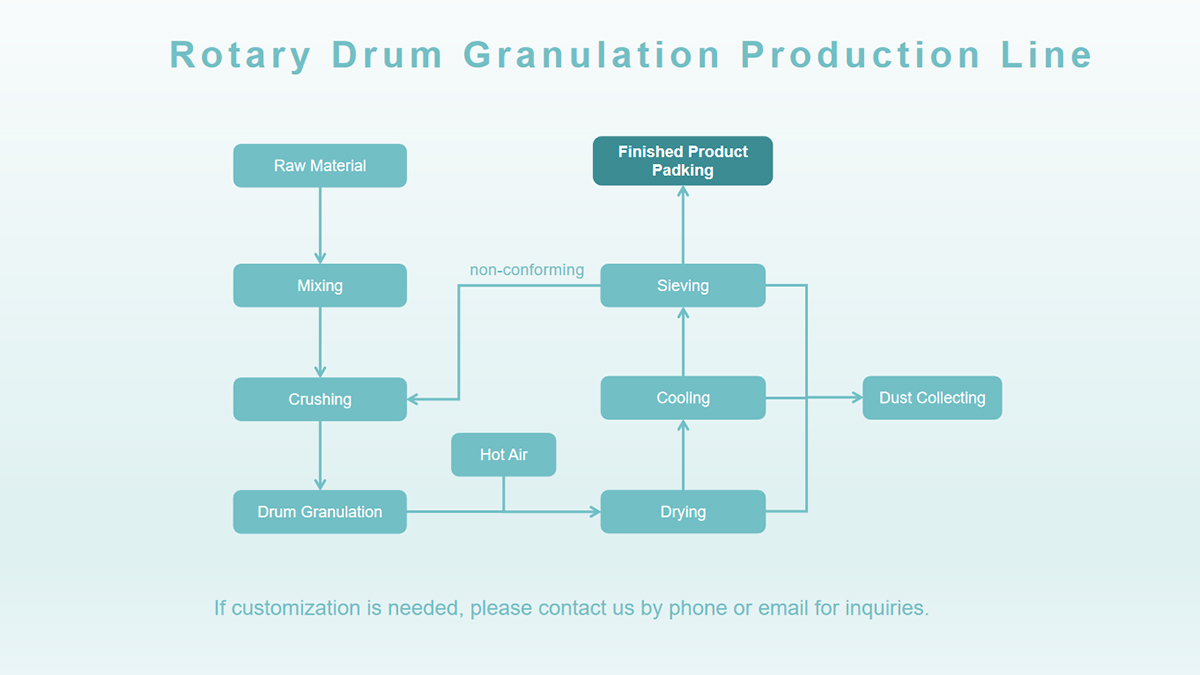

1. Process Flow

- Raw Material Pre-treatment: Required basic fertilizer raw materials such as nitrogen, phosphorus, and potassium, along with other additives, are crushed and mixed to ensure uniform particle size and composition. This provides a good foundation for subsequent granulation.

- Drum Granulation: While the pre-treated raw materials are transported into the granulator, a certain amount of water or steam is added through pipelines to humidify the materials, bringing them to the optimal moisture content for granulation. This increases the material's viscosity and promotes the formation of granules. The drum granulator is an inclined cylinder with a special internal structure, such as an acid and alkali-resistant rubber lining. As the cylinder rotates, the materials continuously tumble, rub, and compress inside, gradually forming granules. The balling rate can reach about 70%, and the small-sized return materials can be re-granulated.

- Drying the Granules: The granulated wet particles contain a high moisture content and need to be dried by a drying machine to reduce their moisture to the specified level. This enhances the granules' stability and storage properties, preventing caking and deterioration.

- Cooling the Granules: The dried granules are transported to a cooler to lower their temperature, which further increases their hardness and stability, preventing them from cracking during storage and transportation due to temperature changes.

- Granule Screening: A screening machine is used to separate particles that do not meet the standard size, ensuring a uniform particle size for the final product to meet market demands. Large-sized particles that do not meet the requirements can be crushed and returned to the granulator with small-sized particles for re-granulation.

- Finished Product Packaging: The screened finished granules are packed for storage. Moisture-proof and damage-resistant packaging materials are selected to ensure the safety and quality of the product during storage and transportation.

2. Equipment Composition

- Automatic Batching System: Mainly composed of a feeding system, weighing device, silo, and conveyor belt, it enables precise batching to ensure accurate raw material proportions.

- Belt Conveyor: Used for transporting raw materials and semi-finished products. There are various types, such as mobile lifting and fixed types, which increase the mobility and flexibility of the equipment and allow for material transport according to site conditions.

