Description

A resin-coated fertilizer granule production line is a system of equipment used to apply a resin coating to fertilizer granules, achieving a slow- and controlled-release effect. Here is a detailed introduction to its process.

I. Working Principle

The process uses a high-molecular-weight resin with a very low water permeability as the coating material. This resin is uniformly applied to the surface of the fertilizer granules, forming a thin resin membrane with low water dialysis properties. When the fertilizer is in the soil, water permeates the resin membrane and dissolves the nutrients inside the granule. These nutrients then slowly pass through the membrane for absorption by crops. By controlling the rate at which the nutrients dissolve and pass through the membrane, the line achieves a slow- and controlled-release effect.

II. Main Components

- Feeding System: This typically consists of a feed hopper and a belt conveyor. The hopper stores the fertilizer granules to be coated, and the belt conveyor transports them to the coating equipment. It can control the feed speed and flow rate to ensure a continuous coating process.

- Coating Material Dissolving Device: This includes a dissolving tank and a mixing tank. The resin and other coating materials are added to the tank, and through heating and mixing, they are dissolved in an organic solvent to form a resin coating solution.

III. Coating Equipment

- Coating Machine: This machine takes the resin coating material, which has been heated and melted in the mixing tank, and sprays it onto the granular fertilizer. Inert powders are also metered and fed into the coating machine by a screw conveyor.

- Discharging System: Located at the end of the final coating machine and connected to its outlet, this system typically includes a discharge pipe and a rotary valve. It is used to discharge the resin-coated fertilizer granules from the production line, after which the finished product goes to the packaging system.

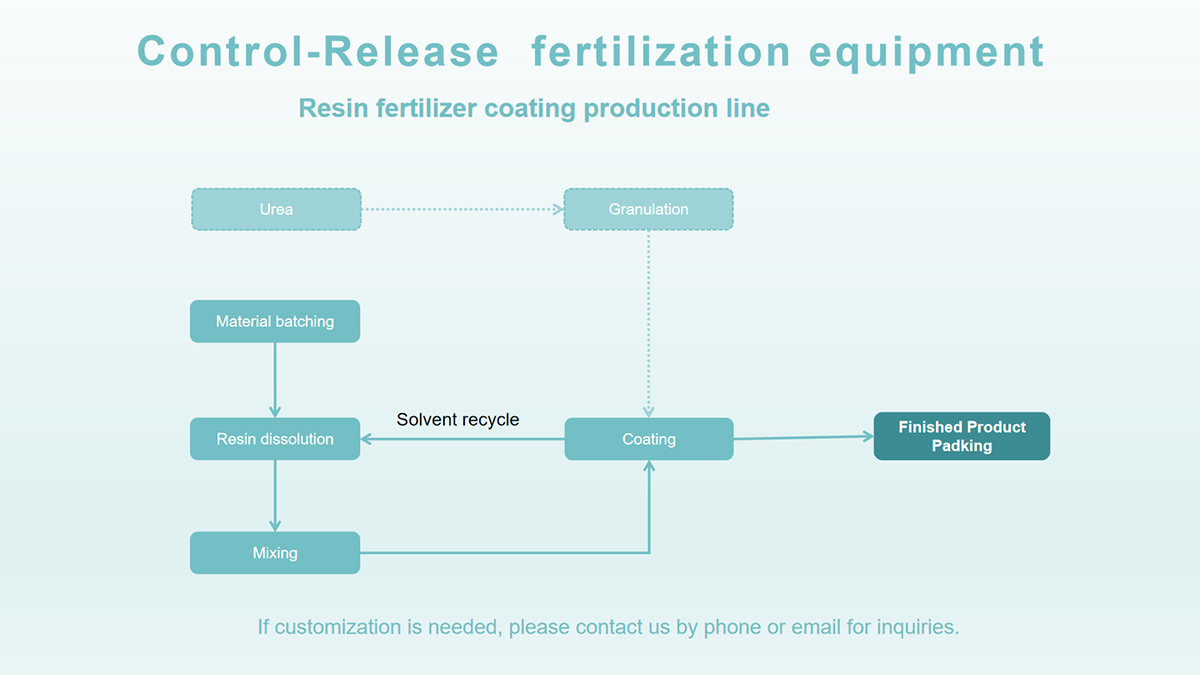

IV. Production Flow

- Coating Material Preparation: An organic solvent is added to a dissolving tank, followed by a measured amount of coating material. A mixer is started, and the temperature is controlled at 125-135°C (257-275°F) to dissolve the resin material and create a refined resin coating solution.

