Description

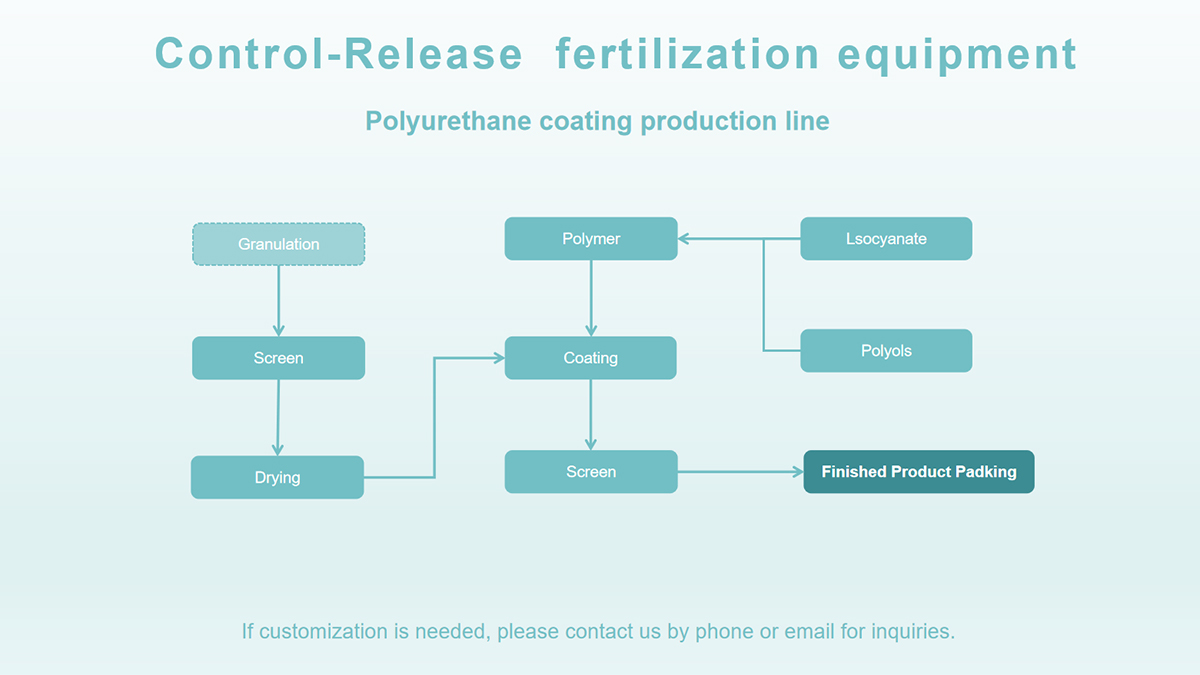

In modern agriculture, the efficient use of fertilizer is critical. Polyurethane-coated fertilizer, an advanced type of slow- and controlled-release fertilizer, can effectively improve fertilizer utilization, reduce nutrient loss, and lower the frequency of fertilization, making it highly significant for sustainable agricultural development. The fertilizer granule polyurethane coating production line is the key equipment for producing these high-quality fertilizers.

I. Production Line Composition

- Raw Material Pre-treatment System

- Screening Device: This system screens the uncoated fertilizer granules to remove oversized or undersized particles and impurities. It ensures that the granules entering the coating stage have a uniform particle size. Commonly used equipment includes vibrating screens and drum screeners, which can achieve high screening precision to accurately select granules that meet production requirements.

- Preheating and Polishing Equipment: This device heats and polishes the fertilizer granules to make their surfaces smooth, removing micro-corners and salt crystals that may have precipitated during the cooling process. The granules are typically heated to 50-70°C (122-158°F). This temperature smooths the surface without affecting the fertilizer's chemical properties, which is crucial for the integrity and uniformity of the subsequent coating. A rotary drum preheater and polisher can be used for continuous production.

