Description

A liquid fertilizer production line is a series of equipment used to produce liquid fertilizers that are applied by flushing or spraying. Here is a detailed introduction to it.

I. Production Line Composition and Functions

- Raw Material Storage System: This system is used to store various raw materials, such as macronutrients (nitrogen, phosphorus, and potassium), micronutrients, and other additives. It typically includes storage tanks of various sizes, often made of stainless steel or plastic to prevent contamination or corrosion of the materials.

- Metering and Batching System: This system precisely meters the amount of each raw material according to a preset formula. It uses metering equipment like electronic scales and flow meters, along with an automated control system, to achieve high-precision batching. For example, using METTLER TOLEDO load cells can ensure metering accuracy.

- Mixing and Agitation System: This system thoroughly mixes the metered raw materials in a mixing tank or reaction vessel. The agitator's rotation ensures uniform mixing. If needed, heating and pressurizing can also be applied to promote dissolution and reaction. The agitator's speed and shaft length can be adjusted according to production needs.

- Filtration System: After mixing, the liquid passes through filtration equipment like filter cloths, screens, and precision filters. This removes impurities, solid particles, and undissolved substances to ensure the purity of the final product.

- pH Value and Nutrient Adjustment System: This system uses acid-base regulators to adjust the pH value of the liquid fertilizer to meet the requirements for plant growth. Additionally, extra nutrients can be added or existing element concentrations can be fine-tuned according to the product formula.

- Filling and Packaging System: This system quantitively fills bottles, buckets, and other containers with the finished liquid fertilizer. It also seals, labels, and codes the containers. The filling equipment can be chosen based on packaging specifications and production speed. For example, using filling valves with both fast and slow speeds can ensure metering accuracy without affecting the overall filling rate.

- Control System: This system uses an automated control system, such as a PLC (Programmable Logic Controller), to monitor and control the entire production process. It automates raw material metering, mixing, filtration, and filling, which improves production efficiency and product quality stability while simplifying operation and management.