- Disc Mixer: Consists of a mixing pan, discharge port, mixing arm, frame, gearbox, and transmission mechanism. It ensures thorough mixing of materials and uniform distribution of each component.

- Drum Granulator: The core equipment. It uses the rotation of the cylinder and a special internal structure to agglomerate materials into balls. It features a high balling rate, good appearance quality, and resistance to corrosion and wear.

- Drying Machine: Typically a rotary drum dryer, used for drying wet granules. It has advantages such as simple operation, uniform drying, and convenient maintenance, effectively reducing the moisture content of the granules.

- Rotary Screen: A common device in compound fertilizer production, mainly used for separating finished products from return materials. It can also classify products, ensuring uniform classification of finished products. It uses a combination of screen meshes for easy maintenance and replacement.

- Coating Machine: A complete set of rotary coating equipment consists of a screw conveyor, mixing tank, oil pump, main machine, and transmission device. Through powder dusting or liquid coating processes, it can effectively prevent caking of compound fertilizers and improve product quality.

- Packaging Scale: Can be divided into semi-automatic and fully automatic packaging scales. It mainly consists of an automatic quantitative packaging scale and optional components, used for weighing and packaging finished granules to achieve quantitative packaging and warehousing.

3. Characteristics of Compound Fertilizer Drum Granulation Production Line

The compound fertilizer drum granulation production line is a widely used process equipment in the fertilizer production industry. Its core characteristics are reflected in strong process adaptability, production stability, product quality control, and comprehensive economic benefits, as detailed below:

- Strong Process Adaptability and Wide Raw Material Compatibility The drum granulation process has high compatibility with the physical and chemical properties of raw materials. It can handle basic fertilizer raw materials like nitrogen, phosphorus, and potassium (e.g., urea, ammonium chloride, monoammonium phosphate, potassium chloride), as well as functional raw materials such as organic fertilizers, humic acid, and trace elements. Whether it's solid powder, granular material, or semi-solid material with a certain moisture content, they can be incorporated into the production process through reasonable proportioning and pre-treatment. This is especially suitable for producing multi-functional compound fertilizers with flexible formulas to meet the personalized needs of different crops and soils.

- Stable and Continuous Production, Flexible Scale Adjustment The production line uses a drum as the core granulation equipment, achieving granulation through the continuous tumbling and adhesion of materials inside the drum. It is complemented by a front-end raw material metering and mixing system and a back-end drying, cooling, and screening process, forming a closed-loop continuous production flow. The capacity of a single production line can be flexibly designed according to demand, from small and medium-sized scales with an annual output of tens of thousands of tons to large-scale production lines of several hundred thousand tons. The process parameters are also easily adjustable during production, allowing for a long-term stable output.

- Controllable Product Quality and Excellent Granule Performance Compound fertilizer granules produced by drum granulation have the following advantages: First, high granule uniformity. By adjusting the drum's rotation speed, tilt angle, and material moisture, the particle size can be precisely controlled (usually in the range of 2 - 4.75mm), with a qualification rate of over 90%. Second, good granule strength. The granules formed by rolling and compaction have a dense structure and strong resistance to crushing, making them less prone to caking or pulverization during storage, transportation, and application. Third, uniform nutrient distribution. Raw materials are thoroughly mixed during the mixing stage, and nutrient encapsulation is further achieved during the granulation process, ensuring consistent nutrient content in every granule.

- Lower Energy Consumption and Favorable Overall Economics Compared to processes like spray granulation and high-tower granulation, the drum granulation production line has a lower equipment investment cost, making it especially suitable for small and medium-sized enterprises' initial investment. In terms of energy consumption, the main energy consumption is concentrated in the drying stage. By optimizing the hot air circulation system and waste heat recovery devices, the unit product energy consumption can be effectively reduced. Furthermore, the production line's raw material pre-treatment requirements are relatively lenient, without the need for complex melting or atomization equipment, which further reduces production and maintenance costs.

- Simple Operation and Maintenance, High Equipment Reliability The drum granulation equipment has a relatively simple structure. The core component, the drum, uses wear-resistant lining plates (such as rubber or cast stone linings) with a long service life and low failure rate. The operation of the production line can be automated through a PLC control system, allowing operators to master parameter settings and daily monitoring after simple training. Equipment maintenance focuses on key components such as the drum transmission system and screening equipment. The maintenance process is standardized, and spare parts are easy to replace, effectively reducing downtime.