- Feeding: An upstream elevator or belt conveyor transports the granular fertilizer into the coating machine.

- Coating: The resin coating solution is sprayed from a nozzle through a pipeline, uniformly coating the surface of the fertilizer granules to form a resin membrane. The granules rotate inside the coating machine, ensuring the resin is applied evenly to their surface.

- Discharging: The finished coated granules are discharged from the end of the coating machine and are transported by an elevator or belt conveyor to the finished product warehouse for packaging.

V. Features

A resin coating production line is a professional equipment system for applying a resin coating to the surface of granular materials (such as fertilizers, seeds, and chemical granules). Its features are primarily reflected in its advanced technology, production efficiency, adaptability, and environmental friendliness.

- High Coating Uniformity, Stable Product Quality The production line uses advanced coating technology (such as fluidized bed coating, spray coating, etc.). It precisely controls the fluidization state of the material, the amount of resin sprayed, and the atomization effect to ensure the resin coating is uniformly distributed on the granule surface. It is also equipped with a closed-loop temperature and humidity control system to prevent uneven coating thickness caused by localized parameter fluctuations. This ensures consistent coating quality for every batch of product, effectively improving the slow-release performance, moisture resistance, or stability of the products.

- High Degree of Automation, Excellent Production Efficiency The production line integrates a smart PLC control system to automate the entire process, from raw material transport and coating to drying, curing, and finished product screening. A human-machine interface allows for real-time monitoring of production parameters (e.g., rotation speed, temperature, flow rate) and supports parameter presets and automatic adjustments, which reduces errors from manual intervention. The continuous production design significantly increases the output per unit of time, making it suitable for large-scale industrial production needs and lowering labor costs per unit of product.

- Strong Material Adaptability, Flexible Process Adjustment The line can handle granular materials with different particle sizes (typically 0.5-5mm) and densities. By adjusting parameters like conveying speed, mixing intensity, and spray pressure, it can meet the coating needs of various products. For different types of resin materials (e.g., thermosetting resins, slow-release resins), the line can flexibly switch process conditions, such as heating methods and drying times, to precisely control performance like coating hardness and adhesion. This expands its application scenarios (e.g., agricultural slow-release fertilizers, industrial wear-resistant granules, etc.).

- Eco-Friendly and Energy-Saving Design, Compliant with Green Production Standards The line uses a closed production process and is equipped with efficient dust collection devices (like pulse dust collectors) to reduce the pollution of the workshop environment from resin volatiles and dust. The drying system uses a waste heat recovery technology to reuse the heat from the exhaust gas, reducing energy consumption. Some equipment is made of corrosion-resistant materials (like 304 stainless steel) to reduce resin residue and corrosion, and it's easy to clean and maintain, which aligns with environmental regulations and green production requirements.

- Smart Monitoring and Convenient Maintenance The production line has a built-in sensor network that can collect real-time data on equipment status (e.g., motor current, bearing temperature). A smart diagnostic system can then predict potential faults, reducing the risk of downtime. Key components (like nozzles and filters) are designed with a quick-release structure for easy daily cleaning and replacement, which reduces maintenance time. The system also supports the storage and traceability of production data, providing support for quality analysis and process optimization.

- High Equipment Durability, Stable and Reliable Operation Core components (e.g., fluidized bed chamber, conveying screw, spray system) are made of high-strength, wear-resistant materials to withstand the wear and tear of long-term, high-frequency production. The overall structure of the equipment is optimized for mechanics, which reduces vibration and noise and lowers the failure rate during operation. A complete set of safety protection devices (e.g., overload protection, emergency stop system) ensures the safety of the production process, extends the equipment's service life, and guarantees long-term stable operation.

