Description

A. Why Choose Organic Fertilizer? — From "Waste" to "Land Gold"

Are you struggling with these issues?

-

Environmental Pressure: Massive accumulation of livestock manure, causing foul odors and pollution.

-

Soil Degradation: Long-term chemical fertilizer use leading to soil compaction and declining crop quality/yield.

-

Budget Constraints: High costs of purchasing finished organic fertilizer and difficulty in controlling production budgets.

1. Definition of Organic Fertilizer

Organic fertilizer is a high-value nutrient source made from farm manure, livestock waste, crop straw, and food waste. Through scientific aerobic fermentation and precision processing, it serves as a premium alternative to chemical fertilizers, offering both nutrient supply and soil improvement.

2. Four Core Values for Guaranteed ROI

-

Soil Structure Improvement: Loosens soil and enhances water/nutrient retention, achieving sustainable soil fertility.

-

Premium Crop Quality: Increases sugar and vitamin content, helping products secure "Green" or "Organic" labels for higher market pricing.

-

Waste Valorization: Converts environmental liabilities into economic assets through green circular economy practices.

-

Significant Cost Advantage: Self-production reduces fertilizer costs by 30%-50% compared to purchasing, ideal for large-scale plantations and fertilizer enterprises.

B. Process Analysis: Turning "Waste" into "Gold"

Our production lines are optimized through 30+ years of practice, ensuring a transparent, efficient, and eco-friendly 5-step process.

-

Process Flow: Raw Material Pre-treatment → Efficient Fermentation/Composting → Crushing & Batching → Granulation → Drying & Cooling → Screening & Packaging.

-

Key Stages:

-

Step 1: Efficient Fermentation (The Core): Uses groove-type aerobic fermentation + dedicated windrow turners. Reaches 55-65°C in 7-15 days to eliminate pathogens and weed seeds while removing odors.

-

Step 2: Crushing & Batching: Crushes fermented material and adds N, P, K, or functional bacteria with a precision error of ≤2% to meet specific crop needs.

-

Step 3: Granulation (Value-Adding): We offer Disc Granulation (Small-mid scale), Drum Granulation (Mid-large scale), and Extrusion Granulation (High-fiber materials). Granulation rate ≥90%.

-

Step 4: Drying & Cooling: Reduces moisture to the 10%-15% safety line to prevent clumping while preserving nutrient integrity.

-

Step 5: Screening & Packaging: Finished granules are screened (oversize/undersize are recycled) and automatically weighed, bagged, and sealed.

