Description

- I. Basic Composition and Workflow

- II. Equipment Advantages

- III. Key Equipment: The Pan Granulator

- IV. Features of the Organic Fertilizer Pan Granulation Production Line

- V. Application Range of the Organic Fertilizer Pan Granulation Production Line

- VI. Key Selection Criteria for an Organic Fertilizer Pan Granulation Production Line

An organic fertilizer pan granulation production line is a system of equipment used to process organic materials into granular organic fertilizer. Here is a detailed introduction to its components and process.

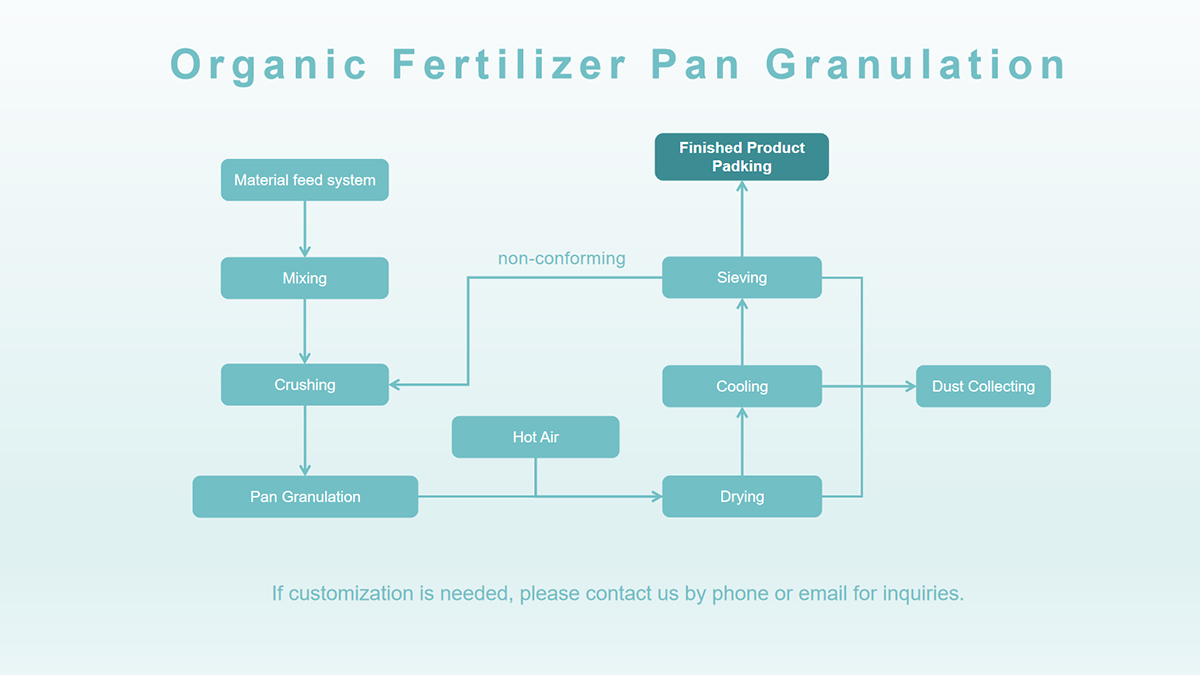

I. Basic Composition and Workflow

- Raw Material Pre-treatment: A crusher is used to break down large raw materials like animal manure and straw to ensure the material entering the granulation stage has an appropriate particle size. Auxiliary materials such as clay or humic acid are also added to adjust nutrients and control moisture content to 20%-30%.

- Mixing: A twin-shaft paddle mixer or a vertical pan mixer is used to thoroughly mix all the pre-treated materials, preventing clumping. Mixing time is generally 5-10 minutes, with a required mixing uniformity of ≥95%.

- Pan Granulation: The pan granulator is the core equipment. Its tilt angle is typically between 45°-55° and its rotation speed is 15-30 rpm. The materials roll within the pan under the combined forces of friction, centrifugal force, and gravity. A small amount of water or binder, such as a humic acid solution, is sprayed to promote the formation of granules.

- Drying and Cooling: A rotary dryer heats the wet granules to 50-60°C (122-140°F) to reduce their moisture content to 10%-15%. The granules are then cooled to room temperature using natural or forced air to prevent caking.

