Description

A powder foliar and flush fertilizer production line is a series of automated equipment used to produce powdered fertilizers. Here is a detailed introduction to its components, workflow, and features.

I. Main Components

- Automatic Batching System: This system typically consists of raw material silos, feeding equipment, and batching scales. The silos store various raw materials. Feeding equipment like bucket elevators or screw conveyors transports the materials to the batching scales. The scales use high-precision weighing sensors and a PLC control system to achieve precise proportioning of multiple raw materials, with an error generally controlled to within ±0.1%-±0.2%.

- Mixing System: Common types include twin-screw mixers and vertical mixers. A twin-screw mixer uses the relative movement of inner and outer screws to create a complex convective motion of the materials inside the machine, achieving a uniform mix. The mixing uniformity can reach over 98%, which effectively prevents clumping and ensures stable fertilizer quality.

- Crushing System: If the raw material granules are too large or need further refinement, a crushing device is used, such as a hammer mill, a double-roller crusher, a self-cleaning crusher, or a horizontal chain mill. A hammer mill uses high-speed rotating hammer blades to impact and crush the material to the required fineness.

- Packaging System: This system generally includes an automatic quantitative packaging scale, a sealing machine, and a conveyor line. The automatic quantitative packaging scale precisely meters and fills the mixed powdered fertilizer to a set weight. The conveyor line then transports the bags to the sealing machine to complete the packaging process.

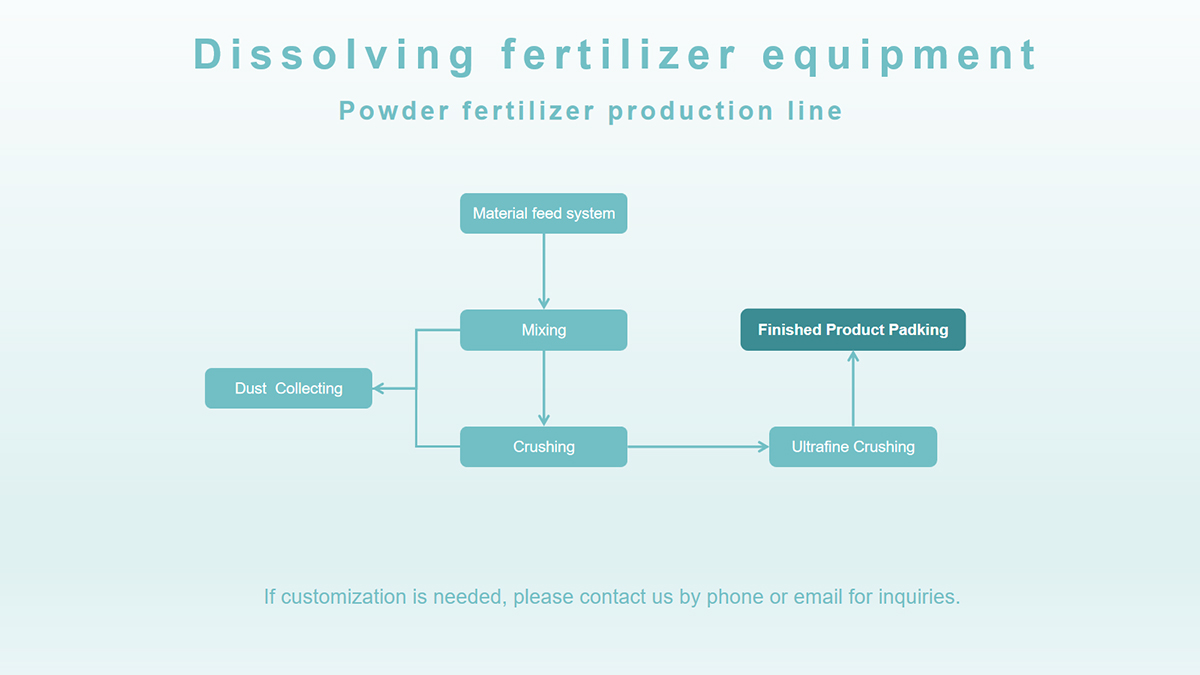

II. Workflow

- Raw Material Preparation: Workers manually load the various raw materials, such as NPK, micronutrients, etc., into low-level raw material bins according to a specific ratio and quantity.