- Coating System

- Drum Coater: This is the core equipment for coating. The pre-treated fertilizer granules are fed into the drum, where they tumble continuously as the drum rotates. At the same time, the polyurethane coating materials are added in batches from a specific inlet. For example, the addition of each batch of coating material is controlled to be 0.5-1wt% of the fertilizer's weight. This is repeated until the total amount of polyurethane coating material reaches 3-5wt% of the fertilizer's weight. The rotation speed and tilt angle of the drum can be adjusted based on production needs to ensure coating uniformity.

- Polyurethane Coating Material Supply Device: This device heats and precisely meters the polyurethane coating materials—typically including Component A (polyether polyol, epoxidized soybean oil polyol, castor oil, chain extenders, etc.) and Component B (isocyanate)—before conveying them to the drum coater. A precise flow control device ensures the stable and accurate addition of the coating materials, allowing them to fully contact the fertilizer granules and react to form the coating.

- Post-treatment System

- Cooling Device: The coated fertilizer granules have a high temperature and need to be cooled down to room temperature for subsequent packaging and storage. This is usually done with air or water cooling, for example, by a forced-air cooling tunnel that blows air over the granules to quickly remove heat.

- Screening Device (Second Screening): The cooled fertilizer granules are screened again to remove any clumps or off-spec products that may have formed during the coating process. This device is similar to the pre-treatment screener but with more stringent standards to ensure only high-quality coated fertilizer granules proceed to the packaging stage.

- Packaging Equipment: The final, qualified coated fertilizer granules are packaged by weight. An automatic packaging machine is typically used for fast and accurate metering and packaging, which improves production efficiency. The packaging materials are usually moisture-proof and pressure-resistant woven or plastic bags to maintain the fertilizer's quality during storage and transportation.

II. Working Principle

- First, the fertilizer granules are screened and preheated/polished in the raw material pre-treatment system. Screening removes off-spec granules and impurities, and preheating/polishing smooths the surface, which minimizes negative effects on the integrity of the subsequent coating.

- In the coating system, the drum coater tumbles the fertilizer granules continuously. Components A and B of the polyurethane coating material are heated and added to the drum in specific proportions and batches. The polyether polyol, epoxidized soybean oil polyol, castor oil, and other ingredients in Component A react chemically with the isocyanate in Component B on the surface of the fertilizer granules to form the polyurethane coating. The epoxidized soybean oil polyol has a high hydroxyl value and low acid value, which increases the reaction speed with isocyanate, promoting the curing of the coating and reducing clumping. The addition of polyether polyol gives the polyurethane molecule chains multiple functional groups, which enhances the coating's strength and toughness. By controlling the amount of material added in each batch and the reaction time, the coating is gradually formed and fully cured on the surface of the fertilizer granules, ensuring its integrity and uniformity.

- The completed coated fertilizer granules enter the post-treatment system, where they are first cooled, then undergo a second screening to remove off-spec products, and are finally packaged for market sale.

III. Features of the Fertilizer Granule Polyurethane Coating Production Line

The fertilizer granule polyurethane coating production line is a key piece of equipment for producing slow-release fertilizers. It integrates technologies from materials science, automated control, and fine chemistry. Its core features are as follows:

- Precision Process, Ensures Coating Quality The production line uses a multi-stage pre-treatment system with vibrating screening and airflow classification technology. This ensures that the granules entering the coating stage have a particle size deviation of less than ±0.5mm and a surface moisture content of less than 1%, which is the foundation for a uniform coating. The coating stage uses a fluidized bed-drum composite coating technology. A high-pressure atomizing nozzle (with an atomized particle size of 5-10μm) sprays the polyurethane emulsion uniformly, and this is combined with precise hot air circulation (with a temperature fluctuation of ≤±2°C) and regulated material tumbling speed. This allows for the coating thickness deviation to be controlled to within 5%, effectively avoiding common issues in traditional processes, such as bare spots and clumping.