- Screening and Grading: A vibrating screen with a mesh size of 2-5mm is used to separate the合格 granules (those with a particle size of 2-5mm). Fines are returned to the mixing process, while oversized particles are crushed and re-granulated.

- Coating Treatment: A coating machine adds an anti-caking agent, such as talc, and/or slow-release agents like resins or sulfur, to improve the granule surface's smoothness, reduce nutrient volatilization, and ensure the granules are uniformly coated as they tumble in the rotating drum.

- Finished Product Packaging: An automatic packaging machine packages the product into specified sizes, such as 25kg or 50kg bags, and labels them with information like nutrient content, production date, and shelf life.

II. Equipment Advantages

- Simple Operation: The pan granulator has a relatively simple structure, making operation, maintenance, and repair easy. This reduces the labor intensity and technical requirements for operators.

- Good Granulation Effect: The machine can precisely adjust the pan's rotation speed and tilt angle based on the material's characteristics, ensuring uniform granulation. The granulation rate can exceed 90%, and the granules have good density and stability.

- Wide Applicability: It is suitable for granulating a wide range of organic raw materials, including animal manure, sugar mill filter mud, domestic waste, urban sludge, crop straw, mushroom residue, and traditional Chinese medicine residue.

- Adjustable Production Scale: By reasonably adjusting equipment parameters like pan diameter, rotation speed, and tilt angle, the line can be adapted to different production scales, from small-scale experimental production to large-scale continuous production.

- Eco-Friendly and Energy-Saving: Compared to traditional granulation methods, the pan granulator has lower energy consumption and produces almost no wastewater or exhaust gas during production, aligning with modern green production principles.

III. Key Equipment: The Pan Granulator

- Structure: The main components include the pan, a large gear, a small gear, a transmission part, a frame, a base, a scraper frame, and an angle adjustment device.

- Working Principle: The main working part of the pan granulator is a rotating, tilted pan. Powdered organic fertilizer is conveyed by a belt to the pan, and under conditions of proper moisture, it continuously rolls to form granular fertilizer due to centrifugal force, friction, and gravity. The granules are then discharged through the outlet.

IV. Features of the Organic Fertilizer Pan Granulation Production Line

The organic fertilizer pan granulation production line is a core equipment combination for processing organic fertilizers. It offers significant advantages due to its unique technical principles and structural design. Its main features are:

- Simple Structure and Easy Operation The core equipment, the pan granulator, uses a tilted pan structure with a simple, compact design and few components. During operation, you can control the granulation process by simply adjusting parameters like the pan's tilt angle (usually 30°-50°), rotation speed (10-30 rpm), and feed rate. This makes the learning curve low; regular operators can become proficient with short-term training, which significantly reduces labor costs.

- Strong Raw Material Adaptability and Wide Application Range This line can process a wide variety of organic fertilizer raw materials, including animal manure (pig, chicken, etc.), composted straw, municipal sludge, medicinal herb residue, mushroom residue, and other organic wastes. It has strong adaptability to the moisture content (suitable range 25%-40%) and particle size of the raw materials. It can granulate materials without extensive pre-treatment, making it especially suitable for complex mixed organic raw materials and meeting the diverse needs of different regions.

- Excellent Granule Quality and Stable Physical Properties With the combined action of centrifugal force, friction, and gravity generated by the rotating pan, materials form granules through a "snowballing" agglomeration process. The final granules have high roundness, a smooth surface, and uniform particle size (controllable between 2-6mm). The granules have moderate compressive strength (typically 3-8N), are not easily broken, and have good flowability, making them easy to screen, package, and apply in the field. This also facilitates the slow release of nutrients into the soil.

- Low Energy Consumption and Economical Operation Costs Compared to processes like rotary drum granulation and extrusion granulation, the pan granulator has lower power requirements (a single motor is typically 5.5-15kW), which can reduce unit product energy consumption by 20%-30%. The equipment investment cost is also low, making it especially suitable for small and medium-sized organic fertilizer production companies. The line has few wear parts (mainly the pan liner), a long replacement cycle, and low maintenance costs, making long-term operation highly economical.

