Description

An organic fertilizer rotary drum granulation production line is a system for turning organic materials into granular fertilizer. Here is a detailed introduction to its working principles, equipment composition, production process, and its advantages and disadvantages.

I. Working Principle

- Rotational Movement: The main body of the rotary drum granulator is a tilted, rotating cylinder. Driven by a motor and a speed reducer, the cylinder rotates at a certain speed. This rotation causes the materials fed into the drum to roll and tumble under the combined forces of centrifugal force, gravity, and friction.

- Agglomeration Granulation: Under wet conditions, powdered organic materials are sprayed with water or a binder (like molasses or clay) to reach an optimal moisture level for granulation, typically 30%-50%. In this state, the powdered materials gradually stick together to form small particles. These particles then grow and become more compact through rolling and colliding with each other.

- Drying and Solidification: The rotary drum granulator is often equipped with a hot air system that dries the granules during the granulation process. This evaporates moisture and strengthens the granules, helping them to solidify and form.

II. Equipment Composition

- Rotary Drum Granulator: This is the core equipment. It is installed at an adjustable angle, usually between 2° and 10°. The inside is lined with wear- and acid/alkali-resistant rubber plates or has baffles to enhance the tumbling effect and promote granule formation.

- Transmission System: Consisting of a motor and a speed reducer, this system drives the rotation of the drum, providing power for the granulation process. The drum's rotation speed can be controlled by adjusting the motor speed and the transmission ratio of the speed reducer.

- Spraying Device: Installed inside or above the drum, this device uniformly sprays liquid binder or water onto the material. It helps to adjust the material's moisture level, which promotes the formation and growth of granules.

- Hot Air System: Mainly used for drying the granules, this system consists of a hot air furnace, a fan, and pipelines. Hot air can be blown into the drum as needed to accelerate moisture evaporation and improve the granules' drying speed and strength.

- Support Wheel System: This system supports the drum cylinder and allows for adjustment of the drum's tilt angle. This controls the material's retention time inside the drum, which in turn affects the size and quality of the granules.

- Feeding System: This includes a feed hopper and conveyors to uniformly feed the pre-treated organic raw materials and auxiliary materials into the drum.

- Discharging System: Located at the end of the drum, this system discharges the granulated fertilizer.

- Screening System: This system sifts the granulated particles, separating those that do not meet the standard size. It typically includes a screen, a vibrating or transmission device, a hitting device, and a hopper.

- Crusher System: This system takes the off-spec granules and re-crushes them into powder, allowing them to be re-granulated. This improves raw material utilization and product quality.