- Smart Automation, Boosts Production Efficiency The entire line is equipped with a PLC control system and a sensor network that monitors over 20 key parameters in real time, including temperature, humidity, material flow, and emulsion concentration. It uses a PID algorithm to automatically adjust the operating status of each stage, enabling a fully automated process from raw material input to finished product packaging. The central control system has a production data traceability platform that can record process parameters and quality test results for each batch, supporting production process visualization and historical data review. A single production line can achieve a daily capacity of 80-120 tons, which is over 40% more efficient than traditional manual lines.

- Eco-Friendly and Energy-Saving Design, Aligns with Green Production To control the volatiles produced during the polyurethane coating process, the line uses a closed-loop waste gas collection-adsorption treatment system. Through activated carbon adsorption + catalytic combustion, the concentration of organic waste gas emissions is below 30mg/m³, which is far below national standards. The drying and curing stages use heat pump waste heat recovery technology, which raises the thermal efficiency to over 75% and reduces energy consumption per unit of product by 30% compared to traditional hot air drying. The line also has a wastewater recycling system, where cleaning wastewater is settled and filtered for reuse, achieving a water recycling rate of 90%.

- Strong Product Adaptability, Meets Diverse Needs The production line has a modular design. By changing different specifications of atomizing nozzles and adjusting the bed height and hot air parameters, it can flexibly produce a series of products with coating thicknesses from 0.05-0.3mm, and it is compatible with different base fertilizer types, such as NPK. To meet the needs of different crop growth stages, the line can adjust the polyurethane emulsion formula and coating process parameters to precisely control the fertilizer's slow-release period from 2 months to 12 months, which satisfies the needs of large-scale field crops, economic crops, and horticultural flowers.

- High Quality Stability, Lowers Production Costs The online quality detection system integrates a near-infrared spectrometer and a laser thickness gauge to provide real-time detection of coating uniformity and nutrient content. It removes off-spec products, keeping the finished product pass rate stable at over 99%. The key components are made of wear-resistant stainless steel and ceramic materials, and the coating drum's service life can reach over 10,000 hours, which reduces equipment maintenance frequency. By precisely controlling the amount of polyurethane emulsion used (with an error of ≤2%), it reduces raw material waste, and the comprehensive production cost is 15-20% lower than that of traditional processes.

- Safe and Reliable Operation, Ensures Production Continuity The production line has multiple safety protection mechanisms, including overload protection, high-temperature alarms, and emergency shutdown interlocks. Key equipment is equipped with a redundant power system, so the line can operate in a degraded mode if a single point of failure occurs. The equipment's operating noise is controlled to below 85dB, and a fully enclosed design reduces dust overflow. The dust concentration in the work environment is below 10mg/m³, which complies with occupational health and safety standards and provides a guarantee for long-term stable production.

IV. Application Scenarios

- Field Crops: Widely used in the cultivation of field crops such as corn, wheat, and rice. Taking corn cultivation as an example, polyurethane-coated urea can be applied as a base fertilizer in a single application. Its nutrient release pattern matches the corn's growth cycle. It slowly releases nutrients in the early growth stage to meet the needs of the seedlings. As the corn grows and the ground temperature rises, nutrient release accelerates, providing sufficient nutrition for the mid-to-late growth stages, which reduces the number of top-dressing applications and improves planting efficiency. For spring corn, using 40-50 pounds of controlled-release urea per acre, with an appropriate amount of monoammonium phosphate or diammonium phosphate and potassium fertilizer, yields good results. For summer corn in regions south of Beijing and Tianjin, using 50 pounds of controlled-release urea per acre can achieve good results because the residual potassium and phosphorus in the soil from the spring planting are generally sufficient to meet its growth needs.

- Economic Crops: Polyurethane-coated fertilizers also have significant advantages in the cultivation of high-value economic crops like vegetables, fruit trees, and flowers. For vegetables, the fertilizer can precisely control nutrient release based on the growth characteristics and nutrient requirements of different vegetable varieties, which improves vegetable yield and quality and reduces the occurrence of pests and diseases. In fruit tree cultivation, it can ensure a continuous and stable supply of nutrients throughout the tree's growth cycle, promoting fruit expansion and improving fruit sugar content and color. For flowers, it can make them grow more robustly, have more vibrant colors, and extend their flowering period. For example, Wisen Union's fertilizer products are suitable for drip irrigation, fertigation, and foliar spraying and are primarily targeted at the high-value economic crop market for fruit trees, vegetables, and flowers. Their bio-based polyurethane-coated controlled-release fertilizer effectively helps increase crop yields.