- Continuous, Stable, and Controllable Production The production line can achieve a continuous, automated flow of feeding, granulation, and discharging. When combined with upstream fermentation and crushing equipment and downstream drying and cooling systems, it can form a closed-loop production system. The hourly output of a single pan granulator can be 0.5-5 tons. Production capacity can be flexibly increased by combining multiple machines to meet different scales of production. The granulation rate is high (typically ≥85%), and production stability is strong.

- Good Environmental Performance and Easy to Achieve Clean Production The granulation process produces very little dust. A simple dust collection device can be added above the pan to further control dust pollution. The production line has no wastewater discharge, and materials utilize moisture efficiently during granulation, which reduces energy consumption and waste gas emissions during the subsequent drying stage. This aligns with environmental policies for clean organic fertilizer production.

- Adjustable Granule Size to Meet Diverse Needs By adjusting parameters like the pan's tilt angle, rotation speed, raw material moisture, and binder addition, you can flexibly control the granule size. This allows for the production of medium-sized granules suitable for large-scale field crops as well as small-sized granules for fruits, vegetables, and flowers, meeting the personalized needs of different crops and application scenarios.

V. Application Range of the Organic Fertilizer Pan Granulation Production Line

The organic fertilizer pan granulation production line is a core equipment combination for the resource utilization of organic waste and the production of organic fertilizers. Its application range is wide, covering agriculture, environmental protection, and animal husbandry. Specifically, it can be divided into the following categories:

- Raw Material Processing

- (1) Agricultural Organic Waste: It can process various agricultural organic wastes from production, such as crop stalks (corn, wheat, rice husks), animal manure (chicken, cow, sheep, etc.), edible mushroom residue, and traditional Chinese medicine residue. Granulation allows for waste reduction, harmlessness, and resource recovery.

- (2) Industrial Organic Waste Conversion: It is suitable for processing industrial organic by-products like food processing waste (distiller's grains, vinegar residue, bean curd residue, fruit pulp), slaughterhouse waste, furfural residue, and cassava residue, converting them into high-value organic fertilizer granules.

- (3) Municipal Organic Waste Resource Recovery: It can be used to process and granulate kitchen waste, municipal sludge, and landscaping waste (dead leaves, grass clippings) to alleviate the environmental pressure of landfilling or incinerating urban organic waste.

- Industry Application Scenarios

- (1) Organic Fertilizer Production Companies: It serves as a core production line for small to large-scale organic fertilizer plants, capable of producing pure organic fertilizer granules, organic-inorganic compound fertilizer granules, and other products to meet the needs of different crops and soils.

- (2) Livestock Farming Companies: It provides a manure treatment solution for large-scale farms, converting animal manure into organic fertilizer granules, and realizing a circular agriculture model of "animal farming - manure treatment - crop planting."

- (3) Agricultural Cooperatives/Farms: It is suitable for large-scale planting bases to build their own organic fertilizer production lines on-site, processing farm waste and manure to produce organic fertilizer for their own use, which lowers fertilization costs and improves product quality.

- (4) Environmental Engineering: It is used in organic solid waste treatment projects, for example, for the granulation and solidification of sludge from landfill leachate treatment or organic residue from kitchen waste treatment. This facilitates subsequent transportation and resource recovery.

- Fertilizer Application Scenarios

- (1) Field Crop Cultivation: The produced organic fertilizer granules can be used as a base fertilizer for field crops like wheat, corn, and rice, improving soil aggregate structure and enhancing the soil's water and nutrient retention capacity.

- (2) Economic Crop Cultivation: It is suitable for economic crops like vegetables, fruit trees, tea, and traditional Chinese medicine. The slow-release organic fertilizer granules provide continuous nutrients, reduce the use of chemical fertilizers, and improve crop quality (e.g., taste, sweetness, storability).

- (3) Horticulture and Landscaping: It is used for the cultivation and maintenance of flowers, seedlings, and lawns. Organic fertilizer granules provide a gentle supplement of nutrients, preventing seedling burn, and also improving the breathability of potting soil and garden soil.

- (4) Soil Improvement Projects: In projects for improving saline-alkali land, restoring barren soil, or reclaiming mines, organic fertilizer granules can be used to adjust soil pH, supplement organic matter, and restore the soil's ecological function.