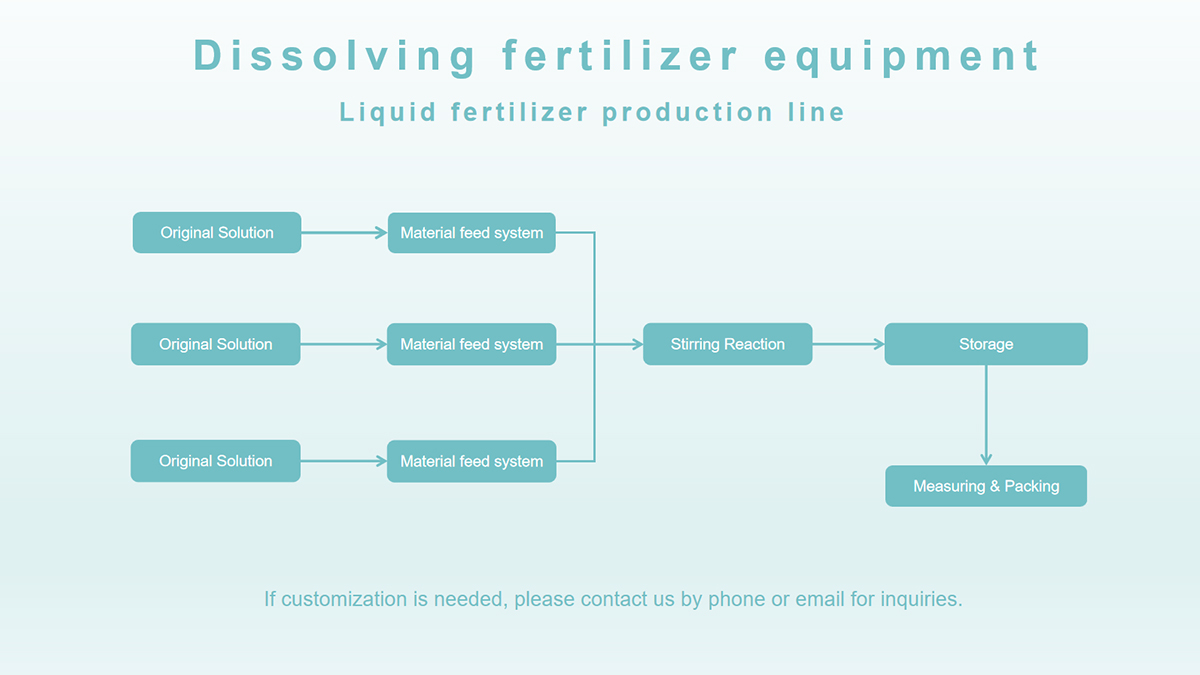

II. Working Process

- Raw Material Handling: The required raw materials are transported to the production workshop, where they are inspected and pre-treated to ensure their quality and purity meet the requirements.

- Formula Batching: According to the product formula, the different raw materials are precisely weighed and batched in a specific ratio using the metering and batching system.

- Dissolution and Mixing: The batched raw materials are added to the mixing tank or reaction vessel, where they are dissolved and thoroughly mixed through agitation, heating, or pressurizing to form a uniform liquid fertilizer.

- Filtration and Purification: The mixture is passed through the filtration system to remove impurities and solid particles, resulting in a pure liquid fertilizer.

- pH and Nutrient Adjustment: The pH of the liquid fertilizer is adjusted using corresponding regulators. Nutrients are added or adjusted as needed to ensure the product meets the expected quality standards.

- Packaging and Filling: The finished liquid fertilizer is portioned and filled into bottles, buckets, or other containers via the filling and packaging system. It is then sealed, labeled, and coded.

- Quality Inspection: Samples are taken from the finished product for quality inspection, including tests for concentration, pH, micronutrient content, and other performance metrics, to ensure the product meets all specifications.

- Storage and Shipment: The liquid fertilizer that meets quality standards is stored in appropriate containers or warehouses and shipped according to orders.

III. Features of the Liquid Foliar and Flush Fertilizer Production Line

As a core equipment system for the large-scale production of liquid fertilizers, the liquid foliar and flush fertilizer production line's design and operation are focused on efficiency, precision, and stability. It has the following key features:

- High Degree of Automation The production line integrates a smart control system that automates processes from automatic raw material metering and conveying to mixing, filtration, automatic filling, sealing, and labeling. The PLC control system allows for precise parameter settings, reducing manual intervention and human error while improving production efficiency. A single production line can achieve a daily capacity of tens to hundreds of tons.

- Strong Raw Material Adaptability The line is compatible with various liquid raw materials and additives, such as liquid NPK fertilizers, humic acid, amino acids, and micronutrient solutions. It is equipped with an adjustable raw material batching system that can flexibly adjust the input ratio of various materials according to different fertilizer formulas. This meets the production needs for functional liquid flush fertilizers (e.g., drought-resistant, growth-promoting, and quality-improving types).

- Continuous Production Process The closed-loop production process design seamlessly connects each stage via pipes, pumps, and other equipment, enabling continuous operation from raw material input to finished product output. This avoids the time loss from material transfer and waiting in traditional intermittent production, shortens the production cycle, and reduces material loss and contamination during transfer.

- Strict Precision Control The line is equipped with high-precision metering devices (e.g., electromagnetic flow meters, load cells) and online monitoring instruments. These provide real-time monitoring and feedback on key parameters such as raw material ratios, liquid levels, temperature, and pH. This ensures the final fertilizer's nutrient content, concentration, and uniformity are stable and up to standard, with an error controlled within ±1%, guaranteeing consistent product quality.

- Excellent Corrosion Resistance Core equipment like mixing tanks, reaction vessels, pipes, and filling heads are made of 304 or 316 stainless steel. Some components that come into contact with highly corrosive materials are lined with plastic or made of titanium alloy. This allows them to withstand long-term corrosion from acidic and alkaline materials, extending the equipment's service life and reducing maintenance costs.