- Optimizable Environmental Performance, Meeting Green Production Demands Modern drum granulation production lines can integrate dust collection devices (such as pulse dust collectors) and tail gas purification systems to effectively treat the dust and waste gas generated during production, reducing pollutant emissions. Simultaneously, the water circulation system of the production line can achieve cooling water reuse, reducing water consumption and aligning with the green and low-carbon development trend of the fertilizer industry.

- Upgradable Automation Level for Improved Production Precision With the application of intelligent manufacturing technologies, the drum granulation production line can be equipped with online detection devices (such as near-infrared analyzers and particle size detectors) to monitor key indicators like raw material ratio and granule quality in real time. Through an automatic feedback system, it can adjust metering and granulation parameters to achieve precise control of the entire process, further improving product stability and qualification rates.

In conclusion, the compound fertilizer drum granulation production line has become a mainstream process choice for compound fertilizer production due to its strong adaptability, stable and efficient performance, and controllable costs. It shows significant advantages, especially in scenarios with multiple formulas and medium-to-low capacity needs, providing strong support for the large-scale and refined development of the fertilizer industry.

4. Application Fields of Compound Fertilizer Drum Granulation Production Line

With its strong continuous production capacity, stable granule quality, and wide raw material adaptability, the compound fertilizer drum granulation production line is widely used in agriculture and related fields, mainly covering the following scenarios:

- Field Crop Cultivation In the large-scale cultivation of field crops such as wheat, corn, rice, and soybeans, the drum granulation production line plays a core role. These crops require large amounts of fertilizer and balanced nutrients. The production line can adjust the ratio of nitrogen, phosphorus, potassium, and micro- and macro-elements to produce general-purpose or specialized compound fertilizers that meet the needs of different crop growth stages. For example, for the high potassium demand during the jointing stage of corn, a high-potassium formula granular fertilizer can be customized. For rice cultivation, specialized fertilizers containing elements like silicon and zinc can be produced to enhance the crop's lodging resistance and yield. Its stable capacity (a single production line can produce tens to hundreds of tons per day) can meet the fertilization needs of large-scale farmland.

- Economic Crop Cultivation Economic crops such as vegetables, fruit trees, and flowers have higher demands for fertilizer precision and functionality. The drum granulation production line can develop targeted special fertilizers. For vegetable cultivation, compound fertilizers for crops like tomatoes and cucumbers require a balance of NPK and the addition of calcium and magnesium. The production line can control granule hardness and slow-release properties to reduce the frequency of top-dressing. For fruit tree cultivation, to meet the long nutrient demand cycle of apples and citrus, slow/controlled-release compound fertilizers can be produced, using the coating process inside the drum to achieve slow nutrient release, preventing root burn and nutrient loss. For flower cultivation, low-salt formula granular fertilizers can be produced to meet the gentle fertility needs of potted flowers.

- Forestry and Ecological Greening In afforestation, economic forest cultivation, and urban greening, compound fertilizers produced by the drum granulation production line can provide long-term nutrient support. In the cultivation of fast-growing trees (e.g., poplar, eucalyptus), high-nitrogen and high-phosphorus formula granular fertilizers can promote rapid tree growth. Economic forests (e.g., walnut, chestnut) need nutrient supply during the flowering and fruiting periods; the production line can produce compound granular fertilizers containing humic acid to improve fruit quality. In urban greening, for the growth characteristics of lawns and street trees, compound fertilizers with strong stress resistance can be produced. The uniformity of the granules ensures consistent growth of greening plants after fertilization, reducing maintenance costs.

- Soil Improvement and Special Planting In soil improvement projects for saline-alkali land and barren soil, the drum granulation production line can produce functional compound fertilizers. By adding soil conditioners like desulfurized gypsum and humic acid, the conditioning components are combined with the nutrient granules, improving soil structure while supplementing fertility. In facility agriculture (e.g., greenhouses), for soil compaction issues caused by continuous cropping, compound granular fertilizers containing biological agents can be produced. The gentle process of drum granulation protects the activity of the microbial agents. Furthermore, in special planting fields like traditional Chinese medicinal herbs and tea, compound fertilizers that meet organic farming standards can be produced, meeting the fertilizer needs of green agriculture through natural raw material proportioning and granulation technology.

- Large-scale and Modern Agricultural Parks Modern agricultural parks and planting cooperatives rely on drum granulation production lines to achieve self-sufficiency in fertilizers or customized supply. The production line can be combined with soil testing and fertilizer formulation technology to adjust the formula in real time based on soil test data, producing "one-soil-one-policy" specialized fertilizers. At the same time, its automated control system (e.g., intelligent control of batching, granulation, and drying) ensures stable fertilizer quality and is compatible with the spreading needs of large-scale fertilization machinery, improving the intensive level of agricultural production.

