Description

The compound fertilizer spray granulation production line is a key piece of equipment used for producing compound fertilizers. Here is a brief introduction to its working principles, equipment composition, and production process.

I. Working Principle

- Atomization and Granulation: Molten urea or other solutions are fed by a high-pressure pump into specially designed atomizing nozzles, where they are atomized into fine droplets. These droplets come into contact with fine crystal nuclei inside a rotating drum. The droplets adhere to the surface of the nuclei, and under the effect of a high-temperature drying medium, they quickly complete a heat and mass exchange process, causing the granules to gradually grow in size.

- Rolling and Forming: Inside the rotary drum granulator, the material forms a rolling bed through the friction created by the machine's rotation. The compressive force from the rolling action and the adhesive force from the spraying cause the material to agglomerate into spherical granules.

II. Equipment Composition

- Raw Material Handling Equipment: This includes various storage tanks, conveyors, and elevators used for storing and transporting raw materials such as phosphoric acid, sulfuric acid, urea, phosphate rock powder, and potash. Examples include sulfuric acid solution storage tanks and urea elevators.

- Reaction and Mixing Equipment: Such as pre-reaction tanks, tubular reactors, and mixers, these allow for pre-reaction and thorough mixing of raw materials, ensuring full and uniform reaction. This provides an excellent material base for subsequent granulation.

- Main Granulator: The main piece of equipment is the spray drum granulator, which is the core of the production line. This is where the spraying, granulation, and initial drying processes take place.

- Drying and Cooling Equipment: The rotary dryer is used to further dry the granulated material and remove moisture. The rotary cooler uses natural or forced cool air to cool the dried granules, increasing their stability and strength for subsequent processing.

- Screening Equipment: Typically using a trommel screen, this equipment screens the cooled granules. Particles that meet the required size are selected as the final product. Oversized particles that don't meet the requirements are crushed by a crusher and returned to the granulator. Fine particles are returned and reused as crystal nuclei.

- Tail Gas Treatment Equipment: Equipment like cyclone dust collectors, bag filters, and labyrinth gravity settling chambers are used to treat dust and waste gases generated during the production process, reducing environmental pollution and ensuring emissions meet standards.

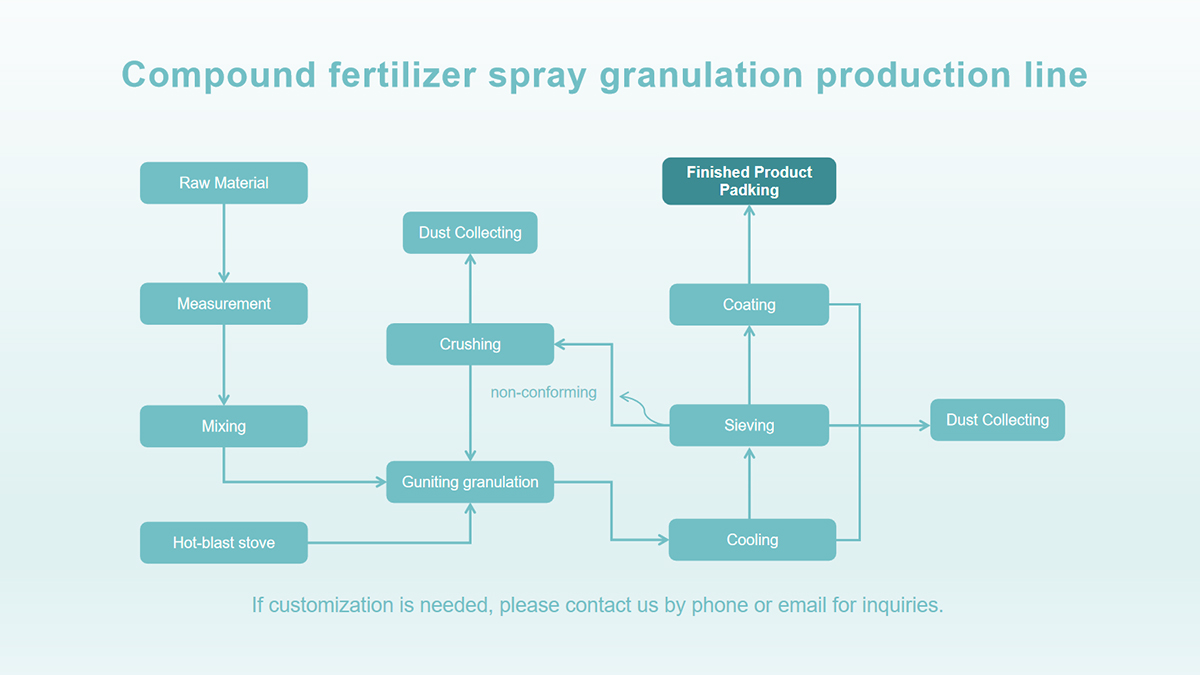

III. Production Process

- Raw Material Preparation: Various raw materials like urea, monoammonium phosphate (MAP), potassium chloride, and phosphate rock powder are proportioned according to a specific ratio and conveyed to their respective storage tanks or silos.