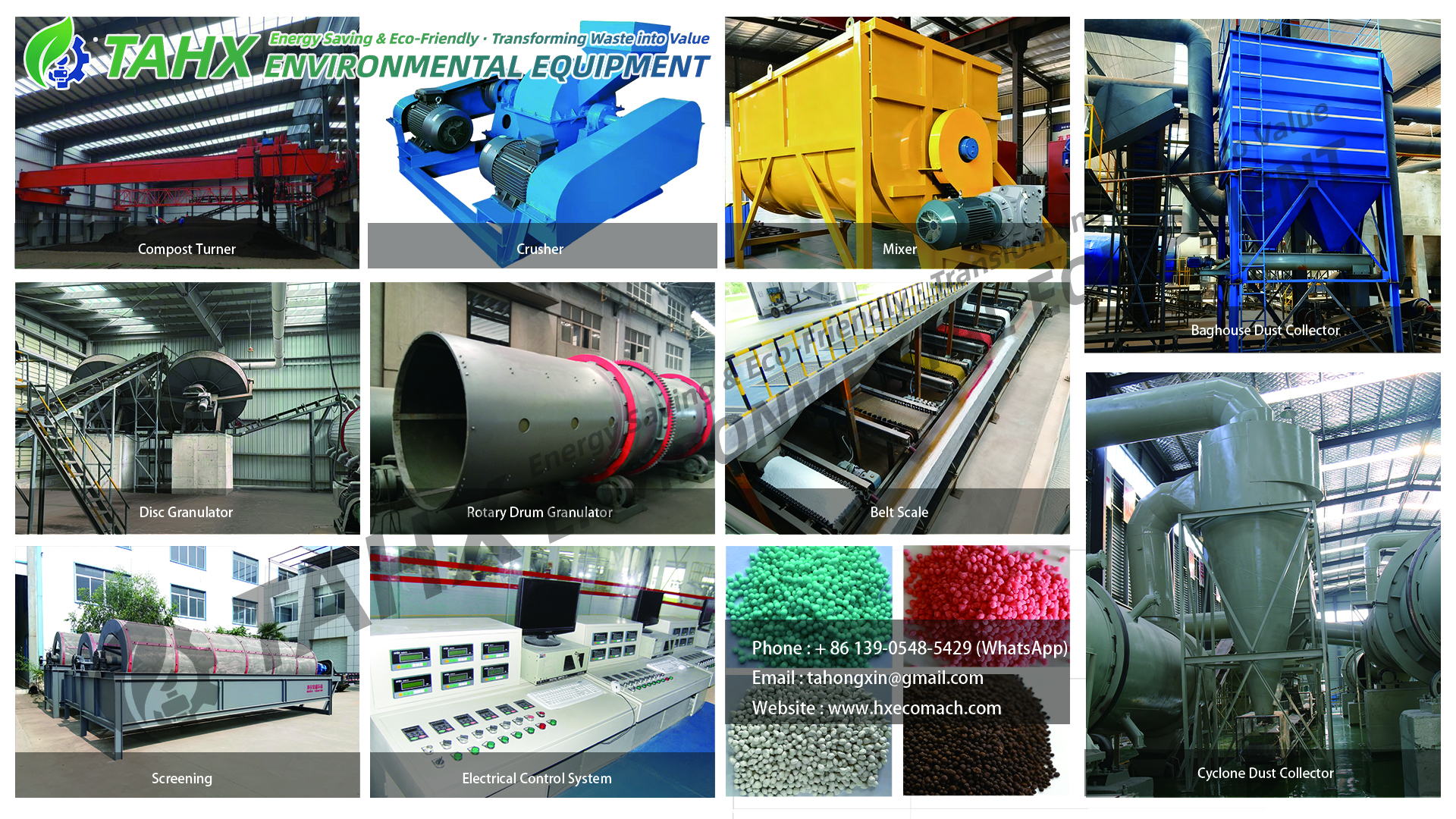

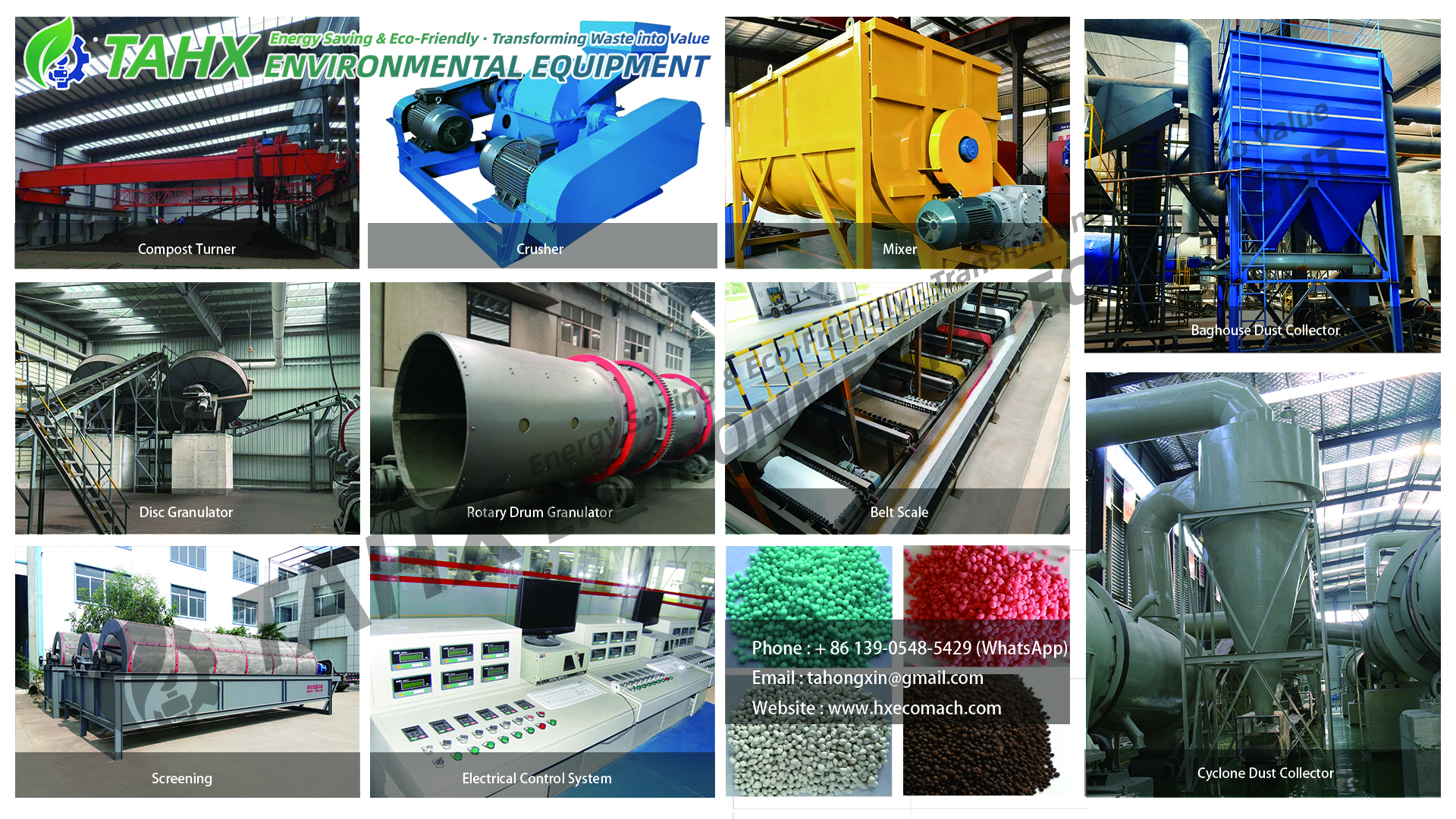

C. Reliable Production Tools: Our Equipment Advantages

We provide modular, high-durability equipment designed for stability and ease of use.

1. Modular Design

-

Flexible combinations based on material type and capacity (1t/h - 20t/h).

-

Modular upgrades allow for capacity expansion without replacing the entire system, lowering secondary investment costs.

2. High Durability & Low Failure Rate

-

Premium Materials: Crusher blades use 65Mn high-strength steel; Drum liners feature heat/acid-resistant rubber; Gears are made of cast steel, offering a lifespan 30% longer than industry averages.

-

Smart Automation: PLC control systems monitor fermentation temperature, granulation speed, and moisture levels automatically.

-

Maintenance-Friendly: Inspection ports and easy-access designs reduce maintenance time by 50%.

3. Production Line Configurations & Equipment List

| Production Line Type | Core Equipment List |

| Basic Powder Fertilizer Line | Groove Type Compost Turner, Double-Stage Crusher, Horizontal Mixer, Automatic Packaging Machine. |

| Granular Organic Fertilizer Line | Pre-treatment: Crusher + Mixer; Fermentation: Compost Turner / Fermentation Tank; Processing: Granulator, Rotary Dryer, Rotary Cooler, Vibrating Screen, Automatic Packaging Machine, Belt Conveyors. |

G. One-Stop Service & Compliance Assurance

Worry-Free Operation, Minimized Business Risks

We are more than just an equipment supplier; we are your "Technical Consultant & Risk Management Partner," providing end-to-end support from factory inception to daily operation.

1. Full Turnkey Solutions

-