In summary, the compound fertilizer drum granulation production line has become a key link connecting fertilizer production with various planting scenarios through its flexible formula adjustment capabilities, stable granule quality, and large-scale production efficiency, supporting the precise fertilization and efficient development of modern agriculture.

5. Key Selection Points for Compound Fertilizer Drum Granulation Production Line

In the process of compound fertilizer production, the selection of a drum granulation production line is crucial, as it directly affects production efficiency, product quality, operating costs, and environmental compliance. The following will discuss key selection points from several critical dimensions to provide a reference for business decisions.

- Matching Production Needs Production needs are the primary basis for selection. It is necessary to comprehensively consider production capacity, raw material characteristics, and product specifications. For production capacity, a reasonable capacity should be determined based on the company's medium-to-long-term development plan. A small production line (annual output of 10,000 - 50,000 tons) is suitable for startups or scenarios with low regional market demand, where the drum diameter is usually 1.2 - 2 meters and the length is 3 - 6 meters. A medium-sized production line (annual output of 100,000 - 300,000 tons) is suitable for medium-sized enterprises, with a drum diameter of 2 - 3 meters and a length of 6 - 10 meters. A large-scale production line (annual output of 500,000 tons or more) requires a drum diameter of 3 meters or more and a length of 10 meters or more, and the stability of continuous production must be considered. Raw material characteristics significantly affect equipment selection. The physical and chemical properties of different raw materials vary greatly, such as urea's high moisture absorption, ammonium chloride's strong corrosiveness, and high hardness of phosphate rock powder. If the raw material moisture is high (over 15%), an efficient drying pre-treatment equipment is needed. Raw materials containing corrosive components require the use of corrosion-resistant materials (e.g., 316L stainless steel) for the drum lining. High-hardness raw materials require the internal flighting boards of the drum to be wear-resistant (e.g., using wear-resistant cast iron or hardfacing layers). For product specifications, it is necessary to clarify the NPK ratio, granule particle size (usually 2 - 4.75mm), and compressive strength (generally required to be ≥ 2.5N) of the fertilizer. For compound fertilizers containing trace elements or functional additives, the uniformity of raw material mixing needs to be considered, and a pre-mixing device may need to be added before the drum. For products requiring high granule sphericity, the drum rotation speed and internal structure design need to be optimized.

- Consideration of Core Equipment Performance The drum granulator is the core equipment, and its performance directly determines the granulation effect. Key attention should be paid to specifications, transmission system, and internal structure. Among the specifications, the length-to-diameter ratio is a key indicator, usually controlled between 3 and 5. A ratio that is too small will result in insufficient material retention time and incomplete granulation; a ratio that is too large can lead to increased energy consumption and a larger equipment footprint. The drum rotation speed needs to match the raw material characteristics, typically 5 - 15 r/min. A speed that is too high can cause granule breakage, while a speed that is too low can result in low granulation efficiency. The transmission system must be stable and reliable. It is recommended to choose a hard-tooth surface reducer with a variable-frequency motor to achieve stepless speed regulation, adapting to the granulation needs of different raw materials and products. At the same time, the transmission components must have sufficient load capacity to avoid shutdown due to overload. The internal structure design is crucial for granulation uniformity. The form of the flighting boards should be selected based on the material's fluidity. For viscous materials, inclined flighting boards can be used to enhance material tumbling. For materials with good fluidity, curved flighting boards can be used to reduce material sliding. The material of the drum lining should be selected based on the raw material characteristics. For ordinary compound fertilizers, Q235B steel plate lined with PVC board can be used, while corrosive raw materials require stainless steel lining.

- Synergy of Supporting Systems A drum granulation production line is an integrated system composed of multiple sub-systems. The synergy of the supporting systems directly affects overall efficiency. The raw material pre-treatment system must ensure the raw material particle size is qualified (generally requiring 90% to pass through an 80-mesh sieve). Corresponding crushing equipment (e.g., cage crushers, hammer crushers) and screening equipment (e.g., vibratory screens) must be configured. The selection of crushing equipment should be determined based on raw material hardness. Hard raw materials require impact crushers, while viscous materials need crushers with self-cleaning functions. The heating and drying system needs to determine the heat source type and drying efficiency based on capacity and raw material moisture. Heat sources can include steam, hot air furnaces (coal, gas, or biomass). In regions with strict environmental requirements, natural gas hot air furnaces are recommended. The processing capacity of the drying equipment (e.g., rotary dryer) must match the drum granulator to ensure wet granules are dried in a timely manner to a moisture content of ≤2%. In the cooling and screening system, the cooling efficiency of the cooling equipment (e.g., cooling drum) must ensure that the granule temperature is reduced to ambient temperature ±5°C to prevent caking during subsequent storage. The screening equipment must have a multi-stage screening function to separate unqualified fines and oversized particles and return them to the system for re-granulation. The screening accuracy must reach over 95%.