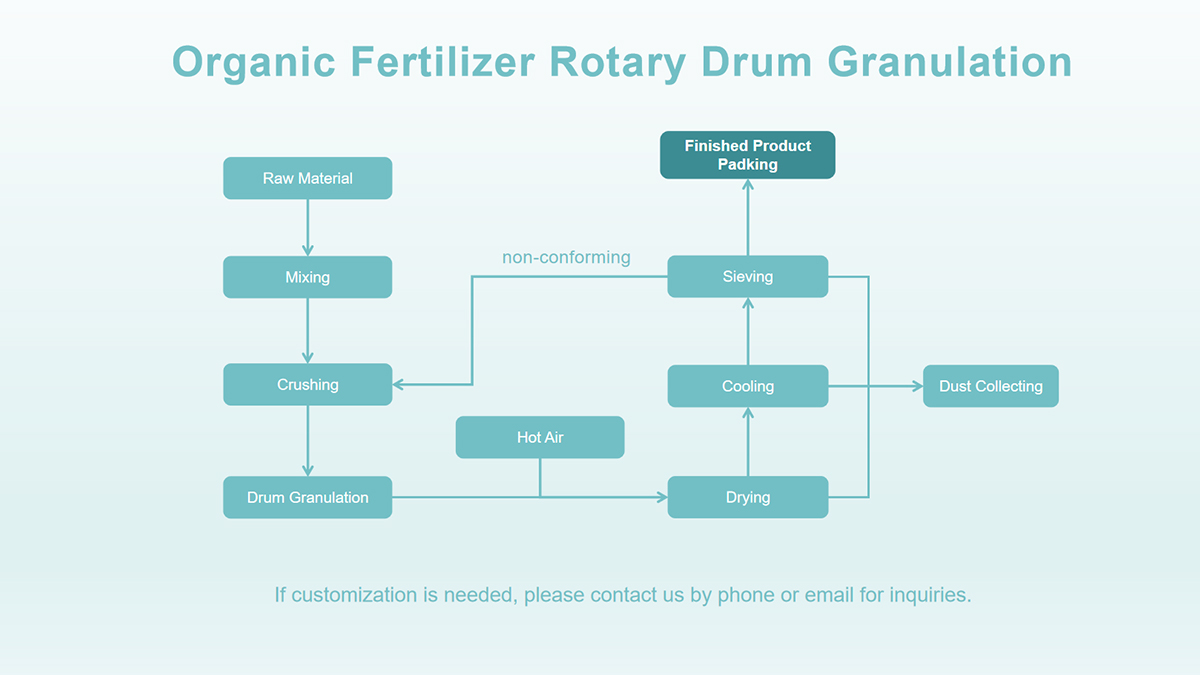

III. Production Process

- Raw Material Pre-treatment: Required organic raw materials, such as fermented animal manure or straw powder, along with auxiliary materials like humic acid and microbial agents, are pre-treated by crushing and mixing to ensure uniform particle size and composition.

- Raw Material Moistening: An appropriate amount of water or binder is added to the pre-treated materials via a spraying system, bringing the moisture content to an optimal level for granulation, typically between 30% and 50%.

- Rotary Drum Granulation: The moistened materials are fed into the rotary drum granulator. As the drum rotates at a low speed, the materials continuously tumble, rub, and compress inside the cylinder, gradually forming granules.

- Granule Drying: The wet granules are sent through drying equipment, such as a dryer, to reduce their moisture content to a specified level.

- Granule Cooling: The dried granules are cooled, for example, by using air cooling, to lower their temperature and further increase their hardness and stability.

- Granule Screening: A screening device, such as a vibratory or trommel screen, separates the granules that do not meet the standard size. The conforming granules are sent to the next step as a finished product, while the off-spec granules are returned to the granulator via a belt conveyor for reprocessing.

- Finished Product Packaging: The final granules are packaged for storage, transport, and sale. The packaging materials are typically moisture-proof and durable.

IV. Advantages and Disadvantages

- Advantages:

- Good Granulation Effect: By setting the appropriate rotation speed and tilt angle, the raw materials can tumble continuously inside the machine, ensuring thorough mixing and uniform moistening. This results in a high forming rate and strong granules.

- Simple Operation: The system does not require a high level of technical expertise to operate. Its high degree of automation also saves labor costs.

- Wide Applicability: It can handle a variety of different organic raw materials, such as chicken manure, cow manure, and rapeseed meal, making it suitable for large-scale production.

- Superior Granule Quality: The produced granules have a loose and porous structure, which increases their contact area with the soil, facilitating nutrient release and microbial activity. The granules are also uniform in size and have a balanced nutrient distribution.

- Disadvantages:

- High Energy Consumption: Rotary drum granulators consume a lot of electricity and labor, especially during startup and shutdown.

- Dust Pollution: The tumbling and drying of materials during the production process can easily generate dust. The system requires effective dust collection equipment to reduce the impact of dust on the environment and the health of the operators.

V. Application Range of the Organic Fertilizer Rotary Drum Granulation Production Line

The organic fertilizer rotary drum granulation production line is a core piece of equipment for the resource utilization of organic waste and the industrial production of organic fertilizers. Its application range covers a wide array of fields, including agriculture, environmental protection, and horticulture.

- Agricultural Planting

- (1) Large-Scale Field Crops: It's suitable for producing base and top dressing fertilizers for large-scale field crops like wheat, corn, rice, and cotton. The granular organic fertilizer produced by drum granulation has balanced nutrients and a slow-release property, which can increase soil organic matter content and improve soil fertility. It is particularly suitable for improving areas with soil compaction and declining fertility caused by long-term continuous cropping.

- (2) Economic Crops: For crops with high quality requirements, such as fruits, vegetables, tea, and Chinese medicinal herbs, the production line can convert raw materials like animal manure and straw into odorless, easily absorbed granular fertilizer. This reduces chemical fertilizer residues, improves product quality, and meets the needs of green cultivation.

- Horticulture and Landscaping

- (1) Garden and Flower Planting: In flower and nursery cultivation, granular organic fertilizer allows for precise control of the nutrient release rate, preventing seedling burn. It is well-suited for the growth cycles of various flowers and seedlings like roses, orchids, and succulents, enhancing their ornamental value.