- Melting and Mixing: A portion of the urea is added to a urea melter and heated with steam or a thermal oil boiler to turn it into a liquid state. Simultaneously, other powdered raw materials like MAP, potassium chloride, and fillers are transported to weighing equipment. After weighing, the powdered materials are conveyed to a mixer for thorough blending.

- Spray Granulation: The molten urea slurry is pressurized by a special pump, atomized, and sprayed onto the material curtain inside the rotary drum granulator. It makes full contact with the powdered materials conveyed into the granulator. Under the combined effects of friction and compression from the machine's rotation and the adhesive force of the urea slurry, the materials agglomerate into spherical granules.

- Drying and Screening: The granulated material is then conveyed to a rotary dryer for drying before entering the screening equipment. Off-spec granules are returned to the corresponding processes for reprocessing.

- Cooling and Coating: The screened semi-finished granules are conveyed to a rotary cooler for cooling. The cooled, qualified product is then transported to a coating machine to form a protective film on the granule surfaces, which enhances their moisture resistance and anti-caking properties.

- Packaging and Warehousing: After coating, the compound fertilizer granules are transported to a fully automatic packaging scale for weighing and packaging, then stored in a warehouse.

IV. Features of the Spray Granulation Production Line

The spray granulation production line is a commonly used system for forming granular products in industries like fertilizer manufacturing. Its features are primarily reflected in its process principles, production efficiency, product quality, and application flexibility.

- Advanced Technology and Excellent Granule Forming The core principle of spray granulation is to atomize a raw material slurry using high-pressure nozzles. The atomized droplets fully contact and adhere to the recycled particles in a fluidized bed, gradually growing to form uniform granules. Granules produced this way have a smooth surface and high strength, are not prone to caking or breaking, and are easy to store, transport, and apply.

- Strong Raw Material Adaptability This production line has a wide adaptability to raw materials. It can process various nitrogen, phosphorus, and potassium fertilizer base materials, such as urea, MAP, DAP (diammonium phosphate), potassium chloride, and potassium sulfate. It can also use industrial by-products or waste (such as phosphogypsum and waste acids) as raw materials to produce compound fertilizers. This not only broadens the raw material sources but also achieves resource recycling, lowering production costs.

- High Nutrient Uniformity During production, raw materials are fully mixed into a slurry, ensuring an even distribution of nutrients. Through atomization and granulation, each granule carries a balanced amount of nutrients, avoiding problems of localized nutrient concentration or uneven distribution that can occur with traditional granulation methods. This results in a more stable fertilizing effect, meeting the balanced nutrient needs for crop growth.

- Continuous and High-Efficiency Production The spray granulation production line operates in a continuous production mode. The stages—from raw material pretreatment, slurry preparation, granulation, drying, and cooling to screening and packaging—are closely linked, enabling non-stop production. This continuous process significantly improves production efficiency and is suitable for large-scale industrial production, meeting high market demand for fertilizers and other products.

- Lower Energy Consumption and Better Environmental Performance Modern spray granulation production lines typically use an optimized hot air system for drying, which has higher thermal efficiency and effectively reduces energy consumption. The production line is also equipped with comprehensive waste gas and dust treatment devices, such as cyclone separators and bag filters, to collect and treat dust and harmful gases, reducing environmental pollution and meeting environmental regulations.

- High Degree of Automation The spray granulation production line widely adopts automated control technology. A PLC control system provides real-time monitoring and precise regulation of key parameters such as temperature, pressure, slurry concentration, and granule size. Automated control not only improves production stability and reliability, but it also reduces human error, lowers labor intensity, and enhances production management.

- Flexible Product Functionality This production line can flexibly adjust formulas to produce granular products with different nutrient contents and functions, based on market demand and crop characteristics. For example, it can add functional ingredients like micronutrients, humic acid, amino acids, or slow/controlled-release agents to produce specialized compound fertilizers or slow-release fertilizers. This meets the specific fertilization needs of different regions and crops, increasing the product's added value.