- Energy Consumption and Operating Cost Control During the selection process, it is necessary to comprehensively evaluate energy consumption, consumable life, and labor requirements to reduce long-term operating costs. In terms of energy consumption, the power of the drum motor and the energy consumption of the drying system are the main components. It is necessary to compare the unit product energy consumption indicators of different equipment, such as electricity consumption per ton of product (generally required to be ≤50kWh) and coal consumption (generally required to be ≤80kg of standard coal). Using energy-saving equipment such as variable-frequency motors and high-efficiency heat exchangers can significantly reduce energy consumption. The life of consumables directly affects maintenance costs. Wear-resistant and corrosion-resistant materials should be selected for the drum lining, flighting boards, and vulnerable parts of the crushing equipment to extend their replacement cycle. For example, if the drum lining uses ultra-high molecular weight polyethylene board, the service life can be 1 - 2 years. Hammerheads of crushing equipment made of bimetallic composite materials have a lifespan that is more than 30% longer than ordinary materials. For labor requirements, give priority to production lines with a high degree of automation. A PLC control system can automate operations such as raw material proportioning, speed regulation, and temperature control, reducing manual intervention. An automated production line can reduce the number of operators by more than 50% while improving production stability.

- Environmental and Safety Compliance With increasingly strict environmental requirements, the production line must meet environmental emission standards and safety regulations. Dust treatment requires the configuration of high-efficiency dust collection equipment, such as bag filters, with a dust collection efficiency of over 99.9%, ensuring the workshop dust concentration is ≤10mg/m³. Sealing devices should be installed at raw material conveying, crushing, and screening points to reduce dust overflow. For tail gas treatment, the tail gas discharged from the drying system must be treated for desulfurization, denitrification, and dust removal to meet relevant standards such as the "Emission Standard of Pollutants for Synthetic Ammonia Industry" (GB13458 - 2013). Using low-NOx burners can reduce nitrogen oxide emissions and lower tail gas treatment costs. Safety protection must comply with the "General Principles for Safety of Machinery" (GB/T15706 - 2012). Equipment should be equipped with emergency stop buttons and overload protection devices, and rotating parts like the drum should have protective covers installed. For production lines involving flammable raw materials, explosion-proof equipment and a fire fighting system are necessary.

- Supplier Strength and Service Assurance Choosing a capable supplier can reduce equipment quality risks and ensure subsequent service support. Examine the supplier's technical expertise and manufacturing capabilities, and prioritize companies with more than 10 years of industry experience and independent R&D capabilities. Review their past cases, especially the operation of projects similar in scale and raw material type, to understand the actual performance of the equipment. After-sales service is a key consideration. The supplier must provide full-cycle services including installation, commissioning, personnel training, and spare parts supply. Clarify the after-sales service response time (e.g., on-site within 24 hours) and spare parts supply cycle (regular parts ≤72 hours) to ensure timely repair of production line failures. Customization capability is also crucial, as different companies have different needs for raw materials and products. The supplier must be able to optimize the equipment design based on actual needs, such as adjusting the granulation process for special raw materials or customizing the layout of the production line.

- Technological Maturity and Upgrade Potential Prioritize production lines with mature technology to reduce trial-and-error costs. Mature technology has been validated by the market for a long time, and its operational stability and product quality are more assured, avoiding the use of new technologies that are still in the experimental stage. At the same time, it is necessary to consider the upgrade potential of the production line. As the company develops, there may be a need to increase capacity or expand product types. The equipment must have room for modification, such as pre-reserved interfaces for lengthening the drum, support for function expansion of the control system, and modular upgrades for supporting equipment, to extend the service life of the production line.

In summary, the selection of a compound fertilizer drum granulation production line requires a comprehensive consideration of production needs, equipment performance, cost control, environmental and safety compliance, and supplier services. A thorough evaluation can achieve efficient, stable, economical, and compliant operation of the production line, creating long-term value for the company.

Tai'an Hongxin Environmental:

Supply of High-Quality and Efficient Fertilizer Production Equipment, Straw Processing Equipment, Waste Treatment Equipment and Mining Equipment. If you are looking for fertilizer production equipment and production lines, feel free to contact us at any time.- Whatsapp(Tel): + 86 139-0548-5429( Mr. Li)

- E-mail: tahongxin@gmail.com