- Outstanding Environmental and Safety Performance The production line has a complete set of environmental treatment units, including waste gas collection and purification devices and a wastewater recycling system, which reduces the emission of waste gases and liquids during production. It is also equipped with safety devices like overpressure protection, leak alarms, and emergency shutdowns to ensure a safe and controllable production process that complies with environmental and safety production standards.

- Flexible Adaptability to Diverse Needs The line has a modular design that can be customized and combined according to production scale (small, medium, large) and product specifications (different packaging capacities, different concentration levels). It supports quick switching of production formulas and adjustment of filling specifications (e.g., 5L/bucket, 20L/bucket, 1000L/IBC drum), which meets the production needs for small-batch, multi-product or large-scale, single-product orders and adapts to the diverse characteristics of the market.

- Convenient Smart Management Industrial IoT technology enables real-time collection, storage, and analysis of production data. Managers can remotely monitor the production status, view energy consumption data, and trace production records via terminal devices. The system has a self-diagnosis function for faults, which provides timely warnings of equipment anomalies, facilitates quick troubleshooting and repair, and improves production management efficiency.

- Energy-Saving and Low-Consumption Features The line uses high-efficiency, energy-saving motors, variable frequency speed control technology, and waste heat recovery devices to reduce energy consumption during production. By optimizing pipe design and minimizing material residue, it reduces raw material loss. This results in an overall production energy consumption that is 10-20% lower than that of traditional production lines, aligning with the concept of green production.

IV. Application Fields of the Liquid Foliar and Flush Fertilizer Production Line

Due to its ease of absorption, convenient application, and flexible formulas, liquid foliar and flush fertilizer is widely used in many agricultural sectors, effectively promoting crop quality, efficiency, and sustainable agricultural development.

- Field Crop Cultivation The production line plays an important role in the large-scale cultivation of field crops like corn, wheat, rice, and cotton. For the different nutritional needs of field crops at various growth stages, the line can customize fertilizers with appropriate ratios of nitrogen, phosphorus, and potassium, as well as formulas containing micronutrients like calcium, magnesium, and sulfur. By using supplementary fertilization combined with water-saving irrigation technologies like sprinkler and drip irrigation, it can quickly replenish nutrients for crops, promote photosynthesis and nutrient accumulation, and increase seed weight and yield. Additionally, liquid fertilizer reduces nutrient loss caused by traditional broadcast application of chemical fertilizers, which lowers pollution to the soil and water environment.

- Economic Crop Cultivation Economic crops like vegetables, fruit trees, and melons have more specific nutritional needs, and the liquid foliar and flush fertilizer production line is especially widely used in this field. For the fruiting stage of vegetables like tomatoes, cucumbers, and peppers, the production line can produce high-potassium liquid fertilizer to improve fruit quality, taste, and single fruit weight. For berry crops like strawberries and grapes, applying a liquid fertilizer containing humic acid and amino acids can promote uniform fruit coloration and sugar accumulation. In fruit tree cultivation, liquid fertilizer can be used as a supplementary fertilizer during key periods like before flowering and during fruit expansion to meet the concentrated nutrient demand of fruit trees and reduce flower and fruit drop.

- Facility Agriculture and Intensive Cultivation Intensive cultivation models in facility agriculture, such as greenhouses and multi-span greenhouses, provide an ideal application scenario for the liquid foliar and flush fertilizer production line. Crops in these facilities have high planting density, short growth cycles, and concentrated nutrient demands. Liquid fertilizer can be precisely applied through fertigation systems to achieve high nutrient utilization efficiency. The production line can quickly adjust fertilizer formulas to meet the diverse planting needs of different crops in the facilities (e.g., cherry tomatoes, lettuce, flowers). Moreover, liquid fertilizer is easy to meter and control, which reduces soil salinization problems caused by improper fertilizer application in facilities and helps maintain soil fertility.