Additionally, this production line can be flexibly adjusted to match different types of organic waste and product requirements, playing an important role in ecological agriculture, green agriculture, and the circular economy.

VI. Key Selection Criteria for an Organic Fertilizer Pan Granulation Production Line

In the process of producing organic fertilizer, choosing the right pan granulation production line is crucial, as it directly affects production efficiency, product quality, and operating costs. Here is a detailed breakdown of the selection criteria from multiple perspectives:

- Control of Core Equipment Performance The pan granulator is the core equipment of the production line, and its performance directly determines the granulation effect. First, pay attention to the pan's diameter and tilt angle. The pan diameter is directly related to capacity. For a small production line, a pan with a diameter of about 1.5 meters can be used, while for a large one, a diameter of 2.5 meters or more is needed. However, this must be considered in conjunction with the site size. The tilt angle should generally be adjustable within the range of 30°-50°. This parameter affects the material's retention time and rolling effect within the pan; different material properties require different tilt angles to ensure uniform granule formation.The choice of pan material is also critical. Since organic fertilizer raw materials can be corrosive, the pan surface must be made of wear- and corrosion-resistant materials, such as stainless steel or special wear-resistant steel. This can effectively extend the equipment's service life and reduce maintenance costs. Furthermore, the ability to adjust the pan's rotation speed is essential. If the speed is too fast, the granules may become loose, while if it is too slow, it will lower the output. It must be able to be flexibly adjusted according to the material characteristics and granule requirements.

- Consideration of Ancillary Equipment Compatibility Organic fertilizer granulation involves multiple processes, and the compatibility of ancillary equipment directly affects the overall efficiency of the production line. The performance of pre-treatment equipment like the crusher and mixer is crucial. The crusher's output particle size must be up to standard. If the material is not crushed finely enough, it will result in uneven granulation. It's generally required that the raw material particle size reaches 80-100 mesh or more. The mixer must ensure that the material and additives (such as binders) are mixed uniformly to avoid localized differences that affect granulation quality.Post-processing equipment, including drying, cooling, and screening equipment, must be matched with the granulator's capacity. The dryer's processing capacity should be slightly higher than the granulator's to prevent material accumulation. The cooler must be able to quickly lower the temperature of the high-temperature granules to room temperature to prevent caking. The screening equipment must accurately separate off-spec granules to ensure the finished product has a uniform particle size, while returning the screened fines and large particles to the production line for reprocessing to increase raw material utilization.

Conveying equipment should be chosen based on the needs of each process to ensure smooth material transport, reduce residue and waste, and avoid excessive compression or breakage of the material during transport.

- Matching Capacity with Production Scale Capacity is a fundamental indicator for selecting a production line and must be calculated precisely based on actual production needs. First, determine your annual output target. Then, based on the number of working days per year and the daily working hours, calculate your daily and hourly output. When choosing a line, the rated capacity should be slightly higher than your actual needs to allow for a buffer, to handle peak production periods or a slight performance decline after minor equipment wear. Avoid blindly pursuing a high capacity that leads to idle equipment and waste, and also prevent insufficient capacity from affecting order delivery. A small farm or processing plant can choose a line with an hourly output of 1-3 tons, a medium-sized company can consider 5-10 tons per hour, and a large-scale producer will need a line with an hourly output of over 15 tons.

- Evaluate Raw Material Adaptability Different organic fertilizer raw materials (such as chicken manure, cow manure, straw, and medicinal residue) have varying characteristics, and the production line must have good material adaptability. For high-moisture raw materials (with moisture content over 60%), you'll need to configure efficient drying pre-treatment equipment to reduce the moisture content to the range suitable for granulation (generally 40%-50%). For fibrous materials like straw, you'll need to strengthen the crushing and mixing processes to ensure the fibers are uniformly dispersed. Some special raw materials may require the addition of a binder to aid granulation. The production line should be able to accommodate a binder addition system for precise metering and uniform mixing. If you plan to process a variety of raw materials, you should choose a versatile production line or an equipment configuration that can be easily adjusted to handle different materials.