VI. Application Fields of Resin Coating Production Lines

A resin coating production line, by uniformly coating a substrate with resin material, gives the product special properties such as corrosion resistance, wear resistance, insulation, and weather resistance. It is widely used in various industrial and consumer sectors. Here are its main application scenarios:

- Construction and Building Materials: In the construction industry, the line is often used for surface treatment of metal profiles and sheets. For example, aluminum alloy profiles for building doors and windows and steel plates for curtain walls, when coated with epoxy or polyurethane resin, can have their resistance to acid and alkali corrosion significantly improved, extending their service life by 15-20 years. Additionally, resin-coated light steel keels and ceiling brackets used for interior decoration can effectively prevent rust in humid environments.

- Automotive and Transportation: Metal parts of an automobile chassis (e.g., suspension arms, drive shafts) can form a wear-resistant and anti-corrosion layer through resin coating, reducing damage from road debris and rainwater erosion. The battery casings of new energy vehicles, when coated with modified resin, can achieve insulation, fire resistance, and anti-corrosion functions simultaneously. In rail transit, high-speed train car aluminum alloy frames can be coated with fluorocarbon resin to resist airflow erosion and UV aging during high-speed travel.

- Electronics and Electrical Appliances: The wire and cable industry is a major application of this production line. By coating copper or aluminum core wires with polyvinyl chloride (PVC) or cross-linked polyethylene resin, an insulating layer and a protective sheath are formed, ensuring the wire's electrical insulation performance and mechanical strength. The casings of electronic components (e.g., connectors, relay casings) can be coated with epoxy resin to improve moisture resistance, dust resistance, and high/low-temperature resistance, ensuring stable operation of electronic devices in complex environments.

- Medical Devices: The metal handles of surgical instruments can be coated with medical-grade epoxy resin to form a smooth and biocompatible surface. This makes them easy to clean and sterilize and prevents metal ions from leaching out and irritating human tissue. Metal brackets in rehabilitation devices (e.g., wheelchair frames), when coated with antibacterial resin, can reduce bacterial growth during long-term use and lower the risk of cross-infection.

- Pipeline Engineering: Metal pipes for water and gas transportation can be coated with resin powder (e.g., polyethylene powder spraying) to form a continuous and dense anti-corrosion layer, which is particularly suitable for protecting buried pipes from soil corrosion. Acid and alkali conveying pipes in the chemical industry can be coated with polytetrafluoroethylene (PTFE) resin to withstand long-term erosion from strong corrosive media, ensuring the safe and stable production of chemicals.

- Agriculture and New Energy: Agricultural irrigation pipes can be coated with UV-cured resin to resist sunlight exposure and soil microbial erosion in the field, extending their service life. In the photovoltaic industry, the metal components of solar brackets can be coated with resin to improve their resistance to wind erosion and salt spray in harsh outdoor environments, ensuring the long-term power generation efficiency of photovoltaic power plants.

- Packaging Industry: The inner wall of metal cans for food packaging (e.g., beverage cans) can be coated with food-grade epoxy resin to prevent the contents from reacting with the metal, ensuring food safety. Steel drums for industrial packaging can be coated with resin to improve their leak-proof performance for chemicals like engine oil and paint. The resin coating production line, with its advantages of continuous and automated production, can adjust the resin type, coating thickness, and curing process according to the needs of different industries, providing customized surface function solutions for various products and serving as a key technical asset for improving product performance in modern industry.

VII. Key Selection Criteria for a Resin Coating Production Line

When choosing a resin coating production line, you need to consider multiple factors to ensure the line can meet production needs, guarantee product quality, lower operating costs, and comply with industry standards. Here are the key selection criteria:

- Material Adaptability Different materials have unique characteristics, such as particle size, hardness, and moisture, which directly affect the coating result. Therefore, the production line must be compatible with your target material. For materials that require fine spray, you should focus on the spray system's atomization effect and spray uniformity. For materials that need gentle drying, you should pay attention to the drying system's temperature control accuracy and drying efficiency to prevent the material from being damaged by over-drying or under-drying.

