Description

A rotary drum cooler is an industrial machine that uses a rotating cylinder to exchange heat with a cooling medium, rapidly cooling down high-temperature materials. This document introduces its structure, working principle, and applications.

1. Structural Components

- Cylinder: This is the main part of the rotary cooler, typically a cylindrical drum installed at a slight incline. Its inner wall is fitted with lifting flights. As the cylinder rotates, it tumbles and moves the material, ensuring full contact with the cooling medium for effective heat exchange.

- Drive System: This system, composed of a motor, reducer, and gear ring, powers the cylinder's rotation. It ensures the drum rotates at a steady, preset speed, allowing for uniform cooling of the material.

- Feeding and Discharge Devices: These include an inlet and outlet. High-temperature material enters the cylinder through the inlet, and after being cooled, it exits through the outlet. The design of these ports ensures a smooth flow of material and prevents the cooling medium from leaking.

- Lifting Flights: Installed on the inner wall of the cylinder, their purpose is to lift and cascade the material, creating a uniform "curtain of material" inside the drum. This increases the contact surface area between the material and the cooling medium, boosting cooling efficiency.

- Cooling Medium Supply System: Depending on the cooling method, an air-cooled cooler is equipped with fans to draw cool air into the drum. A water-cooled cooler has a water pump and a corresponding pipe system to deliver cooling water to the external wall or jacket of the cylinder.

2. Working Principle

- Heat Exchange Principle: The process is primarily based on conduction and convection. As high-temperature material enters the rotary cooler, the rotating cylinder causes the material to move continuously. The lifting flights scoop and cascade the material, bringing it into full contact with the cooling medium. The cooling medium (e.g., cool air or water) absorbs the material's heat, carrying it away through conduction and convection to lower the material's temperature.

- Material Conveying Principle: The cylinder is installed at an incline. As it rotates, gravity and the lifting flights cause the material to gradually move from the inlet to the outlet, completing the cooling process along the way. The cooler's rotation speed, inclination, and other parameters can be adjusted based on the material's properties and cooling requirements to ensure the optimal residence time and cooling effect.

3. Fields of Application

- Fertilizer Production: Used in the production of compound fertilizers to cool granules after granulation and drying. This lowers the temperature and moisture content, improving the fertilizer's quality and stability for subsequent packaging and storage.

- Metallurgical Industry: Used to cool high-temperature slag and metal granules produced during metal smelting. This helps improve metal recovery and quality, while also facilitating subsequent processing.

- Building Materials Industry: In cement production, for example, it can be used to cool cement clinker, improving its quality and grindability. The heated air from the cooling process is returned to the kiln as secondary recycled air, improving the kiln's thermal efficiency.

- Chemical Industry: Used to cool high-temperature materials produced during various chemical manufacturing processes, such as plastic pellets, rubber granules, and chemical raw materials. This ensures product performance and quality while also improving the safety and stability of the production process.

4. Components of a Rotary Drum Cooler

A rotary drum cooler is primarily composed of the following parts:

- Support System

- Trunnion Roller Assembly: Includes front and rear trunnion roller bases, which are fixed to the foundation to support the cylinder and allow it to rotate in place. Both assemblies consist of a base, bearing housing, and trunnion rollers. The distance between the rollers can be adjusted to change the equipment's height and angle.

- Thrust Rollers: Used to control the axial movement of the cylinder, preventing it from shifting along its axis during rotation to ensure stable operation.

- Drive System

- Motor: Provides the power for the entire cooler. Electromagnetic variable-speed motors are often used to meet different speed and torque requirements.

- Reducer: Reduces the motor's high speed and increases its torque, allowing the cylinder to rotate at the proper speed for an effective cooling result.

- Gear Drive Mechanism: Includes a large gear and a pinion gear, which transmit the power from the reducer to the cylinder, causing it to rotate at a uniform speed.