- Batching: The raw materials are lifted by an automatic bucket elevator to a high-level batching storage bin. Then, feeding machines sequentially add the materials to a batching scale bucket according to the required amounts. After batching is complete, the discharge gate of the scale bucket opens for automatic unloading.

- Mixing: The batched materials enter the mixer for automatic, uniform mixing. The mixed materials are then conveyed by an elevator to a mixed material temporary storage bin, and then to a pending-packaging material bin.

- Packaging: The materials awaiting packaging enter the automatic quantitative packaging scale to be weighed to the set weight. At the same time, a worker places a bag on the spout. The worker then initiates the discharge command to fill the bag. After filling, the bag is conveyed by a belt conveyor to the automatic sewing machine station for assisted automatic sewing, completing the packaging.

III. Features of This Production Line

A powder foliar and flush fertilizer production line is a professional equipment combination for producing powdered water-soluble fertilizers. It has the following key features:

- High Degree of Automation Each stage of the production line uses automation. From raw material conveying, batching, and mixing to crushing and packaging, all processes are mechanized and automated. A PLC control system provides precise, full-process control, which reduces manual intervention and human error. This greatly improves production efficiency and stability while saving labor costs.

- Accurate and Controllable Batching It is equipped with high-precision metering devices, such as electronic belt scales and screw metering scales. These can precisely meter base raw materials like NPK, as well as additives like micronutrients and organic matter. It can accurately control the addition ratio of each raw material according to different fertilizer formula requirements, which ensures the nutrient content of the produced fertilizer meets design standards and guarantees uniform and stable fertilizer quality.

- High Mixing Uniformity and Controllable Fineness It uses high-efficiency mixing equipment, such as twin-shaft paddle mixers and vertical mixing mixers. These can thoroughly mix multiple raw materials in a short time with high uniformity, which avoids the problem of uneven nutrient distribution in the fertilizer. At the same time, the ultra-fine pulverizers and other equipment in the production line can crush the materials to a fineness that can be controlled as needed. This ensures the fertilizer dissolves quickly in water and improves fertilizer utilization.

- Flexible Production Adapts to Multiple Formulas The production line's design is highly flexible and adaptable. By adjusting the control system parameters, you can quickly switch between different production formulas to meet the market's demand for powder foliar and flush fertilizers with different nutrient ratios and functions. Whether it's a general-purpose fertilizer or a specialized one for a specific crop or soil type, it can achieve efficient production.

- Excellent Environmental and Safety Performance The production line is equipped with a complete dust collection and treatment system, such as a pulse dust collector. This effectively captures the dust generated during the production process, which reduces dust pollution, improves the workshop environment, and protects the health of the operators. The equipment also has safety features like overload protection and fault alarms to ensure a safe and reliable production process.

- Efficient Continuous Production with Adjustable Capacity The production line uses a continuous production model. The equipment is seamlessly connected, and materials can flow continuously between processes, which leads to high production efficiency. Additionally, the production line's capacity can be flexibly adjusted by changing the equipment's operating parameters or adding/removing equipment as needed, which adapts it to different production scales.

- Smart Control is Easy to Operate It uses a smart control system with a human-machine interface. Operators can intuitively monitor various parameters during the production process, such as material flow, mixing time, and temperature, and they can conveniently set and adjust parameters. The system also has data recording and traceability functions, which facilitates production management and quality tracking.

- Modular Design is Easy to Maintain The equipment in the production line generally uses a modular design, with a compact and reasonable structure that is easy to install and disassemble. This design not only facilitates the initial installation and debugging of the line but also allows for quick replacement and repair of components when a fault occurs, reducing downtime and maintenance costs. The modular design also provides convenience for future upgrades and modifications of the production line.

IV. Application Fields of the Powder Foliar and Flush Fertilizer Production Line

Powdered foliar and flush fertilizer is an efficient and convenient water-soluble fertilizer, and the application fields of its production line are highly compatible with the intensive and precise planting needs of modern agriculture. Relying on the standardized and large-scale production capabilities of the line, powdered foliar and flush fertilizer has been widely applied in multiple agricultural scenarios to provide precise nutritional support for the growth of various crops.