- Choose the Level of Automation The level of automation affects production efficiency and labor costs. A production line with a PLC control system can achieve automated adjustments, such as automatically controlling the pan's rotation speed, feed rate, and water (or binder) addition. It can also use sensors to monitor parameters like material moisture and granule size in real-time, achieving closed-loop control and improving production stability. At the same time, the equipment should have a comprehensive fault alarm function so that it can provide timely warnings and shut down in the event of anomalies like motor overload or material blockage, allowing operators to quickly troubleshoot problems. For companies with a large production scale or high labor costs, a production line with a high degree of automation should be a priority.

- Energy Consumption and Environmental Compliance The line's energy consumption directly impacts operating costs. You should comprehensively evaluate the power parameters of all equipment and choose energy-efficient motors and machines. The choice of heat source for the drying equipment is especially critical. You can select biomass fuel, natural gas, or electric heating based on local energy supply to ensure heating efficiency while lowering energy costs. From an environmental perspective, the production line must comply with local environmental discharge standards. The waste gas produced during the drying process should be treated with dust collection and desulfurization equipment to prevent dust and harmful gas emissions. Wastewater generated during production should be treated and reused or discharged in compliance. Noisy equipment should have soundproofing to reduce its impact on the surrounding environment. Choosing equipment and a production line with environmental certifications can reduce the risk of environmental compliance issues.

- After-Sales Service and Quality Assurance After-sales service and quality assurance are vital for long-term, stable production. Choose a manufacturer with a good reputation and rich experience. Investigate their production qualifications, technical strength, and customer case feedback. The manufacturer should provide thorough pre-sales service, such as developing customized production line plans and providing site planning guidance. For after-sales service, clarify whether the manufacturer provides installation and debugging, operator training, the duration and scope of the warranty, and whether the supply of wear parts is timely. Quality after-sales service can help a company quickly resolve technical issues encountered during production and minimize equipment downtime.

- Cost Budget and Cost-Performance Evaluation Within your budget, balance equipment performance and price. Don't just focus on the equipment acquisition cost; you must also comprehensively consider long-term operating costs. Evaluate the equipment's service life, maintenance costs, and energy consumption to calculate its total life-cycle cost. Low-priced equipment may have issues like poor material quality, high energy consumption, and a high failure rate, which can increase long-term costs. When choosing a production line with a high cost-performance ratio, you need to compare the equipment configuration, performance parameters, and after-sales service of different manufacturers, and make a reasonable choice based on your production needs and budget.

- Site Adaptability Planning The production line layout must be compatible with the size and shape of the site. You must perform a detailed site measurement and planning before choosing the equipment. The equipment's installation dimensions must fit the site's space requirements, ensuring there is enough room for operation and maintenance between equipment. You also need to ensure smooth material flow, with a logical connection between the raw material storage area, finished product storage area, and the production line to reduce material transport distance and costs. Additionally, consider whether the site's power, water, and heating infrastructure can meet the production line's needs, to prevent installation and operation issues due to inadequate infrastructure.

- Ability to Guarantee Finished Product Quality The production line must be able to consistently produce organic fertilizer granules that meet quality requirements, including granule strength, uniformity, and moisture content. Granule strength must meet a certain standard to prevent breakage during transport and storage. High particle size uniformity can improve the product's market competitiveness. Moisture content must be controlled to between 10%-15% to prevent the granules from caking and deteriorating. When choosing a production line, you need to understand the equipment's ability to control finished product quality. You can ask the manufacturer to provide samples from actual production for testing or visit their demonstration production line to observe the quality of the finished product.

- Consideration of Safety Performance Production safety is the prerequisite for all company operations, and the production line must have comprehensive safety protection devices. Motors should have overload protection to prevent damage from excessive loads. The transmission parts must have protective covers to prevent operators from coming into contact with rotating parts and causing accidents. The equipment's electrical system must comply with electrical safety standards to prevent electrical hazards like leakage and short circuits. At the same time, the equipment should be easy to operate to avoid the risk of human error due to complex operating procedures. Choosing equipment with safety certifications ensures a safe and reliable production process.

Tai'an Hongxin Environmental:

Supply of High-Quality and Efficient Fertilizer Production Equipment, Straw Processing Equipment, Waste Treatment Equipment and Mining Equipment. If you are looking for fertilizer production equipment and production lines, feel free to contact us at any time.- Whatsapp(Tel): + 86 139-0548-5429( Mr. Li)

- E-mail: tahongxin@gmail.com