- Coupling Drive Mechanism: Most rotary coolers use a coupling drive to transmit power from the motor to the reducer, enabling the initial power transfer and speed reduction.

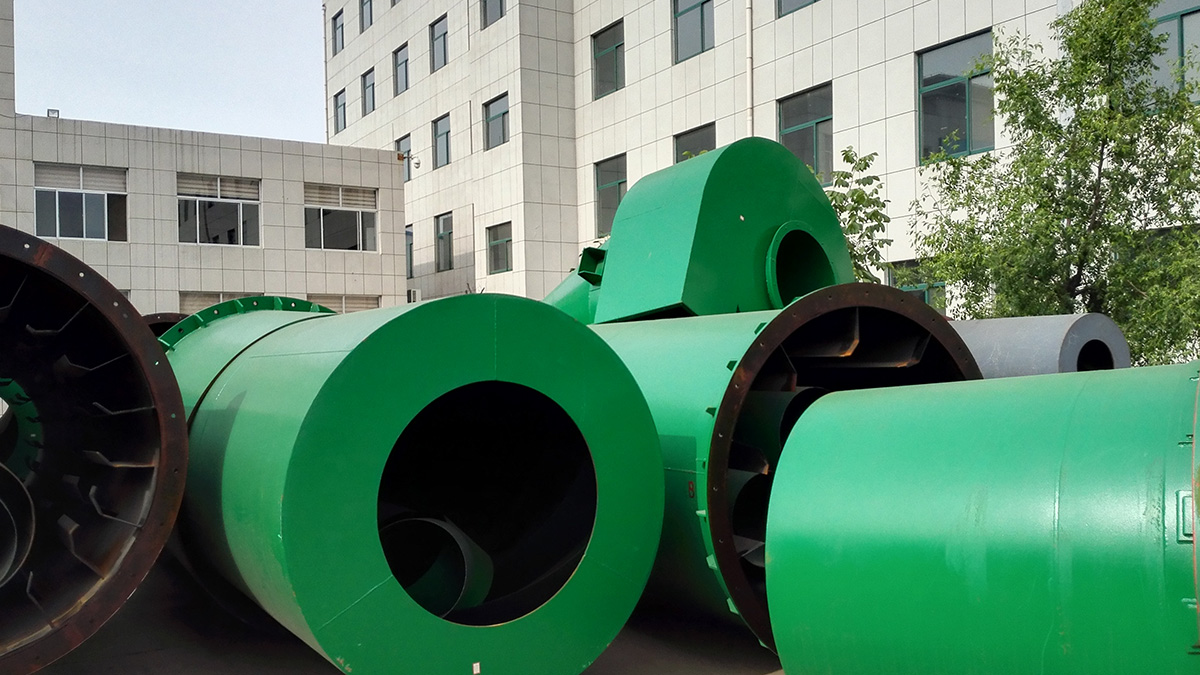

- Cooler Cylinder

- Shell: This is the main body of the cooler. It has roller rings on the outside for support and a gear ring for the drive. Inside, lifting flights are welded to the inner wall. The cylinder is typically installed at a slight incline of about 5° to the horizontal, which helps the material move toward the discharge end under the force of gravity.

- Lifting Flights: Distributed in rows along the inner wall of the cylinder. As the cylinder rotates, the lifting flights continuously lift and cascade the material, increasing the surface area for contact with the cooling medium. This allows the material to fully interact with the cool air or water, facilitating heat exchange and achieving uniform cooling.

- Feeding and Discharge Devices

- Feeding Device: Located at the inlet end of the cylinder, it typically includes an end cap and a feed hopper to uniformly load high-temperature material into the drum. Common hopper shapes include funnel and rectangular, which can be chosen based on material characteristics and production needs.

- Discharge Device: Located at the outlet end of the cylinder, it collects the cooled material. It typically includes a discharge end cap that fits over the outlet end of the cylinder, with a discharge opening at the bottom for easy material removal.