- Strong Equipment Integration The spray granulation production line is an integrated equipment system, covering multiple unit operations such as raw material handling, the granulation core, drying and cooling, and finished product processing. The units work together to form a complete production system. This high degree of integration makes the production line easy to install, debug, and maintain, and also allows for flexible configuration and expansion based on production scale and site conditions.

V. Application Fields of the Compound Fertilizer Spray Granulation Production Line

By spraying a concentrated slurry into a granulator to combine with recycled particles and then drying them into granules, the compound fertilizer spray granulation production line produces fertilizers with significant advantages like uniform nutrients, high granule strength, and good water solubility. It has wide applications in agriculture and related fields.

- Grain Crop Cultivation Fertilizers produced by the spray granulation line play a vital role in grain crop cultivation. For wheat, which requires various nutrients like nitrogen, phosphorus, and potassium, the spray granulated compound fertilizer provides a balanced and stable release of nutrients, supporting all stages of wheat growth, promoting tillering and grain filling, and effectively increasing thousand-grain weight and yield. According to statistics from a local agricultural department, wheat farmers who used this fertilizer saw an average yield increase of 10-15%. In corn cultivation, the fertilizer's good water solubility allows it to be easily absorbed by corn roots, meeting the high nutrient demand during critical periods like jointing and tasseling, reducing nutrient deficiency, and improving corn quality and yield.

- Economic Crop Cultivation Economic crops have more precise fertilizer requirements, which spray granulated compound fertilizer can effectively meet. Take cotton for example: its long growth cycle requires varying proportions of nitrogen, phosphorus, and potassium. The spray granulated compound fertilizer's formula can be adjusted to meet the specific needs of different growth stages, ensuring just the right nutrient supply, promoting more bolls, increasing boll weight, and improving cotton fiber quality and yield. In soybean cultivation, the phosphorus in this fertilizer can effectively promote the growth and reproduction of soybean root nodules, enhancing the plant's nitrogen fixation ability, which in turn increases soybean yield and improves quality.

- Fruit and Vegetable Crop Cultivation The advantages of spray granulated compound fertilizer are especially evident in fruit and vegetable cultivation. For vegetables like tomatoes and cucumbers, which have fast growth rates and high, concentrated nutrient demands, this fertilizer provides a rapid and balanced release of nutrients, meeting their needs during different stages like the seedling and fruiting periods. This leads to healthier plants, brighter-colored and better-tasting fruit, and a reduction in malformed produce. In fruit trees like apples and citrus, the fertilizer provides comprehensive nutrients, promoting flowering and fruiting, increasing fruit yield, and improving sugar content and flavor. An orchard that used this fertilizer saw its premium fruit rate increase by more than 20%.

- Special Soil Environment Improvement Spray granulated compound fertilizer can also be effective in challenging soil environments like saline-alkali or barren soils. In saline-alkali soil, the high pH can lead to nutrient fixation and low utilization. The high-strength granules of spray granulated fertilizer are less likely to break down in the soil, reducing unproductive reactions and increasing nutrient utilization. Additionally, soil amendments can be added to the fertilizer to gradually improve the soil structure. In barren soil, the fertilizer provides rich nutrients, increasing soil fertility and creating a good growing environment for crops.

- Large-Scale Farming and Ecological Agriculture Large-scale farms prioritize efficient and precise fertilization. The uniform granules of spray granulated fertilizer are well-suited for mechanized application, increasing efficiency and reducing labor costs. In ecological agriculture, the spray granulation line can produce fertilizers that combine organic and inorganic components, meeting the requirements of ecological farming, reducing environmental pollution from chemical fertilizers, and supporting sustainable agricultural development.

In summary, the fertilizer produced by the compound fertilizer spray granulation production line, with its superior characteristics, has important applications in grain crops, economic crops, fruits and vegetables, special soil improvement, and large-scale and ecological agriculture. It provides strong support for high-yield, high-quality agricultural development.

VI. Key Selection Criteria for a Compound Fertilizer Spray Granulation Production Line

Choosing a compound fertilizer spray granulation production line is crucial, as it directly impacts product quality, production efficiency, costs, and environmental compliance. Here are the key selection criteria from several important dimensions:

- Capacity Matching and Flexibility Capacity is the primary consideration. The production line must precisely match the company's actual needs. It's essential to determine the basic capacity based on market demand forecasts and long-term production plans to avoid wasting resources with a line that's too large or hindering production progress with one that's too small. The line should also have some flexibility to adapt to production fluctuations. Look at the operational stability at different loads, for example, if it can maintain good performance within 70-120% of its design capacity to handle changing market demands.