- In facility agriculture, the application of the powder foliar and flush fertilizer production line is particularly widespread. Environments like greenhouses and smart greenhouses are highly intensive, with short crop growth cycles and a large but precise need for fertilizer. Powdered foliar and flush fertilizer can be directly absorbed by the crop's roots through fertigation systems like drip irrigation and sprinkler irrigation, which reduces fertilizer loss and improves utilization. The production line can flexibly adjust the ratio of NPK and micronutrients according to the growth stage and nutritional needs of different facility crops (e.g., tomatoes, cucumbers, and peppers) to produce customized fertilizers that meet the "fast and efficient" planting needs of facility agriculture.

- In large-scale field crop cultivation, the powder foliar and flush fertilizer production line also plays an important role. Bulk field crops like corn, wheat, and rice have a high demand for nutrients during their rapid growth period, and traditional top-dressing methods have problems like high labor intensity and low fertilizer utilization. Powdered foliar and flush fertilizer can be uniformly applied over large areas through large-scale irrigation equipment, and the production line's large-scale production capability can guarantee the large demand for fertilizer for field crops. The production line can also produce highly adaptable fertilizer products for different regional soil fertility characteristics and crop varieties, which helps field crops improve quality and increase yield.

- Fruit tree cultivation is one of the key application scenarios for the powder foliar and flush fertilizer production line. Fruit trees like apples, oranges, grapes, and pears have long growth cycles and their nutritional needs are phased and diverse. For example, they need phosphorus to promote flowering during the blooming period and potassium to increase sweetness during the fruit expansion period. The production line can produce high-phosphorus, high-potassium, and balanced fertilizers according to the nutritional needs of fruit trees at different growth stages. When applied through fertigation technology, the fertilizer can quickly permeate the soil around the fruit tree roots, promoting fruit expansion and improving fruit quality. The production line can also add functional substances like humic acid and amino acids to enhance the fruit trees' resistance to stress and reduce the occurrence of pests and diseases.

- Vegetable cultivation, whether in open fields or protected cultivation, benefits from the support of the powder foliar and flush fertilizer production line. Leafy vegetables (e.g., lettuce, spinach) need nitrogen to promote leaf growth, root vegetables (e.g., radishes, potatoes) need potassium to promote tuber development, and fruiting vegetables (e.g., eggplants, green beans) need balanced nutrition to ensure yield. The production line can precisely control the fertilizer's nutrient ratio to produce highly targeted special fertilizers for vegetables. The powdered fertilizer dissolves quickly without residue and will not clog irrigation pipes, which is suitable for the high-frequency, small-dose top-dressing needs in vegetable cultivation, helping to achieve high yield and quality.

- In economic crop cultivation, the application value of the powder foliar and flush fertilizer production line is significant. Economic crops like strawberries, blueberries, tea, and tobacco have very high quality requirements, and their economic benefits are closely related to their fruit flavor and nutrient content. The production line can produce special fertilizers rich in micronutrients and functional components. Through precise fertilization, it can improve the quality of economic crops. For example, applying a high-potassium powdered foliar and flush fertilizer during the strawberry fruit expansion period can increase the fruit's sweetness and luster. Applying a fertilizer containing magnesium and zinc during tea growth can increase the tea polyphenol content. The line's customized production capability meets the "quality first" planting goal of economic crops.

- The floriculture and horticulture field also benefits from the development of the powder foliar and flush fertilizer production line. Cut flowers and potted flowers have strict requirements for fertilizer purity and safety. Traditional fertilizers can cause root burn and stain petals. The powder foliar and flush fertilizer production line uses high-purity raw materials. The fertilizer dissolves without residue and can be applied via foliar spraying or root irrigation to meet the nutritional needs of flowers at different growth stages. The production line can also produce special fertilizer formulas, such as low-nitrogen and high-phosphorus or high-calcium and high-magnesium, based on the characteristics of different flower varieties (e.g., roses, lilies, succulents) to promote flowering, extend the flowering period, and enhance ornamental value.

- In large-scale planting bases and modern agricultural industrial parks, the powder foliar and flush fertilizer production line is one of the key pieces of equipment for standardized planting. These bases cultivate a wide variety of crops over large areas and have high demands for fertilizer consistency and stability. The production line uses automated control to ensure the fertilizer formula is precise, the mixing is uniform, and the quality is stable, which guarantees the uniformity of the nutrient supply in large-scale planting. The line's continuous production capability also lowers fertilizer production costs, improves the economic benefits of the planting base, and promotes the development of agricultural production toward modernization and industrialization.