- Cooling System

- Air-Cooling System: Includes a fan and air ducts. A fan connected to the outlet at the front of the machine continuously draws ambient air from the tail end of the cooler. This air flows through the material bed in a counter-current or co-current direction, facilitating direct heat exchange to achieve the cooling objective.

- Water-Cooling System: A water-cooling system may be used for cooling materials at extremely high temperatures. It typically includes a circulating water jacket and corresponding piping.

- Sealing Devices: Used to seal the gaps between the cylinder and the feeding/discharge devices, as well as other components. This prevents cold air or cooling water leaks, while also containing material and ensuring the cooler's proper function and a clean working environment.

5. How to Choose a Rotary Drum Cooler

Choosing a rotary cooler requires a comprehensive evaluation of your specific production needs, material characteristics, equipment performance, and operating costs. Here are the key selection criteria to help you make an accurate choice:

- Understand Your Core Needs: Material and Process The core function of a rotary cooler is to cool high-temperature materials like cement clinker, slag, and fertilizer. Therefore, material characteristics and process requirements are the top priorities.

- Material Characteristics:

- Physical State: Is it granular, powdered, or lumpy? Is it sticky (to prevent clumping)? What's the particle size (which affects fill rate and heat exchange efficiency)?

- Chemical Properties: Is it corrosive (e.g., high-sulfur materials require a stainless steel or anti-corrosion-coated cylinder)? Is it at an extremely high temperature (e.g., over 1000°C requires a high-temperature resistant liner)?

- Hardness and Abrasiveness: For hard materials like metal slag, check if the cylinder has a wear-resistant liner (e.g., high-chromium cast iron, wear-resistant ceramic) to avoid frequent replacements.

- Process Requirements:

- Throughput: Clearly define the amount of material you need to cool per hour (e.g., 50t/h, 200t/h). This ensures the equipment size is a good match—too small, and you won't meet capacity; too big, and you waste energy.

- Cooling Target: What is the desired final temperature of the material (e.g., ≤60°C)? This will determine the required heat exchange area and cooling intensity.

- Material Characteristics:

- Focus on Core Equipment Performance: Key Components Determine Stability The core performance of a rotary cooler is determined by its cylinder, drive system, and cooling system. You should evaluate each of them carefully:

- Cylinder Design:

- Specifications: The diameter, length, and rotation speed must match the required material residence time (cooling time = cylinder length / (speed × pitch)). Generally, a lower speed and longer cylinder provide more thorough cooling, but you must balance this with throughput.

- Internal Structure: Does it have lifting flights (to lift the material and increase the heat exchange area)? Are the angle and arrangement of the flights appropriate for the material (e.g., anti-stick flights for sticky materials, uniform distribution flights for granular materials)?

- Drive System:

- Drive Type: Choose a stable motor + reducer drive (from a reputable brand like SEW or Guomao) to avoid downtime due to transmission failure.

- Overload Protection: Is it equipped with an overload protection device (like a torque limiter) to prevent motor damage in case of a material jam?

- Cooling System:

- Cooling Method: Will you use air cooling (suitable for small to medium throughput, no water required, but lower heat exchange efficiency) or water cooling (suitable for high throughput, high efficiency, but requires consideration of water quality to prevent scaling)?

- Heat Exchange Efficiency: Consider the temperature difference between the inlet and outlet of the cooling air/water and the contact area between the material and the cooling medium (e.g., is the cylinder treated for anti-corrosion and heat conduction?).

- Cylinder Design:

- Consider Operating Costs: Energy and Maintenance

- Energy Consumption: Compare the energy consumption per unit of cooled material (e.g., kWh/t). Prioritize equipment with a variable-frequency drive (which can adjust speed based on material volume, saving 10%-20% on energy) and an efficient heat exchange design (like a jacketed cooling cylinder).

- Maintenance Costs:

- Wearing Parts Lifespan: Check the replacement cycle of wear-resistant liners and seals (which prevent dust leaks). Choose a durable material (like wear-resistant steel) and a design that is easy to disassemble (to reduce maintenance downtime).