- Specialty Planting and Horticulture The liquid foliar and flush fertilizer production line also holds an important position in specialty planting and horticulture, such as for flowers, nurseries, and lawns. In flower cultivation, liquid fertilizer can provide balanced nutrition, promote robust growth, abundant blooms, vibrant colors, and extend the flowering period. Seedlings in nurseries require a long-term, stable nutrient supply. The slow- and controlled-release liquid fertilizer produced by the line can slowly release nutrients to meet the needs of seedlings at different growth stages, which improves seedling survival rates and quality. For golf courses and park lawns, spraying liquid fertilizer can give the lawn a vibrant color and uniform texture and enhance its resistance to stress.

- Specific Environments and Soil Improvement The application of the liquid foliar and flush fertilizer production line has significant advantages in agricultural planting in special environments like arid/semi-arid regions and saline-alkali land. In arid regions with scarce water resources, liquid fertilizer, combined with water-saving irrigation technologies, can improve water and fertilizer utilization and ensure crop growth under limited water conditions. For saline-alkali land with poor soil structure and low nutrient availability, the production line can produce liquid fertilizer containing soil conditioners. By supplementing substances like organic acids and humic acids, it can improve soil aggregate structure, lower soil salinity, increase nutrient availability, and promote crop growth in saline-alkali environments.

- Ecological and Green Agriculture With the development of ecological and green agriculture, the application of the liquid foliar and flush fertilizer production line is increasing. The production line can use raw materials like organic fertilizers from plants and animals and biological agents to produce organic liquid flush fertilizers that meet the planting needs of green food and organic agricultural products. These liquid fertilizers not only provide nutrition for crops but also improve the soil's micro-ecological environment, increase the number of beneficial microorganisms, and enhance soil fertility, achieving an ecological cycle and sustainable development for agriculture.

V. Key Equipment Selection Criteria

In agricultural modernization, liquid foliar and flush fertilizer is widely used due to its fast-acting and highly efficient nature. An efficient and stable production line is the core of ensuring the quality and output of liquid foliar and flush fertilizer. Here are the selection criteria for a liquid foliar and flush fertilizer production line, broken down from multiple perspectives, to provide a reference for business decisions.

- Precise Production Needs Assessment Production needs are the primary basis for selecting a production line. This must be clearly defined from the two aspects of production scale and product type.

- (1) Production Scale: This should be based on your company's short-term plan and long-term development strategy. A small-scale trial line is suitable for startups or new product development. Its annual output is typically below 1,000 tons, and the equipment configuration is small and flexible, such as a 500L batch mixing tank and semi-automatic filling equipment. A medium-sized line generally has an annual output of 1,000-5,000 tons and needs to be equipped with a continuous dissolution system and an automatic metering device to meet regular medium-scale production. A large-scale line has an annual output of over 5,000 tons and needs to use a fully automatic control system, a large tank farm, and a high-speed filling line to achieve continuous large-scale production and lower the cost per unit.

- (2) Product Type: This determines the core process configuration of the production line. Liquid macronutrient fertilizers (e.g., NPK types) require high demands for dissolution and mixing uniformity, so they need to be equipped with powerful mixing equipment and online detection devices. Micronutrient liquid fertilizers need to focus on the chelation reaction conditions of the raw materials and may require a temperature-controlled reaction vessel and equipment for testing chelation effects. Liquid fertilizers containing humic acid and amino acids, on the other hand, need to consider equipment for raw material pre-treatment (e.g., activation of humic acid, hydrolysis of amino acids) and the precision of the filtration and purification system.

- Process Adaptability Evaluation The liquid foliar and flush fertilizer production process includes raw material dissolution, mixing and reaction, filtration and purification, metering and filling, and sterilization and preservation. The production line must be a precise match for the process needs.

- (1) Raw Material Dissolution: For hard-to-dissolve raw materials (e.g., some phosphates, micronutrient salts), you need to configure heating devices (e.g., jacketed heating mixing tanks), ultrasonic-assisted dissolution equipment, or high-pressure homogenizers to improve dissolution efficiency. Easily dissolvable raw materials can be dissolved with ambient temperature stirring, but the agitator's speed and layout must be reasonable to prevent raw material sedimentation.