V. Key Selection Criteria for a Powder Foliar and Flush Fertilizer Production Line

When selecting a powder foliar and flush fertilizer production line, you need to consider multiple factors comprehensively to ensure that the line can meet production needs, operate efficiently and stably, and be economically and environmentally friendly. Here are the key selection criteria:

- Define the Production Scale The production scale is the basis for selecting the production line. You need to determine the line's specifications based on your company's output needs.

- (1) Small-scale Production Line: Suitable for startups or situations with low output needs, typically with an annual output of 500-2,000 tons. The equipment configuration is relatively simple, and you can choose a small mixer, crusher, and semi-automatic packaging machine. It has a smaller footprint and lower initial investment cost.

- (2) Medium-scale Production Line: Annual output is generally 2,000-10,000 tons, suitable for companies with a certain market share. It needs to be configured with more efficient mixing equipment, a continuous crushing device, and a highly automated metering and packaging system. It can achieve batch production and improve production efficiency.

- (3) Large-scale Production Line: For large companies with an annual output of over 10,000 tons, the production line must have a high degree of automation and continuous production capability. It needs to be equipped with a large mixing unit, an intelligent raw material conveying system, online detection equipment, and a fully automatic packaging and palletizing line to achieve large-scale, high-efficiency production.

- Consider Raw Material Characteristics The physical properties of the raw materials for powdered foliar and flush fertilizer vary greatly, which directly affects the equipment selection.

- (1) Hygroscopicity: For highly hygroscopic raw materials (e.g., urea, potassium nitrate), you need to choose mixing equipment with anti-sticking functions, such as a mixer with a heated insulation layer. The conveying pipes should also use anti-sticking materials to prevent the raw materials from clumping and clogging.

- (2) Flowability: Raw materials with poor flowability (e.g., some micronutrient fertilizers) require special conveying devices. You can choose a screw conveyor equipped with a vibration device or a pneumatic conveying system to ensure a smooth material flow.

- (3) Particle Size and Hardness: If the raw material particle size is uneven or contains hard particles, you need to configure a suitable crushing device at the front end of the production line. For harder materials, you should choose a hammer mill or an impact crusher with strong crushing capabilities to ensure the raw material particle size meets production requirements.

- (4) Corrosiveness: If the raw materials are corrosive (e.g., monoammonium phosphate, potassium sulfate), the equipment parts that contact the materials must be made of corrosion-resistant materials, such as stainless steel, to extend the equipment's service life.

- Evaluate the Level of Automation The level of automation affects production efficiency, product quality stability, and labor costs. You need to balance these when making a choice based on your company's situation.

- (1) Basic Automation: This includes automatic feeding, automatic mixing, and a semi-automatic packaging system. It can reduce manual intervention and labor intensity and is suitable for small and medium-sized companies. For example, sensors can control the amount of raw material added, and the mixer can automatically time the mixing.

- (2) High Automation: This uses a PLC control system to achieve full-process automated control of raw material conveying, mixing, crushing, metering, and packaging. Parameters can be set via a human-machine interface, and the production process can be monitored in real time, with production data automatically recorded. This facilitates quality tracking and production management and is suitable for large companies or situations with high precision requirements.

- (3) Smart Upgrades: Some high-end production lines can introduce IoT technology to achieve remote monitoring and fault diagnosis. Through data analysis, they can optimize the production process and improve production efficiency and product quality stability, but the initial investment cost is higher.

- Pay Attention to Equipment Compatibility The production line must have a certain degree of flexibility to adapt to the production needs of different formulas.

- (1) Formula Adjustment Adaptability: The mixing equipment should be able to adapt to the mixing requirements of different raw material ratios and have good mixing uniformity. The metering system should be able to flexibly adjust the amount of each raw material added to meet the production needs of different formulas.

- (2) Equipment Versatility: Try to choose equipment with high versatility to reduce the cost of replacing equipment when adjusting product types. For example, the screen of the crusher can be replaced to adapt to the crushing of raw materials with different particle size requirements.