- (2) Urban Landscaping and Landscape Engineering: Used for park lawns, roadside green belts, and scenic area vegetation maintenance, granular fertilizer is easy to apply mechanically. It can also improve the water and nutrient retention capacity of urban soil (e.g., soil amended with construction waste), lowering the cost of landscaping maintenance.

- Organic Waste Resource Utilization

- (1) Animal Waste Treatment: For manure from livestock farms, such as pig, chicken, and cow manure, the rotary drum granulation production line enables the conversion of "manure waste into organic fertilizer." This solves the problem of livestock pollution, while the resulting granular fertilizer can be a valuable by-product.

- (2) Agricultural and Industrial Organic Waste Utilization: It can process organic waste like straw, mushroom residue, medicinal herb residue, distiller's grains, and food processing waste. It turns waste that is difficult to use directly into standardized granular fertilizer, achieving a "waste-to-fertilizer" circular economy model.

- Large-Scale Organic Fertilizer Production

- (1) Organic Fertilizer Production Companies: As a mainstream granulation equipment, the rotary drum granulation production line can meet the needs of large-scale production companies. The resulting granular fertilizer has good flowability and is easy to store and transport. It can be sold in various forms, such as bagged or in bulk, supplying the commercial fertilizer market.

- (2) Self-Production for Cooperatives and Planting Bases: Large agricultural cooperatives, family farms, and planting bases can use small-scale rotary drum granulation lines to process their own organic waste on-site, producing organic fertilizer for their own use. This lowers fertilizer procurement costs and creates a closed loop of "crop and livestock integration."

- Ecological Agriculture and Special Cultivation Models

- (1) Organic Agriculture Certification: The process meets the naturalness requirements for fertilizers in organic agriculture. The granular organic fertilizer can be a core fertilizer for organic farming, helping agricultural products obtain organic certification and increasing their market premium.

- (2) Saline-Alkali and Barren Soil Improvement: The organic matter and beneficial microbial communities in the granular organic fertilizer can improve the structure of poor quality soils like saline-alkali or sandy soils. This enhances the soil's buffering capacity and provides basic fertility to support vegetation recovery.

In short, the organic fertilizer rotary drum granulation production line, with its wide adaptability to raw materials, large-scale production efficiency, and versatile products, has become a key link connecting organic waste treatment and the development of green agriculture, playing an important role in promoting agricultural sustainability and environmental management.

VI. How to Choose an Organic Fertilizer Rotary Drum Granulation Production Line

Choosing a rotary drum granulation production line for organic fertilizer is crucial, as it directly impacts product quality, production efficiency, and operating costs. Here is a detailed guide on how to select the right line from several key perspectives.

- Define Production Needs and Scale First, you need to be clear about your production needs and scale. Consider the expected annual output, as this is the basis for determining the line's capacity. If you plan to produce less than 10,000 tons per year, a small-scale line is a good choice. For 10,000-50,000 tons per year, a medium-scale line is suitable, and for over 50,000 tons, you'll need a large-scale line. You should also define your product positioning—whether you're producing a general-purpose organic fertilizer or a specialty one for specific crops. Different products have different requirements for granule size, hardness, and other indicators, which will affect the line's configuration.

- Understand Raw Material Characteristics Raw material characteristics are a crucial basis for selecting a production line. Different organic fertilizer raw materials, such as animal manure, straw, or kitchen waste, have varying moisture content, organic matter content, and viscosity. For materials with high moisture content, you'll need to add dewatering equipment before granulation. More viscous materials may require the addition of a conditioning agent to ensure a good granulation effect. Therefore, before choosing a production line, you should conduct a comprehensive analysis of the physical and chemical properties of the raw materials you will use.

- Selecting the Core Equipment: The Rotary Drum Granulator The rotary drum granulator is the core of the production line, and its selection is particularly critical. Pay attention to the following parameters:

- (1) Drum Diameter and Length: Generally, the larger the diameter and length, the higher the production capacity. However, you should choose a size that is appropriate for your site and capacity needs, as bigger isn't always better.

- (2) Rotation Speed: The rotation speed affects the material's retention time inside the drum and the granulation effect. If the speed is too fast, the material may be discharged before it has fully agglomerated, resulting in uneven granules. If the speed is too slow, production efficiency will be low. You must choose an appropriate speed based on your raw material characteristics and granule requirements.