- Core Performance Parameters The performance parameters of the production line's core components are critical, as they directly determine the coating quality and production efficiency. The adjustable range of the coating pan's rotation speed and tilt angle should meet the coating needs of different materials, ensuring the material can roll and mix thoroughly in the pan. The spray system's spray volume and pressure adjustment accuracy must meet standards to ensure uniform coating film thickness. The drying system's heating power, hot air volume, and temperature range must be precisely controllable to achieve fast and uniform drying.

- Production Efficiency The production line's capacity must match your company's production needs to avoid insufficient or excessive capacity. At the same time, you should focus on the line's continuous production capability, checking whether it's equipped with automated feeding and discharging systems to reduce manual intervention, improve production continuity and efficiency, and lower labor costs. In addition, the stability of the equipment's operating speed and its ability to switch products quickly will also affect overall production efficiency.

- Quality Control Capability The uniformity of the coating and the consistency of the film thickness are core quality indicators. Therefore, the production line must have good quality control capabilities. The temperature control accuracy should meet a high standard to ensure temperature stability during the coating process, which prevents a decline in coating quality due to temperature fluctuations. Spray uniformity can be monitored with online detection equipment, such as infrared thermometers and particle size monitors, to get real-time information on the coating status and adjust parameters in time. The production line should also have data recording and traceability functions to facilitate the analysis and tracing of quality issues.

- Energy Consumption and Environmental Compliance In modern production, energy consumption and environmental protection are important considerations. You should compare the energy consumption of different heating methods (electric, steam, hot air) and choose an energy-efficient and eco-friendly one. The production line should be equipped with a comprehensive waste gas treatment system to ensure emissions comply with environmental standards. In addition, the equipment's noise level should also meet standards to reduce its impact on the production environment and operators.

- Equipment Stability and After-Sales Service The stability and reliability of the equipment are directly related to the production line's service life and maintenance costs. The materials of key components should be corrosion-resistant and high-temperature resistant to adapt to the harsh environment of resin coating production. Choose a reputable brand supplier whose equipment quality is more guaranteed. The supplier should also provide timely after-sales service, including installation, debugging, technical support, and fault repair, and an adequate supply of spare parts to reduce equipment downtime.

- Automation and Compliance With the development of smart manufacturing, the level of a production line's automation is becoming increasingly important. The control system should be user-friendly and intuitive, with functions like parameter storage, recall, and remote monitoring to facilitate standardized management of the production process. For industries like pharmaceuticals and food, the production line must comply with relevant industry standards, such as GMP certification for the pharmaceutical industry and hygiene standards for the food industry, to ensure the compliance of the production process.

- Cost and Scalability When choosing a production line, you shouldn't just focus on the initial purchase cost. You also need to comprehensively consider operating costs (energy, consumables) and maintenance costs. At the same time, consider whether the production line has the potential for upgrades and expansion to adapt to future increases in capacity or product upgrades, which will prevent the need for a complete equipment replacement due to insufficient capacity or outdated features, thereby increasing company costs.

- Site Adaptability The production line's footprint should be compatible with your factory space, and the layout should be flexible to allow for the optimization of the production process and equipment maintenance. You also need to consider whether the production line requires special installation conditions, such as a clean room or explosion-proof requirements, to ensure it can be installed and operated smoothly.

- Test Verification Before formally choosing a production line, you should conduct a small-scale or pilot-scale test to verify the line's coating effect on your target material. Through testing, you can understand the line's actual performance, coating quality, and production efficiency, ensuring the equipment can meet your expected quality indicators and production requirements and reducing investment risk.

Tai'an Hongxin Environmental:

Supply of High-Quality and Efficient Fertilizer Production Equipment, Straw Processing Equipment, Waste Treatment Equipment and Mining Equipment. If you are looking for fertilizer production equipment and production lines, feel free to contact us at any time.- Whatsapp(Tel): + 86 139-0548-5429( Mr. Li)

- E-mail: tahongxin@gmail.com