- Focus on Energy Consumption and Environmental Friendliness In the context of increasingly strict environmental requirements, energy consumption and environmental indicators are important considerations for production line selection.

- (1) Energy Consumption Indicators: Compare the energy consumption parameters of different pieces of equipment and choose energy-saving ones. For example, choose mixers and crushers with high-efficiency motors to reduce the energy consumption per unit of product. Also, optimize the production process to reduce the equipment's no-load operation time.

- (2) Environmental Facilities: The production line must be equipped with a complete set of environmental equipment, such as a dust collection system. Dust collectors should be installed at the raw material conveying, crushing, and packaging stages to prevent dust pollution. If the production process generates waste gas, a waste gas treatment system needs to be installed to ensure compliance with emission standards. Additionally, the equipment noise should comply with national standards, and sound insulation measures should be taken if necessary.

- Evaluate Equipment Quality and After-Sales Service Equipment quality is directly related to the stable operation of the production line, and after-sales service ensures the long-term maintenance of the equipment.

- (1) Equipment Material: The material of the core equipment must meet the production requirements. For example, the agitator blades of the mixer and the hammer heads of the crusher should be made of high-strength, wear-resistant materials to extend the service life of wear parts. The equipment's welding and sealing processes should be excellent to ensure safe and reliable operation.

- (2) Manufacturer Reputation and Qualifications: Choose an equipment manufacturer with a good reputation and rich experience. Check whether they have relevant production qualifications and certifications. Understand the manufacturer's technical strength, production scale, and past customer cases to evaluate their equipment quality and credibility.

- (3) After-Sales Service: Be clear about the content of the manufacturer's after-sales service, including equipment installation and debugging, operator training, and equipment maintenance. Ensure the manufacturer can provide timely after-sales support, such as a quick response to equipment failures and repair services, to reduce production downtime.

- Pay Attention to Metering and Packaging Accuracy Metering and packaging accuracy directly affect product quality and market reputation.

- (1) Metering System: Choose high-precision metering equipment, such as electronic belt scales and loss-in-weight feeders, to ensure the accuracy of the raw material addition and that the product's nutrient content meets standards. The metering system should have good stability and anti-interference capability to reduce metering errors.

- (2) Packaging Equipment: Choose the appropriate packaging machine based on the product packaging specifications, such as a granule packaging machine or a powder packaging machine. The packaging machine should have a high packaging speed and precision to ensure the package weight meets requirements. Additionally, the packaging machine's sealing performance should be good to prevent the product from absorbing moisture and clumping, which ensures the product's quality stability during storage and transportation.

- Consider Site and Cost Factors

- (1) Site Layout: Reasonably plan the factory layout based on the size of the production line equipment and the production process. Ensure there is enough operational space and passages between the equipment for easy operation, maintenance, and material transportation. Also, consider the storage areas for raw materials and finished products, as well as the layout of utilities like water, electricity, and ventilation.

- (2) Cost Budget: While meeting production needs, comprehensively consider the costs of equipment purchase, installation, and operation (e.g., energy, labor, maintenance). Conduct a cost accounting and ROI analysis to choose a cost-effective production line solution, avoiding over-investment or production issues due to a simplified setup.

- Reference Industry Cases and Market Feedback When selecting a production line, you can refer to the production line configurations and operational status of other companies in the same industry to understand the actual usage effects of different pieces of equipment. By attending industry exhibitions and communicating with peers, you can collect market feedback to understand the pros, cons, and application scope of various pieces of equipment. This provides a good reference for selection and reduces the risk of making a wrong choice.

In short, selecting a powder foliar and flush fertilizer production line is a comprehensive decision that requires considering production scale, raw material characteristics, automation level, equipment compatibility, energy consumption and environmental friendliness, equipment quality and after-sales service, metering and packaging accuracy, site and cost factors, and industry cases. You should choose the most suitable production line solution based on your company's situation to achieve an efficient, stable, economic, and environmentally friendly production goal.

Tai'an Hongxin Environmental:

Supply of High-Quality and Efficient Fertilizer Production Equipment, Straw Processing Equipment, Waste Treatment Equipment and Mining Equipment. If you are looking for fertilizer production equipment and production lines, feel free to contact us at any time.- Whatsapp(Tel): + 86 139-0548-5429( Mr. Li)

- E-mail: tahongxin@gmail.com