- (2) Mixing and Reaction: Choose the right equipment based on the reaction type. For physical mixing fertilizers, you can use a regular mixing tank to ensure the materials are uniformly mixed. For chemical reaction types (e.g., chelation reaction, acid-base neutralization), you need to be equipped with a reaction vessel with a pH monitoring and temperature control function to precisely control parameters like reaction time, temperature, and pressure.

- (3) Filtration and Purification: This directly affects the product's purity. You need to choose filtration equipment based on the impurity particle size. For preliminary filtration, you can use a bag filter to remove large particle impurities. For fine filtration, you need to use a precision filter cartridge (e.g., 5-10μm precision) or a membrane filtration system to prevent clogging of drip irrigation equipment and ensure a good fertilization effect.

- (4) Metering and Filling: This needs to balance precision and efficiency. For small-sized packaging (e.g., 1-20L), a fully automatic piston filler is suitable, and the metering accuracy can be controlled to within ±1%. For large-sized packaging (e.g., 200L drums, IBC drums), you need to be equipped with weighing-type filling equipment and also include anti-drip devices and automatic capping mechanisms.

- (5) Sterilization and Preservation: You need to choose a process based on the product's shelf-life requirements. For short-term preservation (within 3 months), you can use UV sterilization or ozone sterilization. For long-term preservation (over 6 months), you need to combine pasteurization (at 60-80°C for 30 minutes) with preservative additives. The production line needs to be equipped with corresponding sterilization equipment and a temperature control system.

- Equipment Performance and Quality Control Equipment performance and quality are the foundation of a production line's stable operation. You need to focus on the materials, automation level, energy consumption, and environmental friendliness.

- Equipment Materials: The materials must meet corrosion resistance requirements. Liquid foliar and flush fertilizers are mostly acidic or alkaline, so the equipment parts that contact the materials (e.g., mixing tanks, pipes, valves) must be made of 304 or 316 stainless steel to prevent material corrosion from causing product contamination and equipment damage. Wear parts like seals and gaskets should be made of food-grade silicone or fluoroelastomer that are resistant to chemical corrosion.

- Automation Level: This affects production efficiency and stability. Basic automation should include automatic control of raw material metering, mixing time, and temperature. Advanced automation can be equipped with a PLC control system to enable interconnected operation of different pieces of equipment and automatic fault alarms. A smart production line can also be combined with IoT technology to achieve real-time monitoring of production data, remote operation, and smart scheduling of production plans.

- Energy Consumption and Environmental Friendliness: This must comply with national requirements. Prioritize energy-saving equipment, such as variable frequency motors and high-efficiency heat exchangers, to reduce electricity and heat energy consumption. The wastewater generated during production needs to be equipped with a wastewater treatment device to meet emission standards. The storage area for volatile raw materials needs to have a waste gas collection and treatment system to prevent environmental pollution.

- Compliance Requirements Check The production line and products must comply with relevant standards and regulations to avoid compliance risks.

- Product Quality: The product quality must comply with national standards, such as "Liquid Fertilizer" (NY/T 1106) and "Macronutrient Water-Soluble Fertilizer" (NY 1107). The production line must be equipped with necessary testing equipment, such as pH meters, conductivity meters, and particle size analyzers, to ensure product indicators are up to standard.

- Production Safety: The production safety must meet industry standards. The equipment needs to be equipped with safety devices like overload protection, leakage protection, and pressure relief valves. The storage area for flammable and explosive raw materials must comply with fire and explosion-proof requirements and have fire-fighting facilities and warning signs.

- Equipment Qualifications: Equipment qualifications must be complete. Key equipment (e.g., pressure vessels, metering instruments) must have nationally recognized production licenses and verification certificates. The production line's design and installation must comply with relevant standards, such as the "Design Code for General Layout and Transportation of Chemical Plants."

- After-Sales Service and Supply Chain Assurance Good after-sales service and a stable supply chain are a guarantee for the long-term stable operation of the production line.