Factory Layout Design: Based on your site area and capacity targets, we provide professional floor plans and equipment foundation drawings. We optimize logistics routes to maximize space efficiency and workflow.

-

Installation & Commissioning: Our dedicated engineering team provides on-site installation. Upon completion, we conduct a 72-hour trial run with live materials to ensure a stable production line (failure rate ≤1%) before final handover.

-

Personnel Training: We offer 3-5 days of systematic training (Theory + Hands-on) for your operators and maintenance staff, covering fermentation control, machine operation, and troubleshooting to ensure fully independent management.

-

Formula Support: We provide optimized fertilizer formulas customized for various raw materials, including chicken manure, cow dung, and food waste, ensuring high-quality output.

2. After-Sales Service Commitment

-

Rapid Response: We respond to equipment issues within 24 hours. Our engineers will arrive on-site within 48 hours (or 72 hours for remote regions).

-

Spare Parts Guarantee: High-wear components (such as hammer blades and bearings) are maintained in stock and shipped within 24 hours of order placement.

-

Regular Inspections: We conduct quarterly on-site check-ups to identify potential risks and provide professional maintenance advice, ensuring long-term, stable operation and maximum equipment lifespan.

Tai'an Hongxin Environmental:

Supply of High-Quality and Efficient Fertilizer Production Equipment, Straw Processing Equipment, Waste Treatment Equipment and Mining Equipment. If you are looking for fertilizer production equipment and production lines, feel free to contact us at any time.- Whatsapp(Tel): + 86 139-0548-5429( Mr. Li)

- E-mail: tahongxin@gmail.com