- Regions with Different Soil Conditions: Polyurethane-coated fertilizer works well in both arid regions and areas with high rainfall. In arid regions, the coating can prevent slow nutrient release caused by insufficient moisture. When a small amount of water enters the coating, the fertilizer begins to slowly release nutrients, which improves its effectiveness under dry conditions. In high-rainfall areas, the coating can effectively block rainwater runoff, preventing the rapid loss of fertilizer nutrients and maintaining a stable nutrient supply in the soil.

The fertilizer granule polyurethane coating production line, with its scientifically designed system and advanced working principles, produces polyurethane-coated fertilizer with numerous advantages and has broad application prospects in various fields of agricultural production. As technology continues to advance and improve, this production line will play an even more important role in improving fertilizer utilization and promoting sustainable agricultural development, bringing higher economic and environmental benefits to agriculture.

V. Key Selection Criteria for a Fertilizer Granule Polyurethane Coating Production Line

In the fertilizer production industry, choosing the right fertilizer granule polyurethane coating production line is crucial for a company's production efficiency, product quality, and cost control. Here are the key selection criteria, broken down by several important aspects:

- Production Needs Matching Matching production needs is the foundation for choosing a production line. You need to fully consider your company's actual production situation.

- Capacity Needs: Different-sized companies have very different capacity requirements. A small company might only need to meet small-batch production, while a large company requires a high-capacity production line. The line's designed capacity must match your company's actual needs to avoid wasted resources from excessive capacity or an inability to meet market demand from insufficient capacity.

- Fertilizer Granule Characteristics: The size, hardness, density, and other characteristics of the fertilizer granules directly affect the coating results and equipment requirements. For example, smaller granules may need a more precise nozzle and a gentler mixing method to prevent granule breakage, while granules with lower hardness require controlled mixing intensity to avoid fragmentation.

- Product Specifications: The required coating thickness and slow-release period are important indicators of product specifications. Different coating thicknesses and slow-release periods require different process parameters and equipment configurations. If you need a thicker coating layer or a longer slow-release period, you might need a multi-stage coating process and more precise drying temperature control. The production line must have the corresponding adjustment capabilities.

- Core Equipment Performance The performance of the core equipment directly determines the operating effect of the coating production line and the quality of the final product.

- Coater: As the key equipment, its structural design is crucial. Common types are drum coaters and fluidized bed coaters. A drum coater's drum tilt angle and rotation speed must have a flexible adjustment range to ensure the granules tumble uniformly, avoiding clumping or granule abrasion. A fluidized bed coater, on the other hand, needs to ensure uniform airflow distribution so that the granules can be fully suspended and contact the coating liquid.

- Atomization System: The atomization effect of the polyurethane coating liquid directly affects coating uniformity. The nozzle's material must have good corrosion resistance to withstand the characteristics of the polyurethane coating liquid. The atomization pressure adjustment accuracy must be high so that it can be precisely adjusted for different coating needs. The nozzle should also be easy to clean and maintain to reduce downtime.

- Drying System: The drying efficiency and temperature control after coating are extremely critical. If the temperature is too high, it may damage the performance of the polyurethane film and affect the fertilizer's slow-release effect. If the temperature is too low, it will lead to incomplete drying and cause granule clumping. Therefore, the drying equipment must have high thermal efficiency, good temperature uniformity, and flexible airflow adjustment capabilities.

- Process Adaptability The production line must have good process adaptability to meet different production needs and process requirements.