- Raw Material Adaptability and Process Stability Compound fertilizer raw materials vary widely in nitrogen, phosphorus, and potassium ratios, and their properties (e.g., moisture content, particle size, viscosity) can differ significantly, which all affect granulation. Therefore, the production line must have good raw material adaptability. Focus on the line's ability to handle special materials like high-nitrogen or high-viscosity raw materials, and whether it encounters issues like caking or difficult granulation. The controllable range of granule size is also a key indicator, as it must be able to meet the requirements of different product specifications. For process stability, assess the consistency of product quality—such as granule uniformity and strength—during long-term operation.

- Core Equipment Quality and Material Selection Equipment quality directly affects the line's operational stability and lifespan. For a spray granulation line, the quality of core equipment like the spray pump, granulator, and dryer is critical. Pay attention to the materials used for parts that come into contact with corrosive raw materials, such as the spray pump impeller and the granulator lining. These should be made of corrosion- and wear-resistant materials like stainless steel or special alloys to extend the equipment's lifespan and reduce maintenance costs. The brand of core components should also be considered; choosing reputable brands for motors, gear reducers, and other key parts ensures higher reliability and a lower chance of equipment failure. Additionally, manufacturing precision influences the production outcome; for instance, the speed control precision of the granulator directly affects granule uniformity.

- Energy Consumption Control and Environmental Compliance Given the current focus on energy conservation and emissions reduction, the line's energy consumption metrics are crucial. Look at the consumption of coal, electricity, and water per unit of product. Choosing an energy-efficient line will lower production costs. On the environmental front, national regulations for fertilizer manufacturers are becoming increasingly strict, so the production line must be equipped with comprehensive environmental protection facilities. Check for an efficient waste gas treatment system that can effectively handle dust, ammonia gas, and other pollutants generated during production. This may include technologies like cyclone separation, bag filtering, or ammonia gas recovery. The wastewater treatment system must also meet standards, ensuring that wastewater can be recycled or discharged in compliance. The line's environmental performance must meet local standards to avoid production interruptions or high remediation costs.

- Automation Level and Smart Management The level of automation directly impacts production efficiency and product quality stability. Choose a production line with a high degree of automation to reduce manual intervention and human error. Check if the control system is advanced and can automatically monitor and adjust key process parameters like temperature, pressure, flow rate, and liquid level. Does it have a comprehensive data monitoring and alarm function? Can it automatically provide early warnings and make linked adjustments when parameters like granulation temperature or pressure are abnormal? Furthermore, if the production line can integrate with enterprise management systems for smart management and data analysis, it will be even more beneficial for production optimization and management decisions.

- After-Sales Service and Spare Parts Assurance Production lines will inevitably experience breakdowns during long-term operation. Timely after-sales service and a sufficient supply of spare parts are essential to ensure the line runs smoothly. When choosing a line, assess the manufacturer's technical strength and after-sales service system. Find out about their response time for after-sales service and whether they can provide timely on-site repairs and technical support. Also, inquire about their spare parts supply, whether they have a sufficient stock of common parts, and the lead time and price for ordering parts. This will help reduce maintenance costs and minimize downtime risks.

- Return on Investment (ROI) and Long-Term Adaptability The price of different production line configurations can vary significantly. When choosing, don't just consider the initial investment cost. You must also calculate the ROI by factoring in capacity, energy consumption, and maintenance costs. Choose a line with a high cost-performance ratio to ensure the company can recoup its investment in a reasonable amount of time. The production line should also have long-term adaptability, allowing it to handle future changes like fertilizer product upgrades or stricter environmental standards. For example, is the line's design flexible enough for process upgrades? Can the equipment be easily modified and upgraded to meet the company's long-term development needs?

In conclusion, when selecting a compound fertilizer spray granulation production line, you must comprehensively consider capacity matching, raw material adaptability, equipment quality, energy consumption and environmental compliance, automation level, after-sales service, and ROI. A thorough evaluation of these factors will help you make the best choice to ensure the company's production efficiency and long-term success.

Tai'an Hongxin Environmental:

Supply of High-Quality and Efficient Fertilizer Production Equipment, Straw Processing Equipment, Waste Treatment Equipment and Mining Equipment. If you are looking for fertilizer production equipment and production lines, feel free to contact us at any time.- Whatsapp(Tel): + 86 139-0548-5429( Mr. Li)

- E-mail: tahongxin@gmail.com