- Ease of Cleaning: Is the water-cooling system easy to clean for scale buildup? Does the air-cooling system come with dust collection (to prevent dust from clogging the air ducts)?

- Evaluate the Manufacturer: Customization and Service are Key

- Customization Capability: Different materials have vastly different properties, so the manufacturer must be able to provide custom designs (e.g., special material cylinders, anti-stick structures). Avoid a "one-size-fits-all" approach.

- Case Studies and Reputation: Prioritize manufacturers with experience in your industry (e.g., choose a brand that has built coolers for cement plants). Visit a site to see the equipment in operation (e.g., check its failure rate and cooling performance).

- After-Sales Service: Confirm if they provide installation, commissioning, operational training, and a supply of wearing parts. Localized service is a plus, as it can reduce waiting time for repairs.

- Compliance and Compatibility: Don't Overlook the Details

- Environmental Compliance: If the cooling process generates dust, confirm that the equipment includes an efficient dust collection device (like a pulse dust collector) to meet local environmental standards (e.g., dust emissions ≤30mg/m³).

- Site Compatibility: Check the equipment's footprint (length x width) and installation height to ensure it fits your facility's space. Confirm if a special foundation is needed (e.g., heavy-duty equipment requires reinforced concrete).

In summary, the core logic for selecting a rotary drum cooler is "material match → performance meets standards → controllable costs → reliable service." You must combine this with your specific production scenario. Avoid blindly chasing "large capacity" or "low price" and prioritize the balance between stability, efficiency, and long-term operating costs.

6. Rotary Drum Cooler Pricing

The price is determined by factors such as product specifications, material of construction, and capacity, based on customer requirements. Please contact our sales team for a specific quote.

7. Company and Product Introduction

Founded in 1997, Tai'an Hongxin Environmental Protection Technology Co., Ltd. is located at the foot of Mount Tai, one of China's most famous mountains. Our facility spans 100,000 square meters, with 66,000 square meters of floor space. We hold an A2 pressure vessel manufacturing license and are ISO9001 certified. We are a high-tech enterprise in Shandong Province, a strategic partner of the Shandong Academy of Agricultural Sciences, and a member of the National Fertilizer Industry Technology Innovation Alliance.

Our team consists of 216 technical staff and over 100 sets of large, precision, and specialized processing equipment. Our professional technical and manufacturing teams provide comprehensive services, including technical consultation, process design, installation, commissioning, personnel training, and full turnkey project solutions. We also guarantee excellent after-sales service. Our products are sold both domestically and internationally, with exports to countries like Indonesia, the UAE, Malaysia, Vietnam, Bangladesh, and Myanmar.

Specification

| Specifications | Cylinder | Capacity | External dimensions L*W*H | |||

| Inner diameter | Length | Rotating Speed | Power | |||

| mm | mm | r/min | Kw | t/h | mm | |

| GH1212 | 1200 | 12000 | 5.5 | 7.5 | 1-3 | 13350*1600*2200 |

| GH1515 | 1500 | 15000 | 5 | 15 | 2-6 | 16000*1900*2500 |

| GH1818 | 1800 | 18000 | 4.5 | 22 | 5-8 | 19000*2200*2800 |

| GH2020 | 2000 | 20000 | 4 | 30 | 6-10 | 21350*2600*3200 |

| GH2222 | 2200 | 22000 | 3.5 | 37 | 10-14 | 23350*2800*3400 |

| GH2424 | 2400 | 24000 | 3.2 | 55 | 14-18 | 25400*3220*3900 |

| GH2626 | 2600 | 26000 | 3.2 | 75 | 15-20 | 29500*3450*4200 |

| GH2828 | 2800 | 28000 | 3 | 90 | 18-22 | 29700*3500*4800 |

| GH3030 | 3000 | 30000 | 3 | 110 | 20-26 | 32000*4150*5000 |