- (3) Tilt Angle: The tilt angle of the drum determines the material's movement speed inside the drum. If the angle is too steep, the material will move too quickly and there won't be enough time for granulation. If the angle is too shallow, the material will accumulate, affecting granulation efficiency. The tilt angle is typically between 2° and 5°.

- (4) Inner Lining Material: The inner lining material directly affects the granulator's service life and granulation effect. Common materials include rubber plates and stainless steel plates. Rubber plates have good wear resistance and shock absorption, making them suitable for more viscous materials. Stainless steel plates are corrosion-resistant, making them suitable for materials containing corrosive components.

- Choosing Ancillary Equipment In addition to the core rotary drum granulator, the selection of ancillary equipment is also important, as they form a complete production line together.

- (1) Fermentation Equipment: Organic fertilizer production requires the raw materials to be fermented and decomposed first. The choice of fermentation equipment depends on the amount of raw material and the fermentation process, with common options including trough compost turners and windrow compost turners.

- (2) Crushing Equipment: Fermented raw materials need to be crushed to a certain particle size for granulation. The selection of crushing equipment should consider the hardness of the raw material and the required particle size after crushing, with options like hammer crushers and cage crushers.

- (3) Drying Equipment: Granulated particles have a high moisture content and need to be dried. The choice of drying equipment depends on the moisture content of the granules and the production capacity. Rotary dryers and fluidized bed dryers are commonly used.

- (4) Cooling Equipment: Dried granules have a high temperature and need to be cooled before screening and packaging. The type of cooling equipment, such as a rotary cooler, must have a cooling efficiency that matches the dryer and subsequent screening equipment.

- (5) Screening Equipment: Screening equipment is used to sift out granules of the correct size. Off-spec granules are returned for re-granulation. You should choose a machine with high screening efficiency and accuracy, such as a vibrating screen.

- (6) Packaging Equipment: Select appropriate packaging equipment based on your product's packaging requirements, such as an automatic packaging scale, which can improve packaging efficiency and ensure accurate weights.

- Consider the Level of Automation The level of a production line's automation affects production efficiency and labor costs. A highly automated line can provide automatic control from raw material input to finished product packaging, reducing manual operation and improving production stability, though the initial investment is higher. For small production companies, a semi-automated line can lower costs. For large companies or those seeking high-efficiency production, a fully automated line is recommended.

- Investigate the Equipment Manufacturer Choosing a reliable equipment manufacturer is key to ensuring the quality of the production line and after-sales service. You should investigate the manufacturer's production strength, technical level, market reputation, and after-sales service system. You can visit the manufacturer's production workshop to understand their manufacturing process and equipment quality, check their customer cases to see how their equipment performs in actual production, and ask about their after-sales service, such as whether they provide timely equipment installation, debugging, personnel training, and maintenance.

- Calculate Costs and Benefits When choosing a production line, you should conduct a comprehensive cost calculation, including equipment acquisition costs, site construction costs, raw material costs, energy costs, and labor costs. At the same time, you should forecast the product's market price and sales volume to evaluate the return on investment and payback period. When choosing a line with a high cost-performance ratio, you should consider not only the initial investment but also long-term operating costs and economic benefits.

- Pay Attention to Environmental Requirements With the growing awareness of environmental protection, environmental regulations are becoming stricter. When choosing a production line, you must ensure it complies with national and local environmental standards. The line should be equipped with corresponding environmental protection equipment, such as waste gas treatment, wastewater treatment, and dust collection systems, to reduce the environmental pollution caused by the production process.

In conclusion, choosing an organic fertilizer rotary drum granulation production line requires a comprehensive consideration of production needs, raw material characteristics, equipment performance, automation level, manufacturer strength, cost-benefit analysis, and environmental requirements. By conducting a thorough analysis and comparison, you can select the most suitable production line for your specific situation and provide a strong guarantee for your organic fertilizer production.

Tai'an Hongxin Environmental:

Supply of High-Quality and Efficient Fertilizer Production Equipment, Straw Processing Equipment, Waste Treatment Equipment and Mining Equipment. If you are looking for fertilizer production equipment and production lines, feel free to contact us at any time.- Whatsapp(Tel): + 86 139-0548-5429( Mr. Li)

- E-mail: tahongxin@gmail.com