- Formula Adjustment Flexibility: The viscosity, solid content, and other parameters of the polyurethane coating liquid can vary depending on the formula. The production line should be able to adapt to different formula adjustments. For example, the liquid supply speed and atomization parameters should be flexibly adjustable to ensure a good coating effect with different formulas.

- Level of Automation: A higher level of automation can reduce manual intervention and improve production stability. The production line should be equipped with an advanced PLC control system for precise parameter control and online monitoring, such as real-time detection and adjustment of granule temperature, moisture, coating thickness, and other parameters.

- Continuous Production Capability: A production line that supports continuous feeding, coating, and drying can reduce batch-to-batch differences and improve production efficiency. A line with strong continuous production capability can achieve a stable production process and lower production costs.

- Environmental and Safety With increasingly strict environmental requirements, the environmental and safety performance of the production line cannot be overlooked.

- Waste Gas Treatment System: Organic solvents may be used during the polyurethane coating process, and the resulting waste gas needs to be effectively collected and treated. The production line should be equipped with a comprehensive waste gas treatment system, such as activated carbon adsorption or catalytic combustion, to ensure that waste gas emissions comply with environmental standards.

- Sealing Performance: Good sealing performance of the equipment can prevent solvent leakage and dust from escaping, which protects the health of operators and reduces environmental pollution.

- Safety Protection Devices: The production line should be equipped with necessary safety protection devices, such as overload protection and emergency shutdown devices. For production stages involving flammable and explosive solvents, it must also have an explosion-proof design to ensure production safety.

- Cost-Effectiveness When choosing a production line, you need to conduct a comprehensive cost-effectiveness analysis.

- Initial Investment Cost: The price of production lines from different brands and with different configurations varies greatly. A company should combine its own capacity needs and performance requirements to comprehensively evaluate the initial investment cost, avoiding blindly pursuing a low price and neglecting equipment quality and performance.

- Operating Costs: Operating costs include energy (electricity, heat), consumables (nozzles, filter elements), and labor costs. A highly automated production line can reduce labor costs, while equipment with low energy consumption and long-lasting consumables can lower long-term operating costs.

- Equipment Durability: The material and service life of core components directly affect the equipment's durability. Choosing equipment made of high-quality corrosion-resistant materials like stainless steel can reduce the frequency of maintenance and replacement, which lowers long-term costs.

- After-Sales Service and Technical Support Good after-sales service and technical support are a guarantee for the long-term stable operation of the production line.

- Technical Strength: The supplier should have strong technical capabilities and be able to provide professional process debugging guidance. Since the polyurethane coating process is complex, the supplier's technical support is crucial for optimizing process parameters and improving product quality.

- After-Sales Service Response Time: A company needs to consider whether the supplier can provide timely repair services when a machine breaks down to reduce downtime losses.

- Training Services: The supplier should provide comprehensive training services, including training for operators and equipment maintenance training, to ensure that company employees can skillfully operate and maintain the equipment and ensure the normal operation of the production line.

- Industry Standards and Market Reputation

- Compliance with Industry Standards: The production line must comply with relevant industry standards and regulations for fertilizer production to ensure the quality of the coated product meets requirements. A company should verify whether the production line has passed relevant certifications and tests.

- Market Reputation: A supplier's past cases and customer reviews can, to some extent, reflect the reliability of their production line. Choosing a supplier with a good market reputation and high customer reviews can reduce investment risk.

In summary, when choosing a fertilizer granule polyurethane coating production line, a company needs to comprehensively consider production needs, core equipment performance, process adaptability, environmental and safety, cost-effectiveness, after-sales service and technical support, and industry standards and market reputation. This will allow them to choose the production line that is most suitable for their development.

Tai'an Hongxin Environmental:

Supply of High-Quality and Efficient Fertilizer Production Equipment, Straw Processing Equipment, Waste Treatment Equipment and Mining Equipment. If you are looking for fertilizer production equipment and production lines, feel free to contact us at any time.- Whatsapp(Tel): + 86 139-0548-5429( Mr. Li)

- E-mail: tahongxin@gmail.com