- Supplier Services: The supplier must provide comprehensive services, including equipment installation, debugging, operator training, and technical guidance. Be clear about the after-sales service response time and warranty period to ensure that equipment faults can be handled in a timely manner. Prioritize suppliers with local service points to reduce maintenance costs and time.

- Spare Parts Supply: Spare parts must be supplied in a timely and stable manner. The supplier should provide a list of common spare parts and supply channels to ensure that wear parts (e.g., filter elements, seals, sensors) can be quickly purchased. You should also find out the suppliers of the equipment's core components and evaluate the stability of their supply chain to prevent production line shutdowns due to a shortage of core parts.

- Technical Support: The supplier must have continuous technical support capabilities and be able to provide equipment modification plans based on industry development and company needs. They should also regularly organize technical exchanges and training to help companies master the latest production technologies and equipment maintenance knowledge.

- Comprehensive Cost-Effectiveness Analysis On the premise of meeting production needs, you need to conduct a comprehensive cost-effectiveness analysis to maximize cost performance.

- Initial Investment Cost: This includes the cost of equipment purchase, factory construction, and pipeline installation. You need to compare the quotes and configurations of different suppliers to avoid over-investment or insufficient configuration. Also, consider the equipment's service life and calculate the depreciation cost per unit of time.

- Operating Costs: This covers raw material consumption, energy costs, labor costs, and maintenance costs. A highly automated production line can reduce the number of employees, but the initial investment is higher. You need to calculate the payback period based on the production scale. Equipment with low energy consumption may have a higher purchase cost, but it can save a significant amount of energy costs in the long run.

- Hidden Costs: You need to estimate hidden costs in advance, such as downtime losses due to equipment failure, rework costs from off-spec products, and fines from non-compliance with environmental standards. Choosing a production line with high reliability and environmental compliance can reduce the risk of hidden costs.

- Flexibility and Scalability Considerations The production line must have a certain degree of flexibility and scalability to adapt to business development and market changes.

- Product Switching Flexibility: The equipment must be able to adapt to the production of products with different formulas and specifications, for example, adjustable mixing tank volumes and filling equipment that can quickly change filling heads and packaging specifications. The control system needs to have a formula storage function to enable quick recall of production parameters for different products.

- Capacity Expansion Convenience: The production line design needs to reserve a certain amount of space and interfaces for equipment installation to facilitate later additions or capacity upgrades. Core equipment (e.g., mixing system, filling line) must have a modular design so that capacity can be increased by adding modules.

- Site Adaptability Planning The production line layout must be compatible with the site conditions to ensure smooth production.

- Factory Space: The factory space must meet the equipment installation requirements. You need to reasonably plan the length, width, and height of the factory based on the equipment size and operational space needs. Consider the access for equipment entry and exit and maintenance space to avoid a crowded layout that affects operation and maintenance.

- Utilities: The factory's utility conditions must be a match. Check whether the power capacity meets the total power demand of the equipment and whether the voltage stability meets the requirements. The water supply and drainage system must be able to meet the needs for production water and wastewater discharge, and the water quality must meet the requirements of the production process. The supply of steam, compressed air, and other energy sources must be stable, and the pipeline layout must be reasonable.

In short, selecting a liquid foliar and flush fertilizer production line is a systematic project that requires a comprehensive consideration of production needs, process adaptability, equipment performance, compliance requirements, after-sales service, cost-effectiveness, flexibility, and site conditions. A company should conduct thorough research and evaluation based on its actual situation to choose the most suitable production line solution, laying a solid foundation for the stable production of liquid foliar and flush fertilizer and the company's long-term development.

Tai'an Hongxin Environmental:

Supply of High-Quality and Efficient Fertilizer Production Equipment, Straw Processing Equipment, Waste Treatment Equipment and Mining Equipment. If you are looking for fertilizer production equipment and production lines, feel free to contact us at any time.- Whatsapp(Tel): + 86 139-0548-5429( Mr. Li)

- E-mail: tahongxin@gmail.com